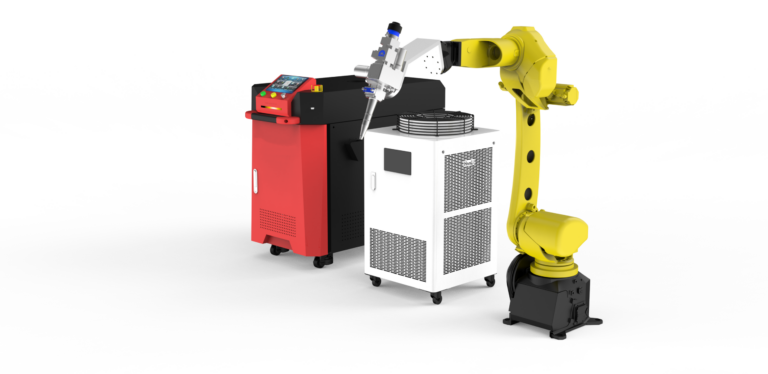

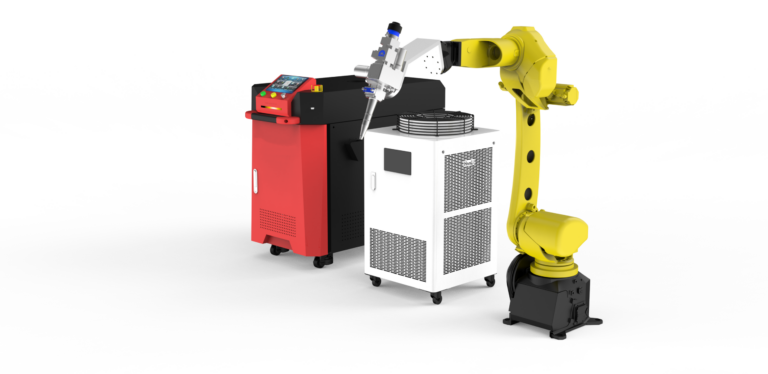

Fiber laser system robot

6 axis robot+fiber laser system The combination of a fiber laser and a 6-axis robot allows for the integration of cutting and welding, offering the

We use analytical cookies to improve your experience on our website

Laser cutting machines are often chosen to cut H beams because of their precision, speed, and versatility. H beams are commonly used in construction and manufacturing, and they can be difficult to cut with traditional cutting methods due to their size and shape. Laser cutting machines can effectively cut H beams with high accuracy and speed, producing clean edges and minimizing material waste.

Additionally, laser cutting machines offer several advantages over other cutting methods. They use a focused beam of light to cut through material, which means that there is no physical contact between the cutting tool and the material being cut. This reduces the risk of damage to the material and allows for more precise cuts. Laser cutting machines are also highly automated, which means that they can be programmed to cut complex shapes and patterns with minimal human intervention.

The use of laser technology for cutting steel beams offers several advantages, including high precision, speed, and accuracy. Laser cutting machines can cut complex shapes and patterns quickly and easily, and can also be programmed to cut multiple parts at once, making them ideal for high-volume production.

However, CNC laser cutting machines can also be expensive and require specialized training to operate. Additionally, they may produce hazardous fumes and require appropriate ventilation and safety measures to prevent accidents.

Overall, laser cutting machines are an efficient and effective option for cutting H beams, providing high-quality results while reducing material waste and production time.

Power: The power of the laser will determine the thickness of the H beam that can be cut. Consider the thickness of the H beams you will be cutting and select a machine with appropriate laser power.

Table size: The size of the machine’s cutting table should be large enough to accommodate the size of the H beams you will be cutting.

Accuracy: Look for a machine with high accuracy and precision to ensure consistent, quality cuts.

Automation: CNC laser cutter machines can be fully automated, which can improve efficiency and reduce the risk of errors. Consider the level of automation you require.

Maintenance: Consider the ease of maintenance and the availability of spare parts and technical support.

Cost: Determine your budget and consider the cost of the machine, as well as operating and maintenance costs.

Reputation: Choose a machine from a reputable manufacturer with a proven track record for quality and reliability.

6 axis robot+fiber laser system The combination of a fiber laser and a 6-axis robot allows for the integration of cutting and welding, offering the

plasma cutting machine and laser cutting machine in beam cutting Plasma Beam Cutting Machine: A plasma beam cutting machine is a type of CNC (Computer Numerical Control)

Auxiliary gases in laser cutting Air cutting is widely loved by laser processing customers because of its low cost, which only requires an air compressor