Robot Laser Welding Machine: Enhancing Welding Quality and Expanding Applications

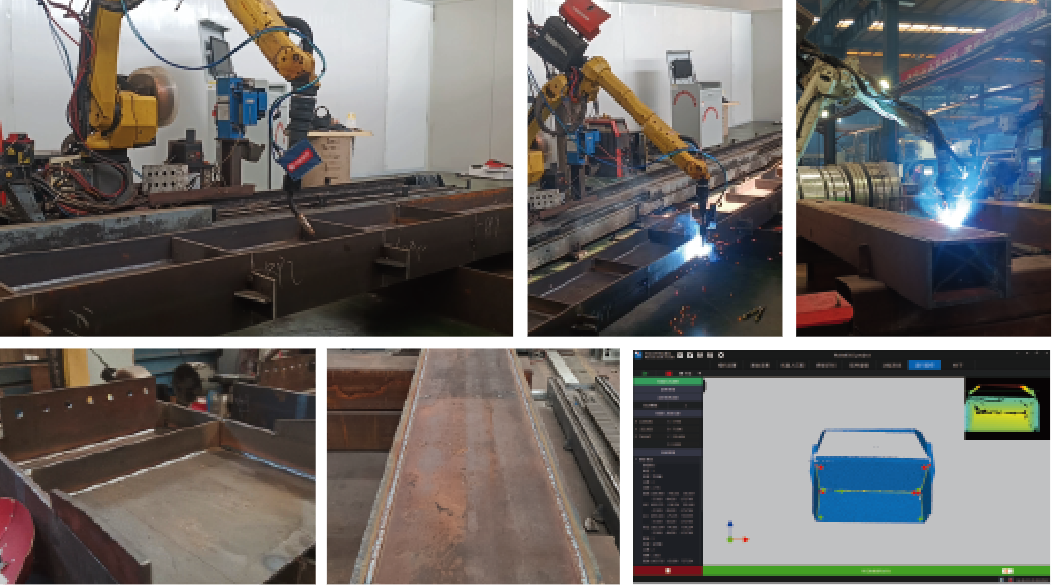

The robot laser welding machine effectively improves welding quality and is increasingly being adopted across various industries. It is widely used for welding applications such as automobile chassis, seat frames, mufflers, guide rails, and hydraulic torque converters. Its adoption significantly enhances work efficiency.

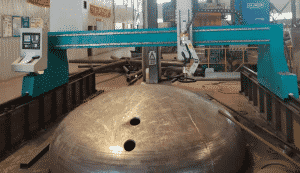

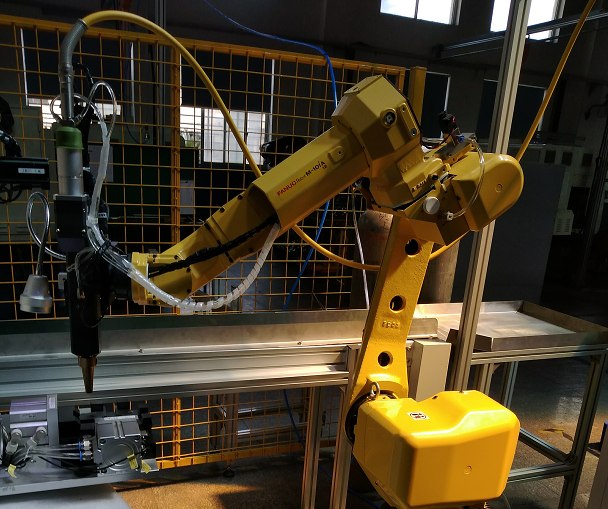

On-Site Robot Laser Welding

Why is the application of robot laser welding machines becoming more widespread? Let’s explore its components, working principles, and advantages.

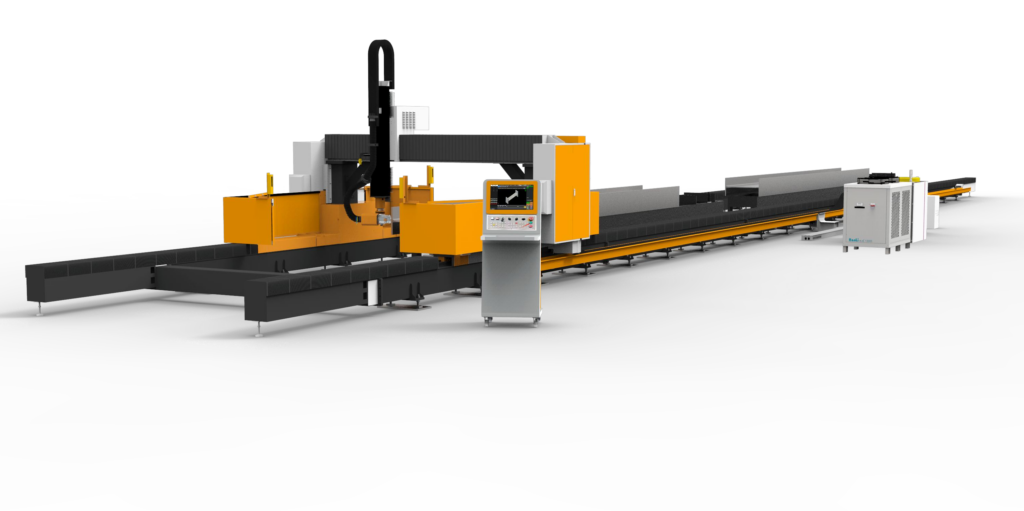

Components of a Robot Laser Welding Machine

- Robot Body

The robot body is typically a six-axis articulated manipulator driven by a servo motor. It consists of a drive unit, transmission mechanism, robotic arm, joints, and internal sensors. Its primary function is to precisely control the position, posture, and movement trajectory of the welding gun at the end of the robotic arm. - Robot Control Cabinet

Acting as the central nervous system of the robot, the control cabinet includes computer hardware, software, and specialized circuits. It processes all operational data and controls the robot’s movements during welding. - Welding Power System

This includes the welding power supply and a specialized welding gun to deliver precise and consistent welding results. - Welding Sensors and Safety Protection System

These components ensure precise operation and maintain workplace safety. - Welding Fixtures

Automated clamping fixtures are designed to securely hold and position workpieces during welding.

Working Principle of Robot Laser Welding

The welding robot is programmed by manually guiding it through the welding process step by step. During this process, the robot memorizes the taught positions, postures, movement parameters, and welding settings. It then automatically generates a continuous program to execute the entire welding operation.

Advantages of Robot Laser Welding Machines

Compared to traditional laser welding machines, robot laser welding machines offer the following benefits:

- Enhanced and Stable Welding Quality

Welding quality can be precisely quantified and controlled, ensuring consistency. - Increased Productivity

The automation of the process significantly boosts efficiency. - Reduced Labor Intensity

Operators are relieved from physically demanding tasks, improving workplace conditions. - Lower Skill Requirements for Operators

Unlike manual welding, robotic welding reduces the need for highly skilled labor. - Shorter Product Development and Upgrade Cycles

Automated welding reduces setup times, making it easier to adapt to product changes while minimizing equipment investment.

Robot Laser Welding in Action

With these clear advantages, robot laser welding machines are set to play an increasingly important role in the welding industry.