A 12000W laser cutting machine is a very powerful cutting tool, capable of cutting through a wide range of materials, including metals, plastics, and woods. Cutting 30mm thick material with a laser requires a high-powered machine like this one, but it also depends on the type of material being cut and the specific characteristics of the laser itself.

Assuming you’re cutting a metal like steel, which is a common material for laser cutting, a 12000W laser should be able to easily cut through 30mm thick sheets with high precision and accuracy. However, it’s important to note that the speed and quality of the cut will also depend on the specific parameters used for the laser cutting process, such as the cutting speed, focus, and gas pressure.

If you’re using a different material, or if the specific conditions of the cutting process vary, the requirements and capabilities of the laser cutting machine may also change. In any case, it’s always important to consult with a professional or a representative of the laser cutting machine manufacturer to ensure that you’re using the machine safely and effectively.

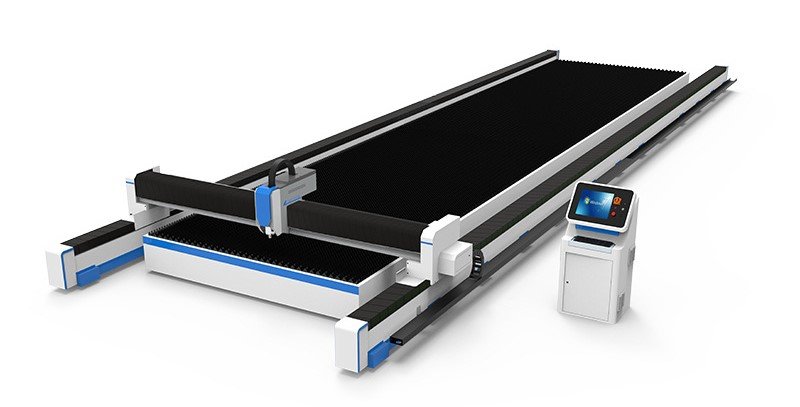

12000KW/3000KW HOTEST MACHINE -GF

why choose 12KW laser cutting machine

There are several reasons why one might choose a 12KW laser cutting machine, including:

-

Increased cutting speed: A 12KW laser cutting machine is capable of cutting materials at a faster speed compared to lower power machines. This means that larger or thicker materials can be cut quickly and efficiently, which can be particularly useful in industries such as aerospace, automotive, and construction.

-

Increased cutting depth: The higher power of a 12KW laser cutting machine allows for increased cutting depth, which means that thicker materials can be cut more easily. This is particularly useful in industries where thick metals or other materials are commonly used.

-

Improved precision: Higher power laser cutting machines can produce cleaner, more precise cuts due to their increased power and ability to cut through materials more efficiently. This can be particularly important in industries such as electronics or medical device manufacturing, where precision is critical.

-

Versatility: A 12KW laser cutting machine is capable of cutting a wide range of materials, including metals, plastics, ceramics, and composites. This versatility makes it a useful tool in a variety of industries.

-

Cost savings: Although a 12KW laser cutting machine may have a higher initial cost compared to lower power machines, it can result in significant cost savings over time due to its increased cutting speed and efficiency. This can lead to reduced labor costs and increased production output.