Menu

We use analytical cookies to improve your experience on our website

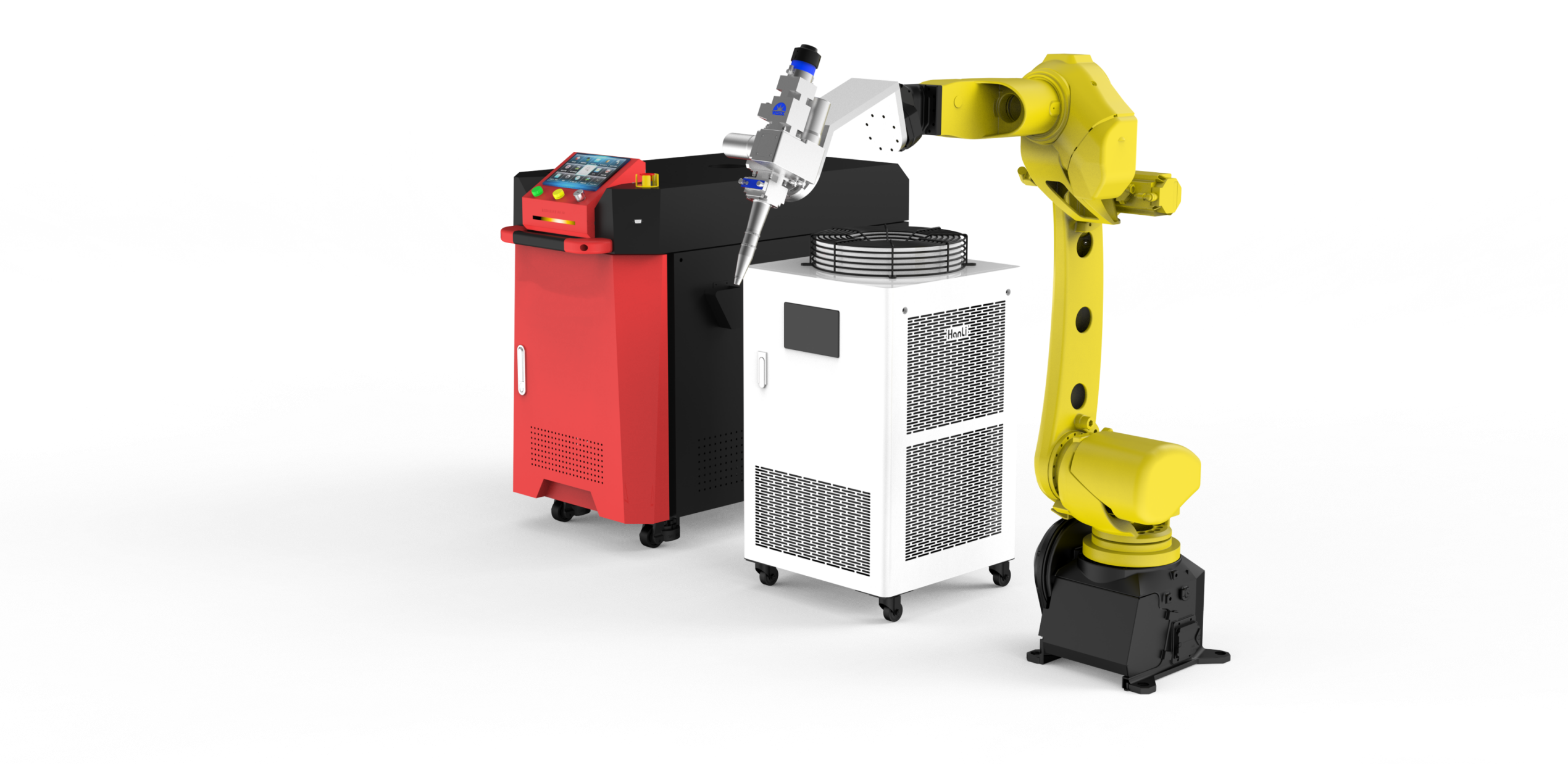

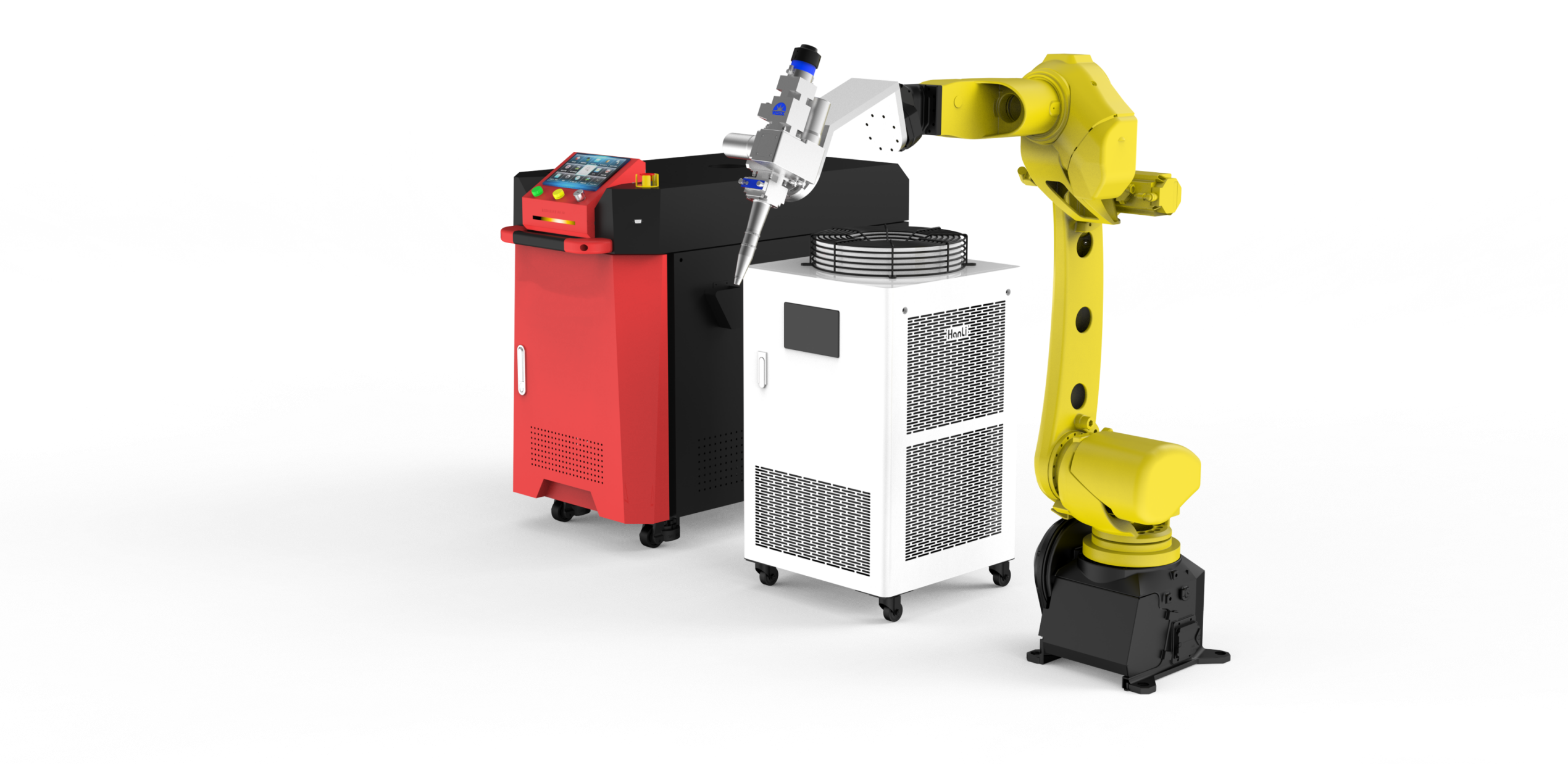

The cnc tube laser cutting machine is a type of machine tool that uses a high-powered laser to cut complex shapes and patterns into metal tubes and pipes. The laser beam is directed by mirrors to accurately cut the tube or pipe to the desired shape or pattern. Tube laser cutting machines are widely used in manufacturing industries such as automotive, aerospace, and construction for their accuracy, speed, and flexibility in cutting a wide range of materials including steel, aluminum, and titanium.

The tube laser cutting machine consists of a laser source, a control panel, and a cutting head that moves along the length of the tube or pipe. The laser beam is focused on the workpiece by a lens or a mirror, which heats the material and causes it to melt or vaporize. The cutting head moves along the length of the tube or pipe, following the programmed path, and cutting the material with high precision.

Tube laser cutting machines are used for a wide variety of applications, including cutting holes, slots, and complex shapes in tubes and pipes. They are particularly useful for cutting irregular shapes and patterns that would be difficult or impossible to achieve using traditional cutting methods. Additionally, they can cut multiple shapes in a single pass, reducing the need for multiple tool changes and improving productivity.

cnc Tube laser cutting machines are available in various sizes and configurations, depending on the type and size of the tubes or pipes being cut, as well as the production requirements of the user. Some machines are designed to handle small diameter tubes, while others are capable of cutting large diameter pipes. They can also be used to cut different shapes, including square, rectangular, and circular tubes.

When choosing a tube laser cutting machine, there are several factors you should consider to ensure you make the right decision. Here are some key points to keep in mind:

Laser Power: The laser power determines the machine’s cutting capacity and speed. Consider the thickness and type of materials you’ll be working with and choose a machine with sufficient laser power to handle those requirements.

Tube Diameter and Length: Different machines have varying maximum tube diameter and length capacities. Determine the size of tubes you’ll be working with and choose a machine that can accommodate those dimensions.

Cutting Speed and Accuracy: Look for a machine that offers high cutting speed without compromising accuracy. The machine’s positioning and motion control systems play a crucial role in achieving precise and efficient cuts.

Automation and Software: Consider the level of automation and software capabilities the machine offers. Advanced features like automatic tube loading/unloading, nesting optimization, and CAD/CAM integration can significantly enhance productivity and efficiency.

Support and Service: Research the reputation and customer support of the manufacturer or supplier. Ensure they have a good track record of providing technical support, spare parts availability, and maintenance services.

Cost and Budget: Set a budget for your tube laser cutting machine and compare different options within your price range. While it’s important to consider cost, make sure you’re also prioritizing quality and the machine’s ability to meet your specific needs.

User-Friendliness and Training: Evaluate the machine’s user interface and ease of operation. A user-friendly system will minimize the learning curve and enable your operators to quickly adapt to the machine. Additionally, check if the manufacturer offers training and resources to help your team effectively utilize the machine.

Reviews and Recommendations: Read reviews and seek recommendations from other professionals or industry experts who have experience with tube laser cutting machines. Their insights can provide valuable information about the performance, reliability, and overall satisfaction with different machine models.

Remember to thoroughly assess your requirements and evaluate multiple options before making a final decision. Consider reaching out to suppliers or manufacturers to gather more detailed information about specific models that interest you.