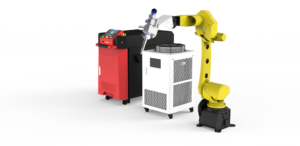

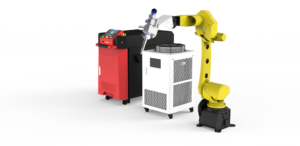

Fiber laser system robot

6 axis robot+fiber laser system The combination of a fiber laser and a 6-axis robot allows for the integration of

We use analytical cookies to improve your experience on our website

H beam plasma cutting machine is a type of CNC (computer numerical control) machine specifically designed for cutting H-beams or I-beams using plasma technology. H-beams and I-beams are widely utilized in the construction industry for building frames, supports, and various structures due to their strength and versatility.

Plasma cutting is a process that uses a high-temperature plasma arc to melt and cut through metal. The H beam plasma cutting machine is equipped with a plasma torch that creates the plasma arc, and a CNC system that controls the movement of the torch to make precise cuts.

The H beam plasma cutting machine can be programmed to cut a variety of shapes and sizes in H-beams and I-beams. It is a highly efficient and accurate cutting method that produces clean and precise cuts without the need for secondary processing.

Overall, the H beam plasma cutting machine is a versatile and reliable tool for metal fabrication, construction, and other industries that require precise and efficient cutting of H-beams and I-beams.

Cutting an H-beam requires the use of appropriate tools and methods to ensure clean and accurate cuts. The best way to cut an H-beam depends on the equipment and resources available to you. Here are some common methods for cutting H-beams:

Bandsaw: Bandsaws are commonly used for cutting metal and are suitable for cutting H-beams. They offer more control and precision than abrasive saws, resulting in smoother cuts. Proper clamping and support are also necessary when using a bandsaw.

Oxy-Fuel Cutting: Oxy-fuel cutting involves using a torch that mixes oxygen with a fuel gas (acetylene, propane, or natural gas) to create a high-temperature flame. The intense heat melts the metal, and a high-pressure stream of oxygen blows away the molten metal, cutting through the H-beam. Oxy-fuel cutting is suitable for thicker H-beams but may not provide the same level of precision as sawing methods.

Plasma Cutting: Plasma cutting utilizes a high-velocity jet of ionized gas (plasma) to melt and cut through the metal. It is an efficient method for cutting thicker H-beams and can provide relatively precise cuts.

Waterjet Cutting: Waterjet cutting uses a high-pressure stream of water mixed with an abrasive material to cut through the H-beam. Waterjet cutting is precise and does not create heat-affected zones, making it suitable for cutting various materials and thicknesses.

Laser Cutting: Laser cutting employs a focused laser beam to melt and vaporize the metal, creating a clean and accurate cut. Laser cutting is highly precise and suitable for cutting thin to medium thickness H-beams.

6 axis robot+fiber laser system The combination of a fiber laser and a 6-axis robot allows for the integration of

plasma cutting machine and laser cutting machine in beam cutting Plasma Beam Cutting Machine: A plasma beam cutting machine is a type

Auxiliary gases in laser cutting Air cutting is widely loved by laser processing customers because of its low cost, which

how to keep the safe when purchase the cnc cutting machine