Top 5 Welding Robots with 2m Arm Reach for MAG Welding in 2025

Introduction

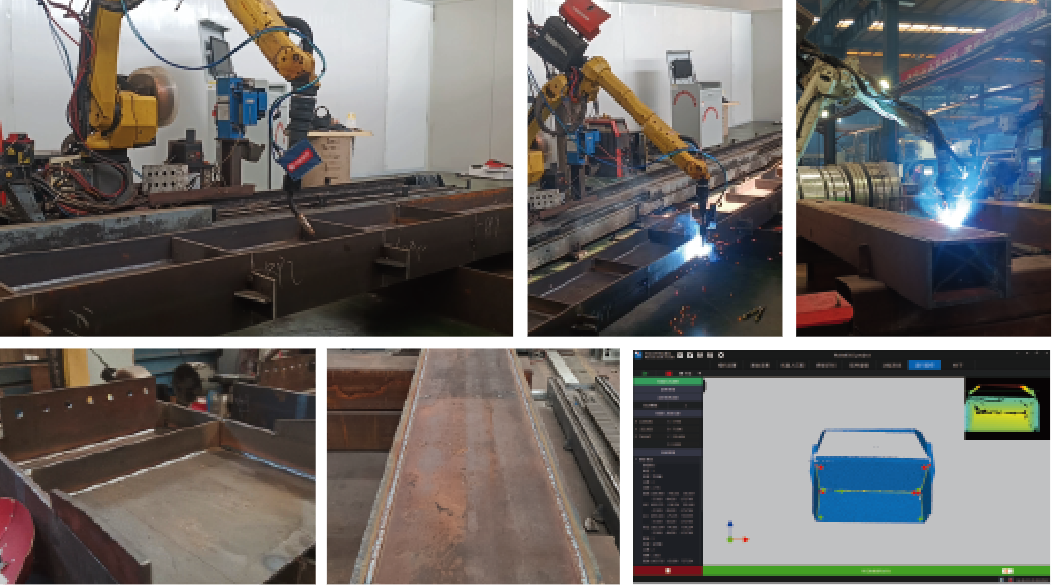

In 2025, MAG (Metal Active Gas) welding robots with approximately 2m arm reach dominate mid-scale fabrication, offering precision for steel and aluminum structures in automotive, shipbuilding, and general manufacturing. These 6-axis arms support high-deposition MIG variants, reducing spatter and heat input for cleaner welds. Selection criteria include reach (1.8-2.2m), payload (5-20kg), speed, integration with power sources like Fronius TPSi, and ROI via 20-30% labor savings. Prices cover arm + basic cell;. This top 5 prioritizes reliability, seam tracking, and value.

1. Yaskawa AR2010

- Reach: 2009 mm

- Payload: 10 kg

- Key Tech: WeldPRO software for offline programming, integrated seam finder with laser sensor, MotoSim VR simulation, EtherCAT for real-time control, IP67 protection. Supports MAG with up to 350A current, low-spatter arc control.

- Speed: 2.2 m/s max axis, 25 m/min wire feed.

- Price: $80K–$120K

- Strength: Exceptional path accuracy (±0.07 mm repeatability); 25% faster cycle times on 3-10mm plates via adaptive weaving. Ideal for automotive frames.

- Weakness: Requires skilled setup for custom fixtures.

The AR2010 excels in dynamic MAG welding, handling complex geometries with minimal downtime. Its hollow arm reduces cable wear, boosting uptime to 99% in continuous runs.

2. KUKA KR CYBERTECH ARC 10 R1400

- Reach: 2100 mm

- Payload: 10-16 kg

- Key Tech: KRC5 controller with ArcTech package, through-the-arm torch cabling, Ready2_Arc for plug-and-weld setup, 3D vision for gap detection, ISO 10218 safety. Optimized for MAG with cold metal transfer (CMT) options.

- Speed: 2 m/s, 20 m/min wire speed.

- Price: $90K–$140K

- Strength: Streamlined design cuts interference by 40%; superior for large panels up to 15mm thick, with 15% less consumable use.

- Weakness: Higher initial calibration time in multi-robot cells.

KUKA’s model shines in heavy fab shops, where its extended reach accesses awkward joints without repositioning. AI-driven error correction minimizes rework.

3. ABB IRB 2600

- Reach: 1850 mm

- Payload: 5-20 kg (configurable)

- Key Tech: RobotStudio for virtual commissioning, LeanArc torch for reduced spatter, SafeMove2 collaborative safety, OmniCore controller with fieldbus integration. MAG-ready with pulse arc for thin sheets.

- Speed: 2.2 m/s, 30 m/min feed rate.

- Price: $70K–$110K

- Strength: Versatile payload scaling; 30% energy savings on long runs, excels in aluminum MAG with minimal distortion.

- Weakness: Software ecosystem pricier for advanced add-ons.

ABB’s IRB 2600 is a workhorse for mixed-material welding, integrating seamlessly with ERP systems for Industry 4.0 traceability.

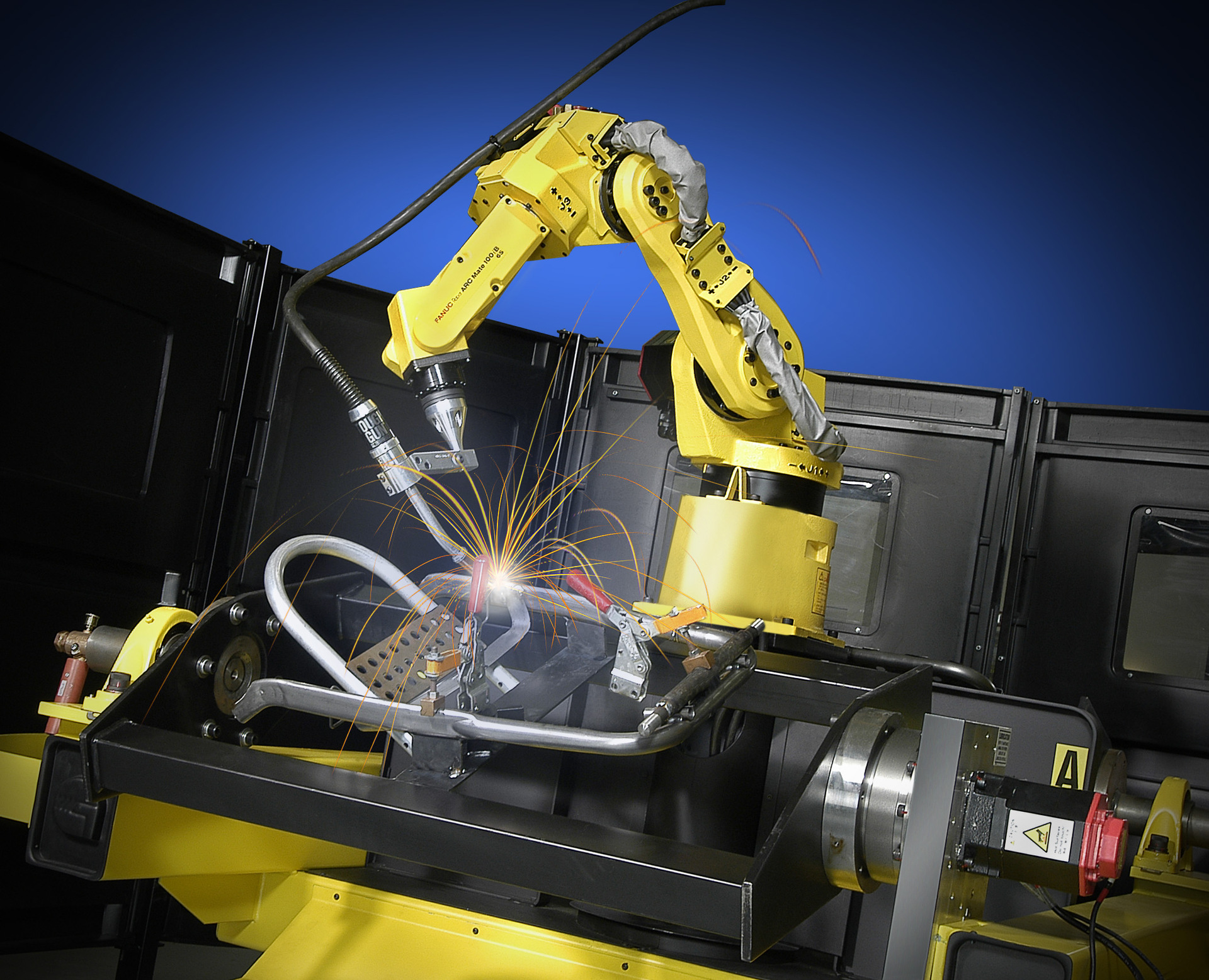

4. FANUC M-20iD/25

- Reach: 1831 mm

- Payload: 25 kg

- Key Tech: R-30iB Plus controller, ArcTool with touch sensing, iRVision for bin picking/welding, slim arm for tight access, ULPA filtration for clean environments. Full MAG support with high-duty torches.

- Speed: 2.5 m/s max, 28 m/min wire.

- Price: $75K–$115K

- Strength: Highest payload in class for fixtures; 20% faster piercing on galvanized steel, robust for 24/7 ops.

- Weakness: Bulkier base limits floor space in small bays.

FANUC’s offering prioritizes durability, with proven 50,000+ hour MTBF in MAG-intensive lines like trailer manufacturing.

5. Panasonic TM-2000A (TAWERS Series)

- Reach: 2000 mm

- Payload: 8 kg

- Key Tech: iWeld remote teaching, SuperActive Wire Process for stable arcs, integrated positioner control, lightweight aluminum arm, CE/UL certified. Tailored for MAG with auto-gas mixing.

- Speed: 2 m/s, 22 m/min feed.

- Price: $65K–$100K

- Strength: Easiest remote programming via tablet; 35% lower spatter on carbon steel, cost-effective for SMEs.

- Weakness: Limited third-party tool ecosystem compared to Big Four.

Panasonic’s TM-2000A democratizes MAG automation, with intuitive interfaces slashing training to under 2 hours.

Comparison Table

| Rank | Model | Reach (mm) | Payload (kg) | Price Range | Key Edge |

|---|---|---|---|---|---|

| 1 | Yaskawa AR2010 | 2009 | 10 | $80K–$120K | Path accuracy & speed |

| 2 | KUKA KR CYBERTECH ARC | 2100 | 10-16 | $90K–$140K | Interference-free design |

| 3 | ABB IRB 2600 | 1850 | 5-20 | $70K–$110K | Payload versatility |

| 4 | FANUC M-20iD/25 | 1831 | 25 | $75K–$115K | Durability & payload |

| 5 | Panasonic TM-2000A | 2000 | 8 | $65K–$100K | User-friendly programming |

Trends in 2025

Per SwitchWeld and Qviro reports, AI seam tracking now standard, cutting defects by 40%. Hybrid cobot-industrial setups rise 25%, but pure industrial arms like these lead for MAG due to power handling (up to 500A). Integration costs: $15K–$40K for vision/power sources. Market growth: 12% YoY, driven by EV battery trays. Sustainability focus: Low-spatter processes reduce CO2 by 15%.

Selection Guide

- Precision automotive: Yaskawa AR2010.

- Large structures: KUKA KR CYBERTECH.

- Mixed payloads: ABB IRB 2600.

- High-volume endurance: FANUC M-20iD.

- Budget entry: Panasonic TM-2000A. Consider site audits for reach verification; all comply with ISO 10218-1 for safe MAG ops.

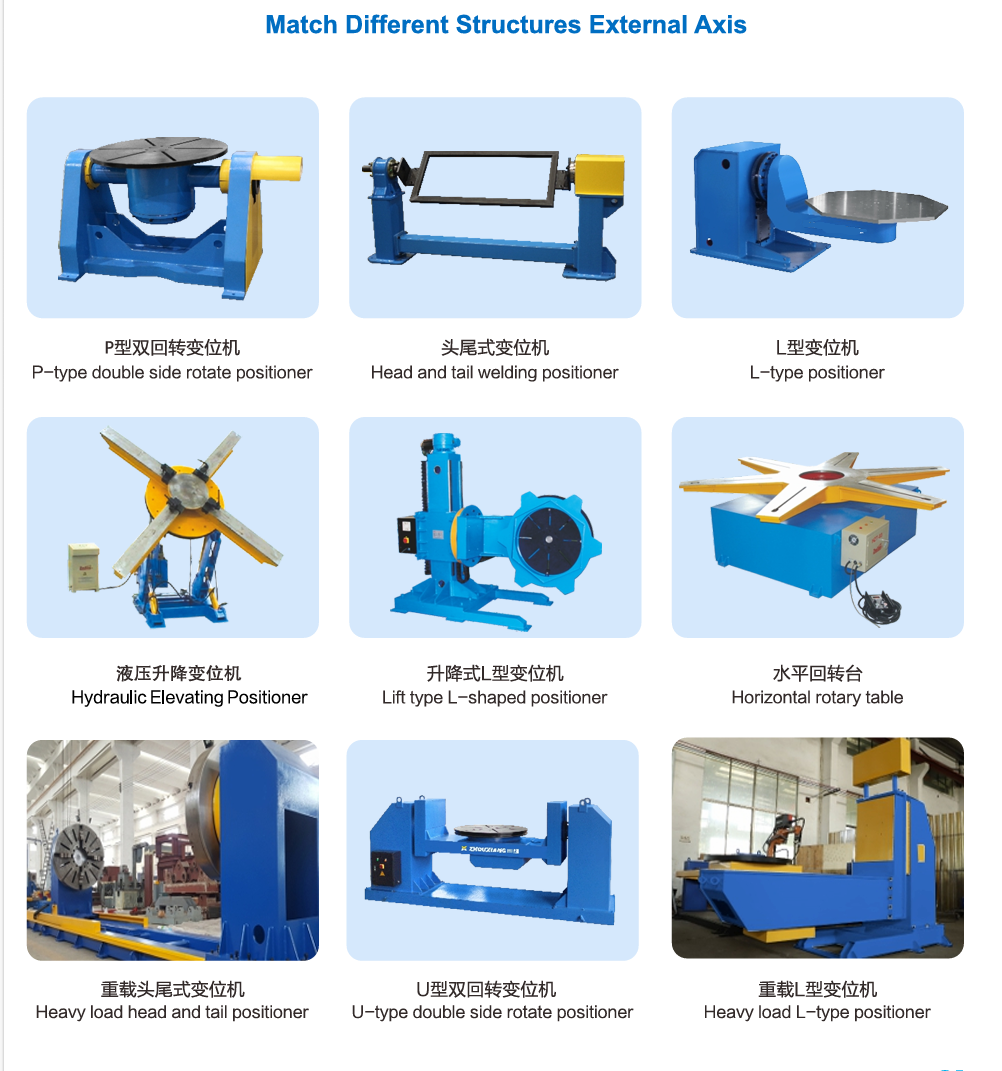

We are robot integrators and can provide robot welding machines from the four major families.

whatsapp: +8618660174681