I. Overview

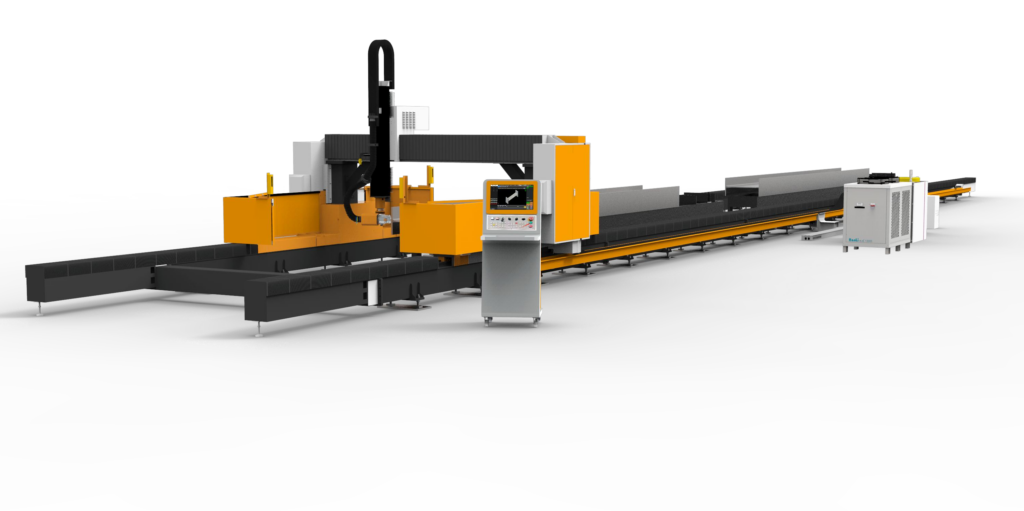

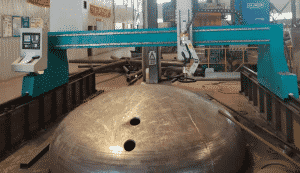

These operation procedures apply to the use of laser tube cutting machines, aiming to ensure operator safety and the proper functioning of the equipment. Operators must strictly follow these procedures to minimize accidents and unexpected incidents.

II. Operating Procedures

Equipment Inspection:

Before using the laser tube cutting machine, the operator should carefully check whether all parts of the equipment are intact and secure. Any issues must be reported to maintenance personnel immediately and should only be operated after repairs are completed.Wearing Personal Protective Equipment (PPE):

Operators must wear appropriate PPE, including safety goggles, earplugs, and protective gloves. These protective measures help prevent injuries from laser radiation, noise, and cutting debris.Setup and Adjustment:

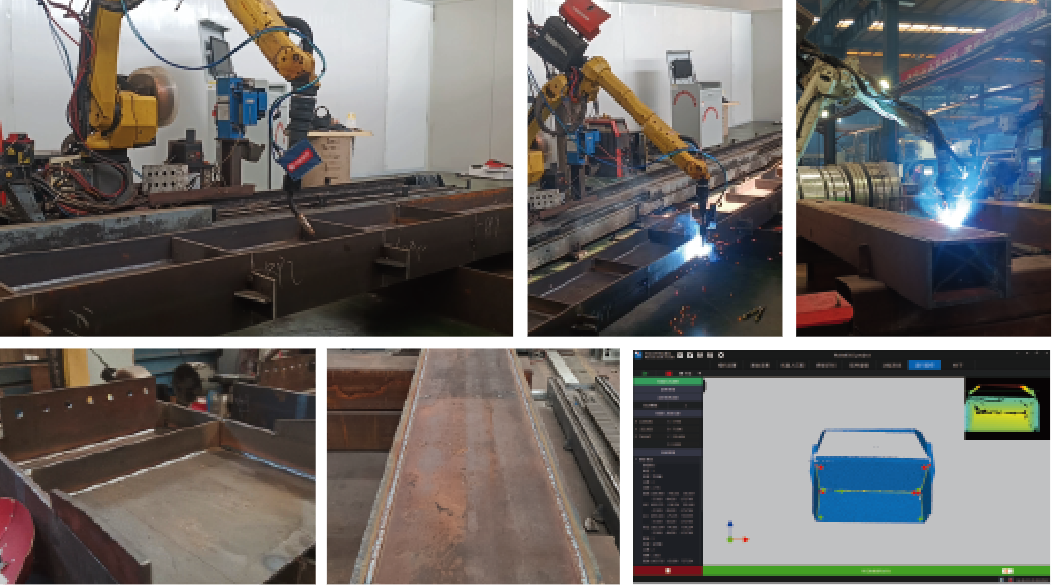

Before operation, the operator should adjust the machine settings according to work requirements. Ensure that the cutting tool, cutting speed, and cutting depth are correctly set. A test run should be performed to confirm accuracy and stability.Safe Cutting Preparation:

Before starting the cutting process, ensure the work area is clean and free from obstacles. Adjust the cutting position as required, ensuring the tube is properly secured and aligned to prevent cutting deviations or breakage.Standard Operating Practices:

Operators must follow standard procedures for cutting operations, maintaining coordination between manual and automatic processes. Stay alert at all times, monitor the machine’s performance and cutting results, and promptly address any abnormalities.Post-Cutting Procedures:

After completing the cutting process, turn off the machine’s power and perform necessary cleanup. Properly dispose of cutting waste and debris, and clean the workbench and surrounding area to eliminate safety hazards.

III. Safety Precautions

- Do not modify machine parameters or cutting settings without authorization; follow the instructions in the user manual.

- Temporary repairs and modifications to the machine are prohibited; all repairs must be carried out by qualified personnel.

- Avoid touching or operating the machine arbitrarily during cutting to prevent accidents.

- Keep fingers or other objects away from the cutting area to prevent injuries from cutting tools and laser beams.

- Maintain focus and a stable posture during operation; avoid distractions or engaging in non-work-related activities.

- If any abnormalities or malfunctions occur, stop the machine immediately and report them to maintenance personnel for inspection and repair.

IV. Emergency Handling

- Operators must be familiar with the location and operation of the emergency stop device.

- In case of an emergency or accident, immediately press the emergency stop button, disconnect the power supply, and report to the relevant personnel and maintenance team.

- For fire, electrical leakage, or other emergencies, follow fire safety and emergency response procedures to ensure personal and equipment safety.

V. Training and Evaluation

- Operators must receive proper training to become familiar with machine operation, safety precautions, and standard procedures.

- Regular assessments of safety knowledge and operational skills should be conducted to ensure operators maintain a high level of proficiency and safety awareness. Additional training should be provided when necessary.

Note: This document is for reference only. Please follow the machine’s user manual and relevant regulations for actual operation.