H-beam steel is widely used in the construction and manufacturing industries due to its high strength-to-weight ratio and load-bearing capacity. Plasma cutting is a popular method for cutting H-beams due to its precision, speed, and cost-effectiveness. In this article, we will discuss the plasma cutting process for H-beam steel.

Material Preparation: The first step in the plasma cutting process is to prepare the H-beam steel material. This includes cleaning the surface to remove any contaminants or debris that could interfere with the cutting process.

Setting Up the Plasma Cutter: The plasma cutter is set up by selecting the appropriate settings for the material being cut, such as the cutting speed, gas flow rate, and power level. The plasma cutter is then attached to the computerized numerical control (CNC) system, which will guide the cutter along the cutting path.

Cutting Path: The CNC system uses the programmed design to guide the plasma cutter along the cutting path, which is pre-determined based on the design requirements. The plasma cutter creates a high-temperature plasma arc, which melts the H-beam steel material along the cutting path.

Gas Assistance: During the cutting process, a gas is used to assist with the cutting process and protect the cutting surface. This gas can be oxygen, nitrogen, or a combination of both. The gas also helps to remove the molten material from the cutting surface, which reduces the risk of slag buildup.

Cooling: Once the cutting process is complete, the H-beam steel material is cooled using a coolant, such as water or air. This helps to prevent warping or distortion of the material due to the high temperatures generated during the cutting process.

Finishing: The H-beam steel material may require finishing, such as deburring or grinding, to remove any sharp edges or burrs created during the cutting process. This can be done manually or using specialized equipment.

Plasma cutting offers several advantages over traditional cutting methods, such as sawing or drilling. These advantages include faster cutting speeds, higher precision, and lower material wastage. Plasma cutting is also suitable for cutting a wide range of materials, including steel, stainless steel, and aluminum.

In conclusion, plasma cutting is an efficient and cost-effective method for cutting H-beam steel. By following the plasma cutting process outlined above, manufacturers can produce high-quality H-beam steel components with precision and accuracy.

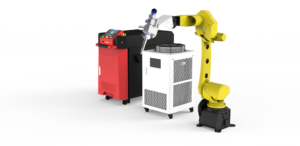

And you can choose Laser cutting machine for your work