1. Introduction

With the rapid advancement of technology, automation has become a key technology in various fields. In manufacturing, welding automation technology is an important means to improve production efficiency and reduce costs. This article will explore the current status and development trends of welding automation technology in China.

2. Development of Welding Automation Equipment in China

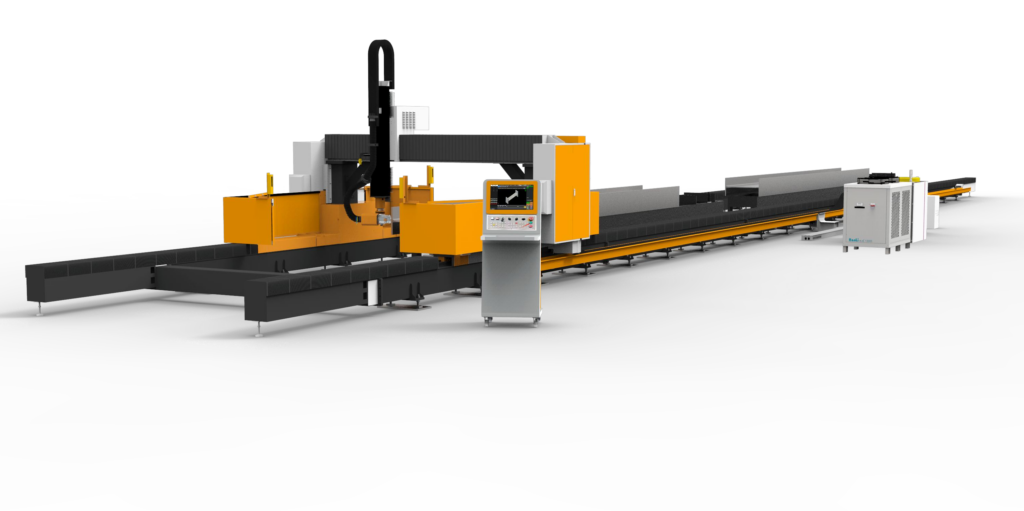

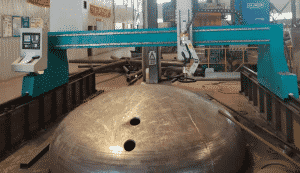

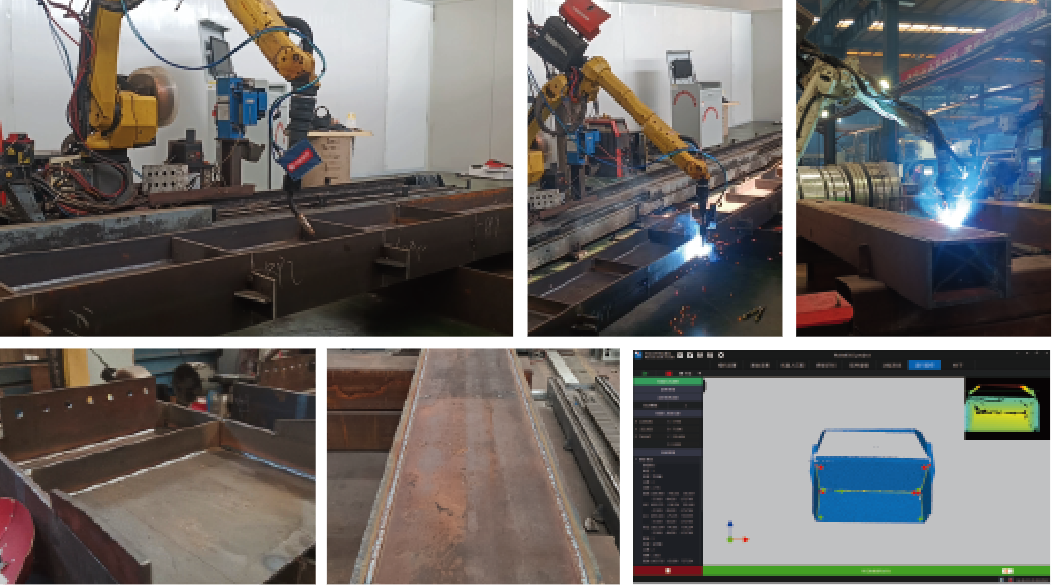

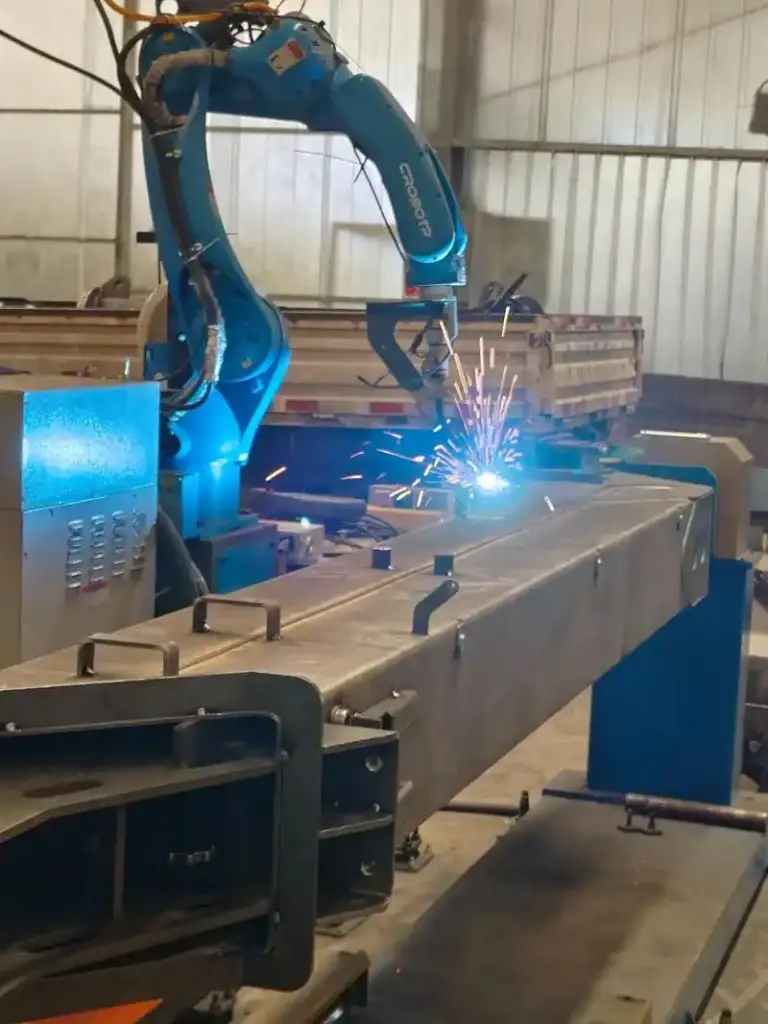

In recent years, welding automation equipment in China has developed rapidly. Robotic welding has become mainstream, with automated welding machines, laser welding machines, plasma welding machines, and other automated equipment being widely applied in production. These devices feature high efficiency, high precision, and high stability, greatly improving production efficiency and quality.

3. Intelligent Development

With the advancement of artificial intelligence and machine learning technologies, intelligence has become an important direction for the development of welding automation technology. Intelligent welding systems can monitor and adjust the welding process in real-time through sensors and algorithms, improving welding quality and efficiency. China has achieved certain results in intelligent welding technology, but further research and innovation are needed.

4. High-Speed and High-Efficiency Development

High-speed and high-efficiency are other important trends in welding automation technology. By optimizing welding processes and improving equipment performance, fast and efficient welding production can be achieved, significantly increasing production efficiency and reducing costs. Research in high-speed and high-efficiency welding in China is still in the early stages, but with continuous technological progress, more results are expected in the future.

5. Optimization of Welding Processes

Optimizing welding processes is a crucial link in improving welding automation technology. Through methods such as experiments and simulations, optimizing welding process parameters can improve welding quality and efficiency. China has made certain achievements in welding process optimization, but further research and application are needed.

6. Remote Control and Unmanned Technology

With the development of industrial internet technology, remote control and unmanned technology have become future trends in welding automation. By utilizing internet technology, remote monitoring and control of welding equipment can be achieved, improving equipment reliability and safety. Research in remote control and unmanned technology is still in the early stages in China, but with continuous technological advancements, more results are expected in the future.

7. Conclusion

China has made significant progress in welding automation technology, particularly in equipment development, intelligence, high-speed and high-efficiency processes, process optimization, and remote control and unmanned technology. However, in the face of the rapidly developing technological and economic environment, further research and innovation are needed to promote the development and application of welding automation technology in China.