stainless drilling tools

Drilling is one of the most common operations in the world of sheet metal and plate manufacturing, The last 30 years have seen the emergence of laser, plasma, and waterjet cutting technologies that can produce holes of various tolerances in a lot of materials. Manufacturers have a plethora of choices when it comes to holemaking.

Laser drilling has become a widely used manufacturing solution in many industries. The primary advantage of laser drilling is that it is a non-contact process and hence mechanical wear of the drilling tool is not an issue.

Compared to other drilling methods, lasers offer superior speed and precision while lowering operating costs. As a result, they’re finding a home in a variety of industries, from automotive to medical device manufacturing.

Why choose the laser cutting machine to drill?

Laser cutters offer several advantages in metal drilling, including:

-

Precision: Laser cutters can produce extremely precise holes in metal, with tolerances as small as a few microns. This precision is due to the high power and focus of the laser beam.

-

Speed: Laser drilling can be much faster than traditional drilling methods, particularly when drilling multiple holes or intricate patterns. This can lead to increased productivity and efficiency.

-

Versatility: Laser cutters can drill a wide range of metals, including steel, aluminum, copper, and brass. They can also drill through various thicknesses of metal.

-

Flexibility: Laser cutters can produce holes of different shapes and sizes, including round, square, and complex shapes. They can also be programmed to drill holes at different angles and depths.

-

Minimal heat-affected zone: Laser drilling produces minimal heat-affected zones around the drilled holes, which reduces the risk of warping or deformation in the surrounding metal.

-

Minimal tool wear: Unlike traditional drilling methods that require drill bits to be replaced frequently, laser drilling uses a non-contact process that produces minimal tool wear, leading to longer tool life.

Overall, laser cutting offers several advantages over traditional drilling methods, making it an ideal choice for high-precision and high-volume metal drilling applications.

Comparison of different drilling tools

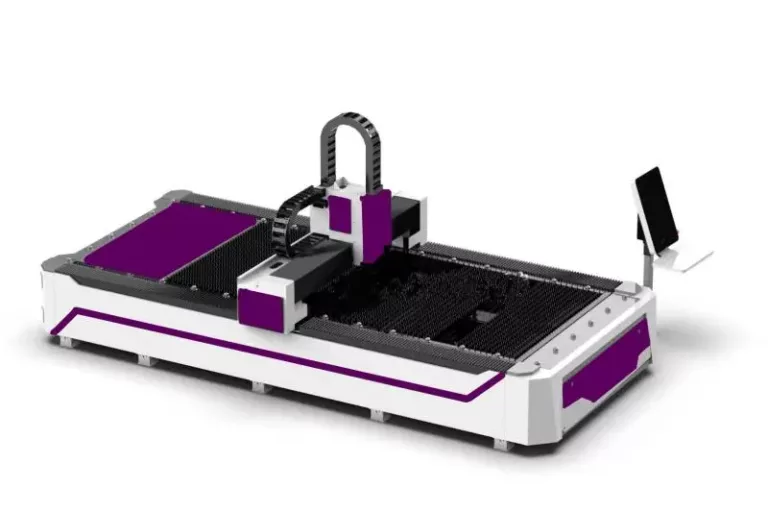

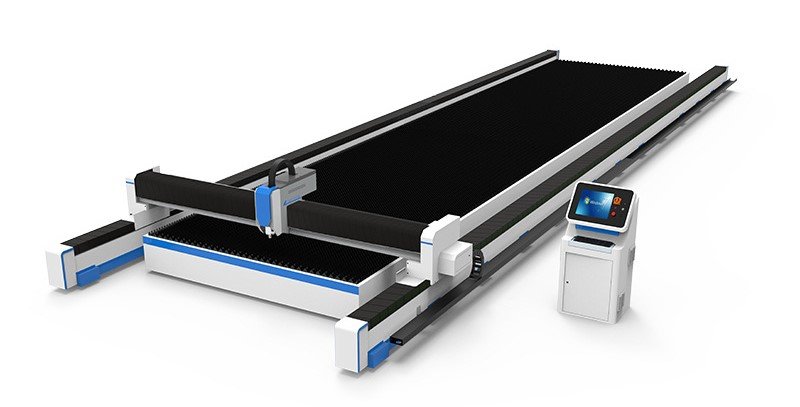

Laser drilling cutting

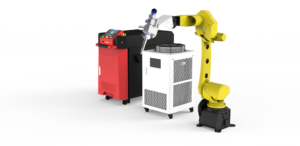

Plasma cutting with drilling system

which tools you will choose?