The advantage of laser metal sheet cutting machine’ controller

The controller of a metal laser cutting machine plays a crucial role in the overall performance and efficiency of the machine. Here are some advantages of a well-designed controller:

Precision and Accuracy: The controller of a laser cutting machine ensures precise and accurate positioning of the laser beam. It receives instructions from the computer numerical control (CNC) system and translates them into precise movements of the laser head and the metal sheet. A high-quality controller can achieve extremely fine positioning, resulting in precise cuts and intricate designs.

Speed and Efficiency: A sophisticated controller can optimize the cutting path and coordinate the movements of the laser head and the metal sheet to minimize idle time and maximize cutting speed. It can calculate the most efficient cutting sequences, reducing production time and improving overall efficiency.

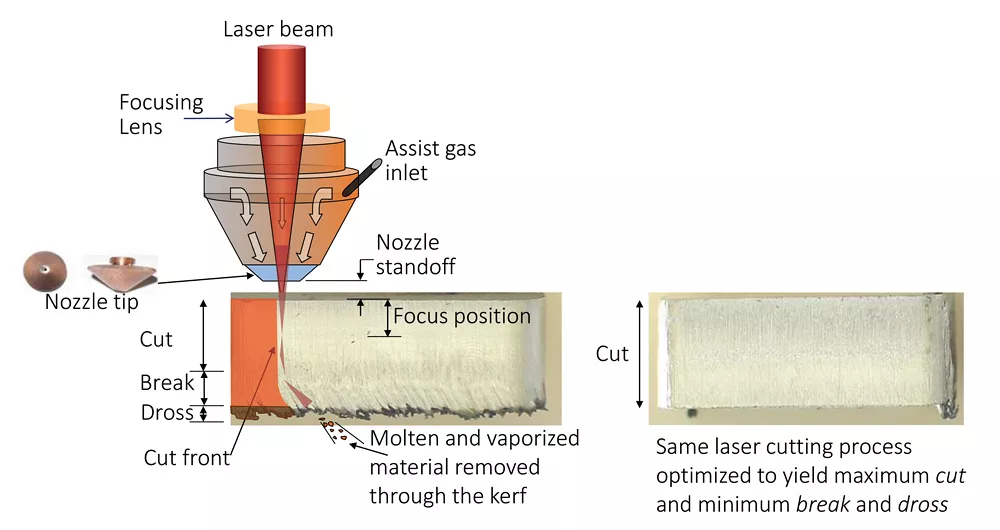

Flexibility and Versatility: Modern laser cutting machine controllers offer a range of programming and customization options. They allow operators to adjust parameters such as cutting speed, power output, assist gas flow, and focus depth, depending on the specific requirements of the metal being cut. This flexibility enables the machine to handle a wide variety of materials and thicknesses.

User-Friendly Interface: An intuitive and user-friendly interface on the controller makes it easier for operators to interact with the machine. It provides clear and concise information about the cutting process, machine status, and any potential errors or warnings. A well-designed interface enhances productivity and reduces the learning curve for operators.

Automation and Integration: Advanced controllers can integrate with other systems and software, such as CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing) software and production management systems. This integration enables seamless data transfer, automated programming, and real-time monitoring, improving workflow efficiency and reducing manual intervention.

Diagnostic and Maintenance Features: A controller with built-in diagnostic tools and maintenance features can help identify issues or potential problems with the machine. It can monitor various parameters, such as laser power, gas pressure, and temperature, and provide real-time feedback to operators. Early detection of issues allows for timely maintenance, reducing downtime and optimizing machine performance.

Overall, a well-designed and advanced controller for a metal laser cutting machine enhances precision, speed, flexibility, user experience, and maintenance capabilities. It plays a vital role in maximizing the productivity and efficiency of the machine while ensuring high-quality cuts and reliable operation.

why choose metal cutting laser machines

Fiber laser cutting machine melt and pierce metals by uses a type of solid-state concentrated laser, When this powerful laser hits the metal surface, the high-intensity light is absorbed and converted into heat, which melts the surface. it is a precise and efficient cutting tool.

The Fiber laser cutters can cut a range of materials and thicknesses depending on laser power. maxmum cutting thickness can be 40mm.