Different H beam cutting tools in steel structure

H beams are widely used in the steel structure industry as they offer a high strength-to-weight ratio and can support heavy loads over long spans. Cutting H beams to size is an essential step in the production of steel structures, such as bridges, buildings, and industrial facilities. Here are some common methods for cutting H beams in the steel structure industry:

-

CNC Plasma Cutting: CNC plasma cutting is a computer-controlled cutting process that uses a plasma torch to cut through steel materials. It is a precise and efficient cutting method that can cut through thick steel materials quickly and accurately. CNC plasma cutting is often used to cut H beams to size and shape.

-

Bandsaw Cutting: Bandsaw cutting is a manual cutting process that uses a saw blade to cut through steel materials. It is a slower cutting process than CNC plasma cutting, but it is suitable for cutting smaller quantities of H beams.

-

Oxy-Fuel Cutting: Oxy-fuel cutting is a process that uses a flame to heat and melt the steel material. The molten steel is then blown away by a jet of oxygen gas. Oxy-fuel cutting is a versatile cutting process that can cut through thick steel materials. However, it is a slower process than CNC plasma cutting.

-

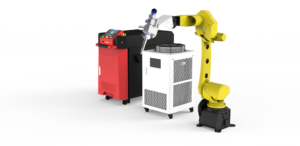

Laser Cutting: Laser cutting is a precise cutting process that uses a high-powered laser to cut through steel materials. It is a fast and efficient cutting method, but it is more expensive than other cutting methods.

Overall, the method used to cut H beams in the steel structure industry will depend on factors such as the required precision, speed, and cost-effectiveness of the cutting process. CNC plasma cutting is a popular choice due to its precision, speed, and cost-effectiveness, but other cutting methods may be more suitable for certain applications.

Why choose the plasma cutting machine?

There are several reasons why a CNC plasma cutter is an excellent choice for cutting H beams:

Precision: A CNC plasma cutter is designed to cut through steel materials with extreme precision. It can follow a pre-programmed cutting path to make accurate cuts with minimal wastage. This makes it an ideal choice for industries where precision is critical, such as in the production of steel structures.

Speed: A CNC plasma cutter is known for its high speed, which makes it an efficient tool for large-scale production. It can cut through thick steel materials quickly and accurately, saving time and increasing productivity.

Versatility: A CNC plasma cutter can cut through a wide range of materials, including stainless steel, aluminum, and other metals. This makes it a versatile tool for a variety of applications in the steel industry.

Cost-effective: Compared to traditional cutting methods, such as manual cutting or oxy-fuel cutting, a CNC plasma cutter is more cost-effective. It can produce accurate cuts with minimal wastage, reducing material costs and saving time in the production process.

Customization: With the help of specialized software, a CNC plasma cutter can be programmed to create customized cutting paths. This allows manufacturers to produce unique and intricate designs for their steel structures, which would be difficult or impossible to achieve with traditional cutting methods.

Overall, a CNC plasma cutter is an excellent choice for cutting H beams due to its precision, speed, versatility, cost-effectiveness, and customization capabilities.