Revolutionize Your Welding Process with Laser Robot Welding Machines

In today’s fast-paced manufacturing industry, precision, efficiency, and automation are key to staying competitive. Laser Robot Welding Machines are transforming the welding landscape, offering unmatched accuracy, speed, and versatility. Whether you’re in automotive, aerospace, electronics, or heavy machinery, integrating a laser robot welding system into your production line can take your operations to the next level.

Why Choose Laser Robot Welding Machines?

- Unparalleled Precision

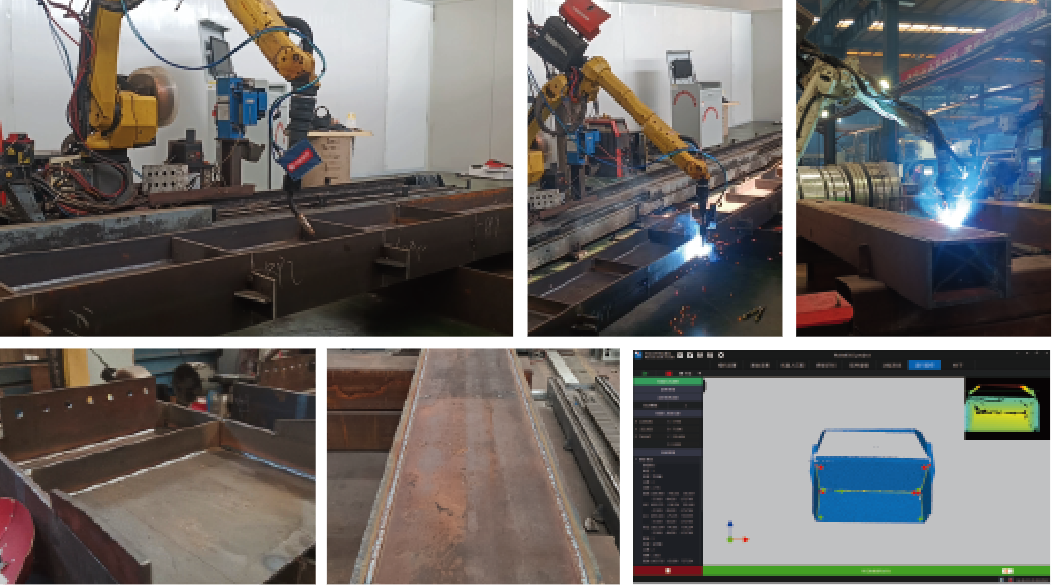

Laser welding robots deliver micron-level accuracy, ensuring flawless welds even on the most complex geometries. This precision minimizes material waste and reduces the need for rework, saving time and costs. - Increased Productivity

With high-speed welding capabilities, laser robots significantly reduce cycle times. Automated systems can operate 24/7, boosting output and meeting tight deadlines without compromising quality. - Versatility Across Materials

From stainless steel and aluminum to titanium and copper, laser welding machines handle a wide range of materials with ease. This makes them ideal for diverse industries and applications. - Enhanced Safety

By automating the welding process, laser robots reduce human exposure to hazardous environments, sparks, and fumes. This creates a safer workplace while maintaining consistent quality. - Cost-Effective in the Long Run

Although the initial investment may seem high, the long-term savings in labor, material efficiency, and reduced downtime make laser robot welding machines a smart financial choice.

Applications of Laser Robot Welding Machines

- Automotive Industry: Perfect for welding car bodies, exhaust systems, and battery components with high precision.

- Aerospace: Ideal for joining lightweight materials and critical components that demand zero defects.

- Electronics: Ensures delicate, high-quality welds for small components like sensors and circuit boards.

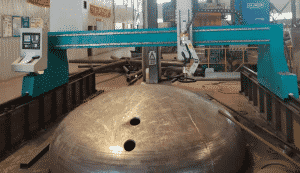

- Heavy Machinery: Handles thick materials and large structures with ease, ensuring durability and strength.

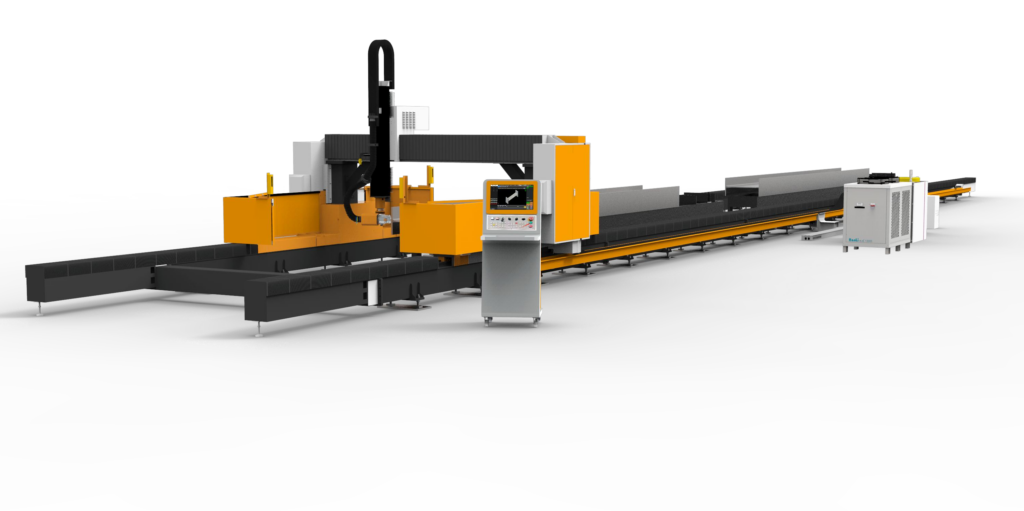

Key Features to Look for in a Laser Robot Welding Machine

- High-Power Laser Source: Ensures deep penetration and fast welding speeds.

- Advanced Control Systems: User-friendly interfaces for easy programming and operation.

Flexible Robotic Arms:Multi-axis movement for accessing hard-to-reach areas.- Real-Time Monitoring: Sensors and cameras for quality control and process optimization.

- Customizable Solutions: Tailored to meet specific industry needs and production requirements.