I believe many of you have seen various types of intelligent welding robots (or drag-and-drop robots) on Douyin. So, how exactly do these small robotic arms perform automatic welding? Today, let’s explore what a dexterous welding robot is and whether it is practical.

1. Technical Principles of Welding Robots

Laser welding robots, as part of the industrial automation field, are automated devices that use advanced computer control technology, sensor technology, and artificial intelligence technology. They can automatically complete welding tasks according to preset programs, achieving precise control over the weld.

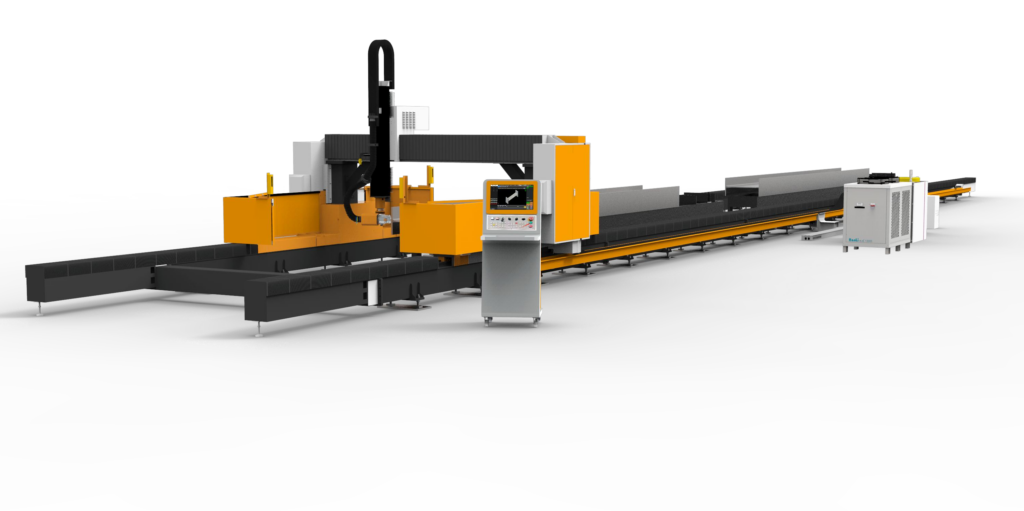

The main components of a welding robot include the robot body, the welding device, the control system, and auxiliary devices. The robot body is the core part that performs the welding tasks and can be equipped with different welding heads as needed to weld various types of workpieces. The welding device provides the welding energy, such as arc or gas, to form the weld. The control system monitors and adjusts the operation of the entire equipment, ensuring the welding process is stable and efficient. Auxiliary devices offer additional functions like safety protection and fault diagnosis to enhance the equipment’s reliability and ease of use.

2. Advantages of Welding Robots

Welding robots have many advantages, such as high efficiency, high precision, and strong stability. They can replace workers in performing long-term, high-intensity welding work, reducing labor intensity and increasing production efficiency. Additionally, intelligent welding robots ensure consistent and stable welding quality, improving the quality and reliability of products. Moreover, intelligent welding robots have high adaptability and flexibility, allowing for quick adjustments based on different workpieces and welding requirements. Their exclusive advantages include being lightweight (600mm, 20kg), portable, and providing stable welding quality.

After training, a regular operator can simultaneously operate three dexterous welding robots, saving the cost of two workers and reducing the risks associated with welding work. Welding robots increase production efficiency and product quality while lowering production costs and labor intensity.

A welding robot is a specialized type that supports integrated end-effector force control, allowing users to easily and quickly drag the welding torch to the designated start and end points. After setting the relevant welding parameters, the dexterous welding robot can begin its welding task. This type of robot learns and memorizes the welding path through the user’s real-time operations, making the teaching process more intuitive and straightforward. It eliminates the cumbersome traditional code programming and teaching pendant process, featuring a fully Chinese interface that anyone who understands Chinese can operate.

Features of Welding Robot machine:

Flexible Drag-and-Drop Teaching: Users simply drag the welding torch to the start and end points, and the robot automatically memorizes and learns the path. This teaching method is more intuitive and efficient than traditional programming.

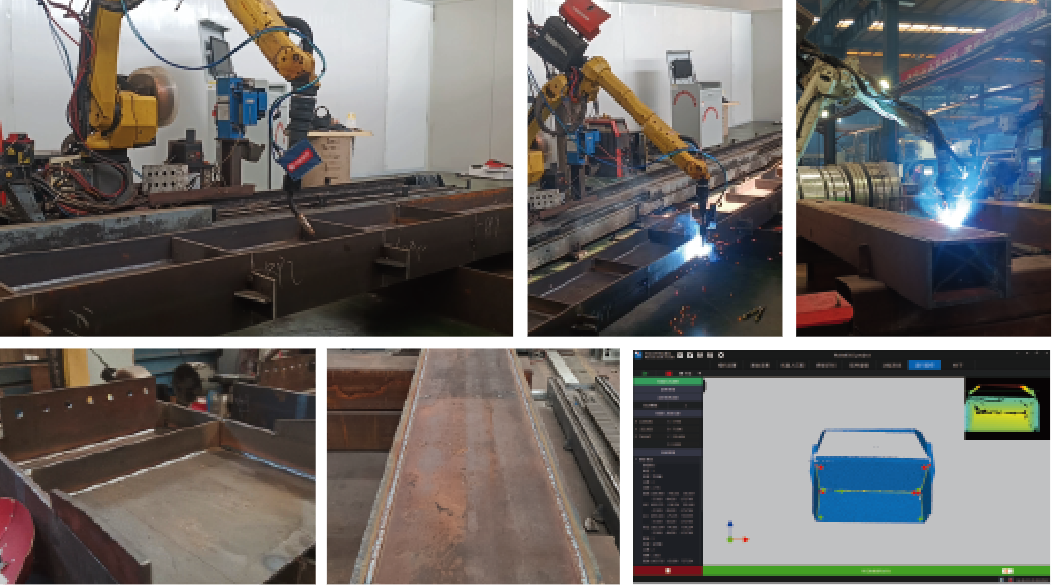

Real-Time Auto Correction: Equipped with arc tracking and laser seam tracking technology, the robot can correct welding deviations in real-time, ensuring the welding torch always stays centered on the weld seam, thereby improving welding quality.

Welding Process Package: Engineers with over 20 years of welding experience convert the skills of senior welders into general welding process parameters. The interactive design, with rich illustrations, makes welding a zero-threshold technology that anyone can master. The proprietary multi-layer multi-pass welding algorithm solves the problem of multi-layer multi-pass automatic welding, resulting in aesthetically pleasing welds.

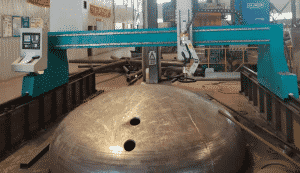

Welding robots are widely used in fields such as shipbuilding, bridge construction, and aerospace. In bridge manufacturing, welding robots can quickly and accurately complete tasks like diaphragm welding and steel anchor beam welding, significantly improving production efficiency and quality. In shipbuilding, welding robots can handle welding of complex workpieces like lattice structures and box girders, ensuring consistency and reliability of structural welding, and reducing production cycles.