A laser cutting machine can cut steel channels with a high level of precision and accuracy. Here are the steps involved in the laser cutting process for steel channels:

-

Programming: First, the design for the steel channel is programmed into the laser cutting machine using specialized software. The software takes into account the dimensions and tolerances required for the finished product.

-

Material Preparation: The steel channel is prepared by cleaning and preparing the surface to ensure that it is free of contaminants and any protective coatings are removed.

-

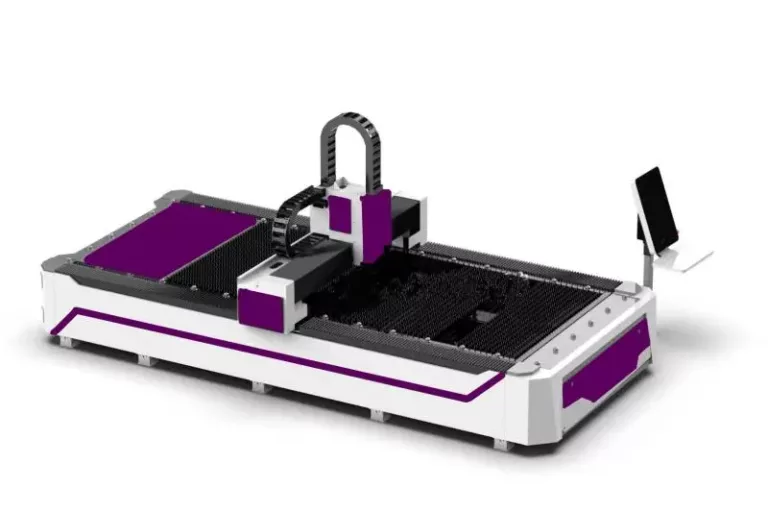

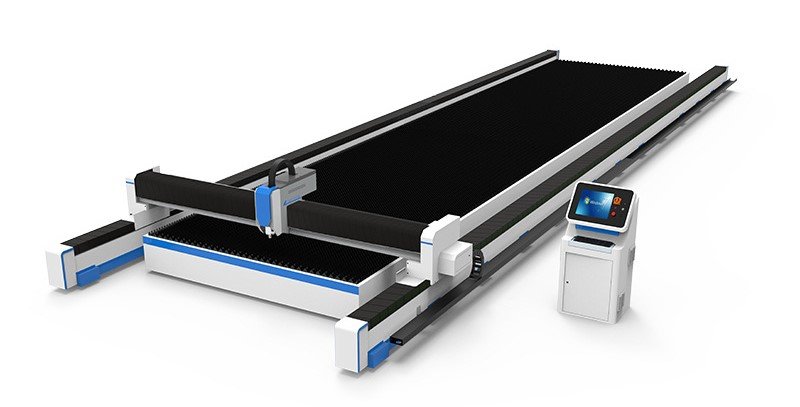

Laser Cutting: The laser cutting machine uses a high-powered laser beam to cut through the steel channel. The laser beam is generated by a resonator and is directed by a series of mirrors to the cutting head. The cutting head contains a focusing lens that focuses the laser beam to a small point on the surface of the steel channel, creating a localized area of intense heat.

-

Cutting Path: The laser cutting machine follows a pre-programmed cutting path to create the required shape and dimensions for the steel channel. The cutting head moves along the cutting path, melting and vaporizing the steel material as it goes.

-

Coolant: During the cutting process, a coolant is sprayed onto the steel channel to help dissipate the heat and prevent the material from warping or distorting.

-

Finishing: Once the cutting process is complete, the steel channel may require finishing to remove any burrs or sharp edges created by the cutting process. This can be done using a deburring tool or a grinding wheel.

Overall, laser cutting is an efficient and precise cutting method for steel channels, offering a high level of accuracy and flexibility for a variety of designs and applications.

There are several advantages of using a laser cutter for steel channel cutting

-

Precision: Laser cutting machines offer an extremely high level of precision and accuracy, which is essential for cutting steel channels with complex designs and tight tolerances. The laser beam can create intricate shapes and smooth edges, with minimal material wastage.

-

Speed: Laser cutting machines are capable of cutting through steel channels at high speeds, making them an efficient and cost-effective cutting method for high-volume production.

-

Versatility: Laser cutting machines can cut through a wide range of materials, including steel, stainless steel, and aluminum. This makes them a versatile cutting tool for a variety of applications in the steel industry.

-

Flexibility: Laser cutting machines can be programmed to cut a variety of shapes and designs, from simple geometric shapes to complex designs with intricate details. This makes them ideal for producing custom steel channels for specific applications.

-

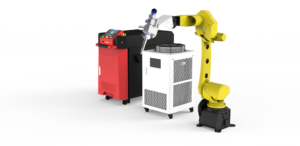

Automation: Laser cutting machines can be fully automated, reducing the need for manual labor and increasing productivity. This allows for faster turnaround times and lower production costs.

-

Reduced Waste: Laser cutting machines produce minimal waste compared to traditional cutting methods such as sawing or drilling, resulting in significant cost savings in material usage.

Overall, laser cutting machines offer numerous advantages for steel channel cutting, including precision, speed, versatility, flexibility, automation, and reduced waste. These benefits make them an attractive option for the steel industry, where accuracy and efficiency are essential for meeting production demands.