Robot aluminum tube welding for door and window manufacturing can provide several benefits, including increased efficiency, precision, and consistency in the welding process.

Aluminum is a popular material for door and window frames due to its strength, durability, and resistance to corrosion. Welding aluminum can be challenging because it has a relatively low melting point and is highly conductive, which makes it challenging to maintain the necessary heat during welding.

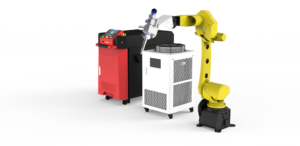

Robotic welding machine can help overcome these challenges by providing a consistent heat source and precise control over the welding process. With robotic welding, a computer program controls the welding process, ensuring consistent weld quality and reducing the likelihood of defects. Additionally, robots can weld at a much faster pace than human welders, increasing production efficiency and reducing the time it takes to manufacture each frame.

Overall, robot aluminum tube welding can provide significant benefits for door and window manufacturing, including improved quality, consistency, and efficiency. It’s worth considering for any manufacturer looking to streamline their production process and improve their bottom line.

There are several advantages of using robot welding machine for door and window

Consistency: Robots are programmed to perform welding tasks with a high degree of precision and consistency, ensuring that each weld is the same as the last. This consistency is crucial for producing high-quality products that meet industry standards.

Efficiency: Robots are faster than human welders and can work around the clock without getting tired or needing breaks. This means that they can produce more products in less time, increasing production efficiency and reducing costs.

Accuracy: Robots can perform welding tasks with a high degree of accuracy, ensuring that each weld is placed exactly where it needs to be. This is especially important for door and window frames, which need to be precise to ensure a good fit and proper functionality.

Safety: Welding can be a dangerous task, with risks including burns, fumes, and electrical shock. By using robots, manufacturers can keep their workers safe by removing them from potentially hazardous environments.

Flexibility: Robots can be programmed to perform a wide range of welding tasks, making them highly versatile. This means that they can be used for different types of door and window frames and can adapt to changes in production requirements.

Overall, the use of robots in door and window welding can improve quality, increase efficiency, and enhance safety in the manufacturing process. These advantages make robot welding an attractive option for manufacturers looking to optimize their production processes and improve their bottom line.