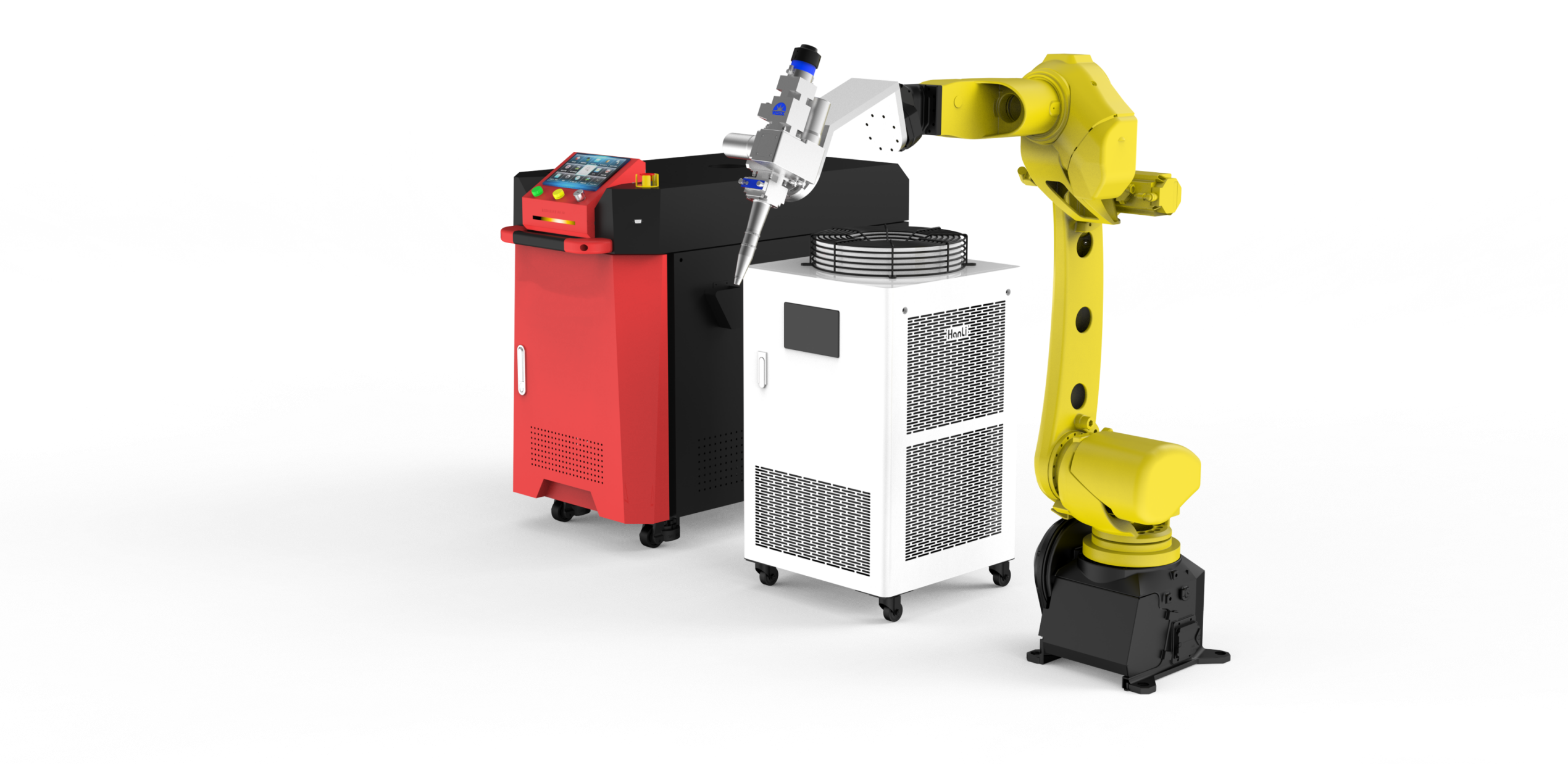

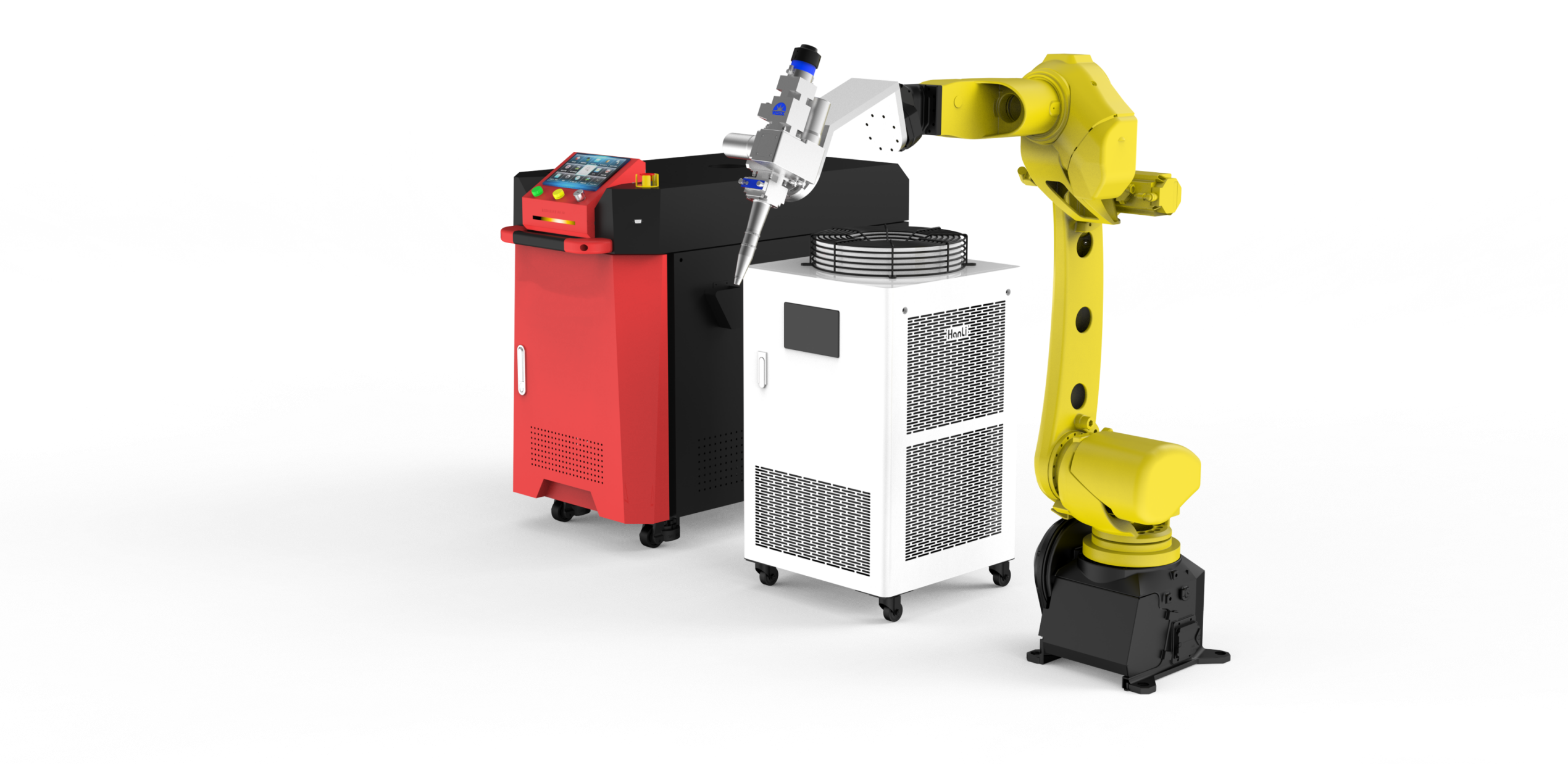

Fiber laser system robot

6 axis robot+fiber laser system The combination of a fiber laser and a 6-axis robot allows for the integration of

We use analytical cookies to improve your experience on our website

Steel channels are widely used in various applications due to their versatility, strength, and ability to support heavy loads. They come in different sizes and dimensions, and their specific designations are often standardized based on regional or international standards.

Steel channels find application in:

Structural Support: They are commonly used in building construction to support beams, columns, and other structural elements.

Framing: Steel channels are used in framing applications to create frames for walls, roofs, and floors.

Purlins and Girts: In metal building construction, steel channels can serve as purlins (horizontal supports) and girts (vertical supports) to provide structural integrity.

Machinery and Equipment: Steel channels are used in the manufacturing of machinery and equipment, providing a strong and durable framework.

Trailer and Truck Bed Rails: They are used as rails on trailers and truck beds for supporting and securing cargo.

Electrical and Plumbing Support: Steel channels can be utilized to provide support for electrical conduits, cable trays, and plumbing pipes.

CNC plasma cutting machine offers several advantages when it comes to cutting steel channels

Plasma cutting is a popular method for cutting steel, including steel channels. resulting in a clean and precise cut.

Precision: CNC plasma cutting is a highly precise process that allows for accurate cuts with minimal material waste. The computer-controlled system ensures that each cut is consistent and meets the specified design tolerances.

Speed: CNC plasma cutting machines can cut steel channels at high speeds, resulting in faster fabrication times and increased productivity. This is especially useful for large-scale projects where time is a critical factor.

Flexibility: With CNC plasma cutting, you can easily switch between different cutting patterns, designs, and material types, making it a versatile option for steel channel fabrication.

Cost-effectiveness: CNC plasma cutting is a cost-effective method of cutting steel channels because it requires minimal manual labor and material waste is kept to a minimum.

Automation: CNC plasma cutting machines are highly automated, reducing the need for manual labor and human error. This means that the fabrication process can be carried out with minimal supervision, resulting in increased efficiency and reduced labor costs.

Overall, CNC plasma cutting offers a number of advantages over traditional cutting methods, making it a popular choice for steel channel fabrication. By using this technology, manufacturers can produce high-quality, accurate, and consistent cuts in less time and at a lower cost than with traditional methods.

6 axis robot+fiber laser system The combination of a fiber laser and a 6-axis robot allows for the integration of

plasma cutting machine and laser cutting machine in beam cutting Plasma Beam Cutting Machine: A plasma beam cutting machine is a type

Auxiliary gases in laser cutting Air cutting is widely loved by laser processing customers because of its low cost, which