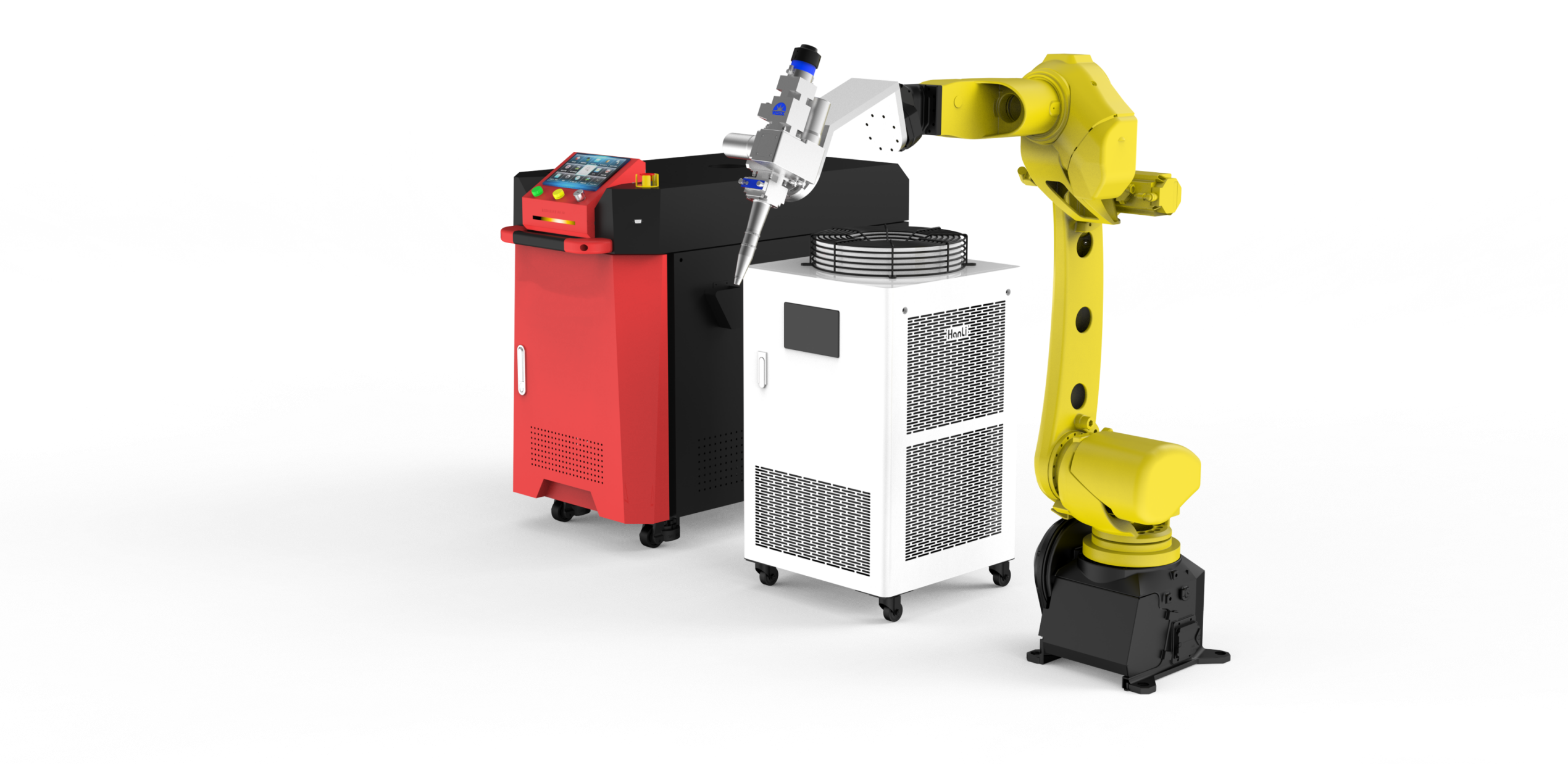

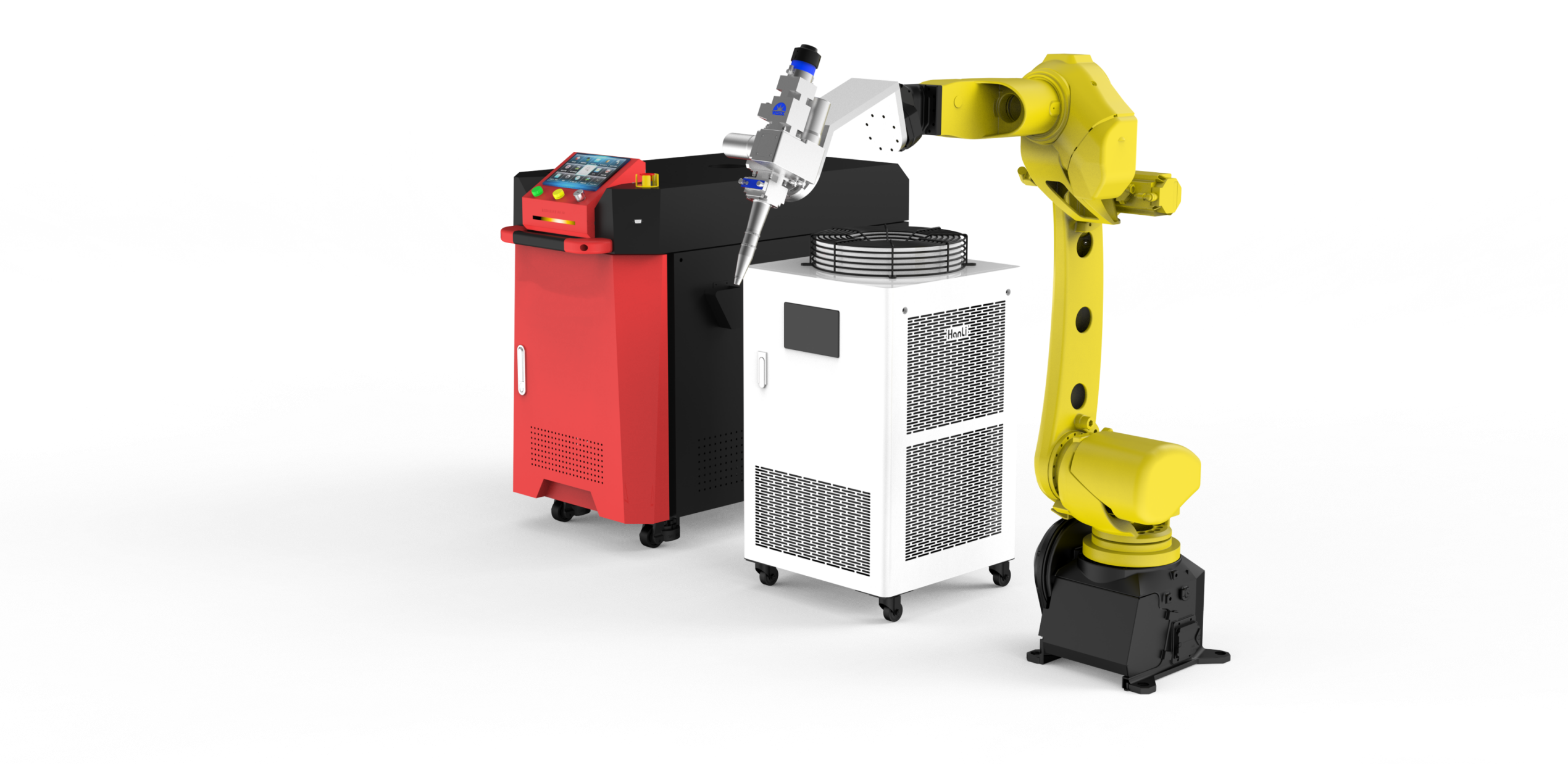

Fiber laser system robot

6 axis robot+fiber laser system The combination of a fiber laser and a 6-axis robot allows for the integration of

We use analytical cookies to improve your experience on our website

The cnc stainless laser cutting machine is a type of laser cutting machine that is designed specifically for cutting stainless steel material. These machines use a focused laser beam to cut through the stainless steel material, producing clean and precise cuts.

Stainless laser cutting machines come in various sizes and power capacities, depending on the specific needs of the user. They are used in a variety of industries, including automotive, aerospace, medical, and architectural, to cut stainless steel components for various applications.

One of the advantages of using a stainless laser cutting machine is its ability to produce precise cuts with minimal material waste. It can also cut complex shapes and designs quickly and accurately, reducing the need for secondary operations such as grinding or finishing.

When choosing a stainless laser cutting machine, it is important to consider factors such as power capacity, cutting speed, cutting thickness, and the type of stainless steel material that will be cut. It is also important to ensure that the machine is maintained properly and operated safely to ensure optimal performance and longevity.

There are several reasons why laser cutting machines are a popular choice for cutting stainless steel:

Precision: Laser cutting machines offer a high level of precision and accuracy. They are capable of cutting intricate and complex designs with ease, producing clean and precise cuts that require minimal post-processing.

Speed: Laser cutting machines are faster than traditional cutting methods, such as sawing or shearing. They can cut through thick stainless steel material quickly, reducing production time and increasing productivity.

Versatility: Laser cutting machines can cut a variety of materials, including stainless steel, aluminum, and other metals. They can also cut different thicknesses and densities of materials, making them a versatile option for a wide range of applications.

Minimal Material Waste: Laser cutting machines have a narrow kerf (cutting width), which means they produce minimal material waste. This can help reduce the cost of materials and improve the efficiency of the cutting process.

Automation: Laser cutting machines can be programmed to perform automated cutting processes, reducing the need for manual labor and increasing productivity. This also helps ensure consistency and accuracy in the cutting process.

Overall, laser cutting machines are a reliable and efficient option for cutting stainless steel. They offer precision, speed, versatility, and automation, making them a popular choice in a variety of industries.

6 axis robot+fiber laser system The combination of a fiber laser and a 6-axis robot allows for the integration of

plasma cutting machine and laser cutting machine in beam cutting Plasma Beam Cutting Machine: A plasma beam cutting machine is a type

Auxiliary gases in laser cutting Air cutting is widely loved by laser processing customers because of its low cost, which