Plasma Cutting Technology in Metal Sheet Processing

1. Limitations of Traditional Cutting Methods

Traditional metal sheet cutting processes have certain limitations, primarily due to the complexity of operations and significant safety hazards. These challenges create constraints in industrial production. However, by improving existing methods, not only has cutting efficiency increased, but the process has also become more flexible.

2. Advantages of Plasma Cutting

In conventional machining and repair industries, steel cutting was typically performed using grinding wheel cutters for wires and oxy-acetylene gas cutting for sheets. However, oxy-acetylene gas cutting is inconvenient, inefficient, and poses considerable safety risks, limiting its use in industrial production.

Today, plasma cutting has been widely adopted in industrial production and general repair industries for processing most steel sheet materials. Plasma cutting uses a plasma arc at extremely high temperatures to locally melt the material. The working gas, heated by the plasma arc in the nozzle of the plasma torch, rapidly expands and is ejected at high speed, blowing away the molten metal and forming a narrow cut in the material.

In terms of material compatibility, cutting thickness, and cutting quality, plasma arc cutting is currently one of the best cutting methods available. It can be summarized by three key characteristics: high speed, high efficiency, and high quality.

3. Characteristics of Plasma Cutting

During the actual cutting process, operators must be well-versed in the operation of plasma cutting equipment. Selecting the appropriate working gas is crucial, as different gases have distinct properties during cutting. Commonly used gas mixtures include nitrogen and hydrogen, typically composed of 75%-90% nitrogen and 10%-25% hydrogen. For cutting materials over 127 mm thick, such as stainless steel and specific stainless steel alloys, pure argon can also be used.

To ensure adjustable plasma arc cutting, selecting the correct arc current and voltage is essential. Increasing arc current and voltage enhances the power of the arc, but excessive current can accelerate wear on tungsten plates and nozzles, negatively impacting cutting performance. Therefore, increasing arc voltage is the preferred method for boosting power. Additionally, increasing the flow rate of the gas mixture compresses the arc further, concentrating energy and raising arc temperature. This increases arc jet speed and cutting power, which improves cutting speed.

Other key factors affecting cutting quality include the nozzle length and diameter, the distance between the nozzle and the workpiece, and the tungsten electrode’s alignment. In some cases, excessive cutting burrs can occur due to poor molten metal flow, insufficient gas flow, or excessive heat at the bottom of the cut. In thick plate cutting, larger kerf width can also lead to excessive drag, causing additional burr formation. To prevent these issues, it is crucial to maintain precise tungsten electrode and nozzle alignment, ensure adequate power, and optimize gas flow and cutting speed.

For small and medium-sized machining and repair enterprises, low-current plasma cutting is a significant advancement. It features low gas consumption, reduced maintenance and equipment costs, minimal smoke and noise, simple structure, and easy operation.

Typical applications of low-current plasma cutting include:

4. Types and Applications of Plasma Cutting Equipment

4.1 Types of Plasma Cutting Equipment

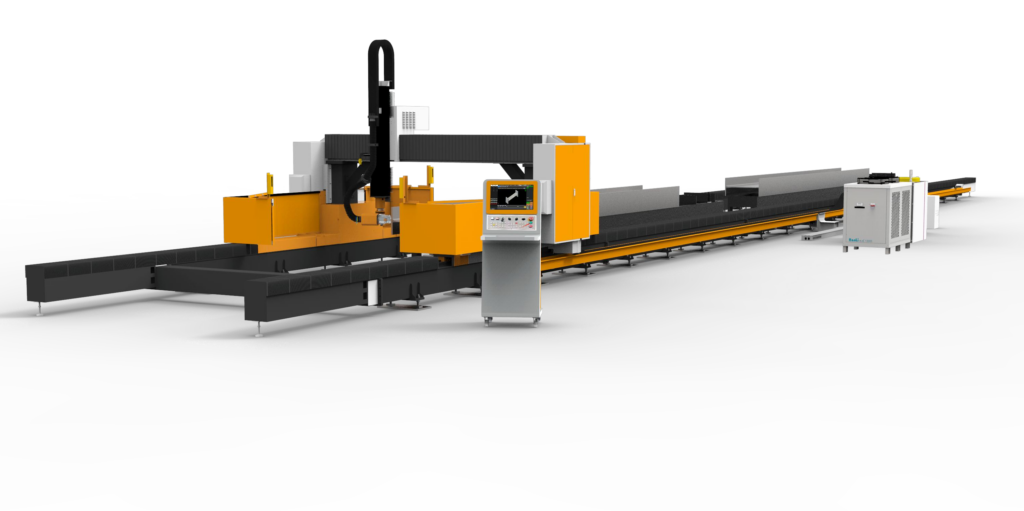

Among various plasma cutting technologies, CNC plasma cutting is the most widely used today. CNC plasma cutting equipment consists of three main components:

- Machine Tool Section: Includes the reducer, guide rails, and servo motors.

- CNC Control System: Consists of a computer, gas circuit system, and auxiliary electromechanical equipment.

- Programming Software: Handles the software operations for plasma cutting terminals.

Modern plasma cutting machines use non-high-frequency arc ignition technology, where a high-pressure gas flow between the power electrode and the nozzle generates a pilot arc that ignites the plasma. This method eliminates the need for high-frequency oscillators, which can create strong electromagnetic fields (130-210 kHz) that interfere with surrounding high-voltage equipment. To counteract this, specialized control mechanisms are built into the system to ensure accurate arc ignition.

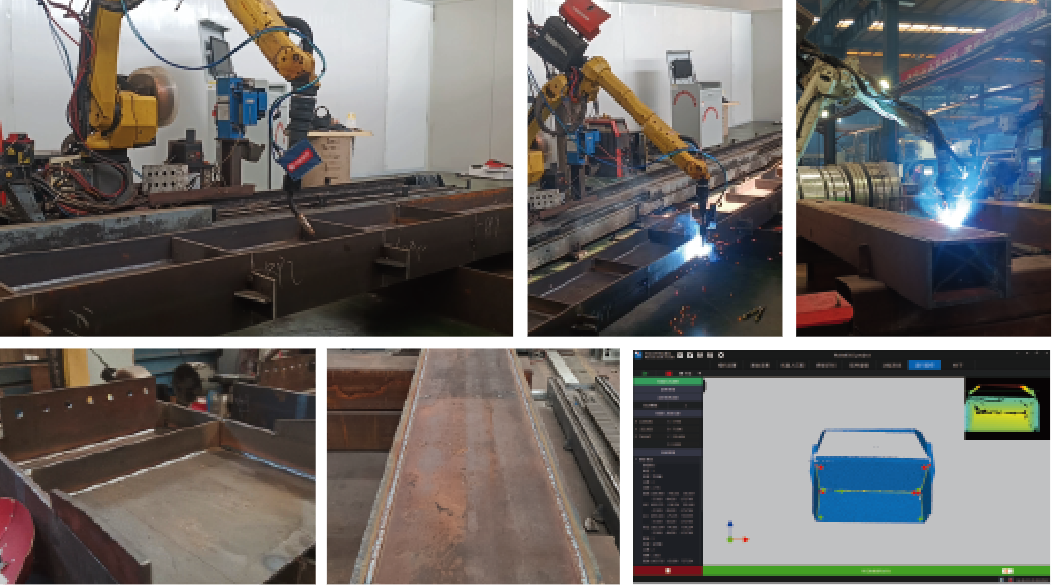

4.2 Application of Plasma Cutting in Steel Structure Production

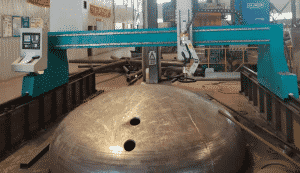

During CNC plasma cutting, steel structures are drawn and programmed before being transferred as DXF files to a terminal server, ensuring seamless data exchange. The cutting head follows the programmed trajectory while maintaining a cutting temperature between 4,500-5,000°C. At this temperature, intense atomic collisions within the steel structure cause electron separation, creating a high-energy ionized state that facilitates efficient steel cutting.

CNC plasma cutting ensures smooth transitions between right angles, unlike traditional plasma cutting, which often struggles to achieve smooth curves, leading to large uncut areas. The cutting software in CNC plasma machines ensures precise angular adjustments, optimizing the cutting process.

5. Conclusion

Through the analysis of plasma cutting in industrial applications, it is evident that this technology offers significant improvements over traditional cutting methods. Plasma cutting not only optimizes the cutting process but also simplifies operations and enhances production efficiency. This innovative cutting technology will continue to drive economic benefits for various industries, contributing to higher national productivity in the future.