12kW H-Beam Laser Cutting Machine Infinite Rotation 3D Head for Bridge Engineering in Katowice

Field Eval: 12kW H-Beam Laser integration in Katowice bridge works. Infinite 3D Head optimizes V/K-bevels, reducing HAZ and eliminating secondary milling.

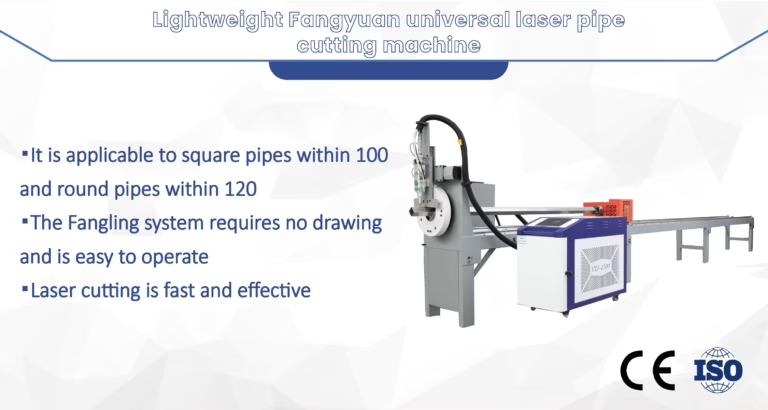

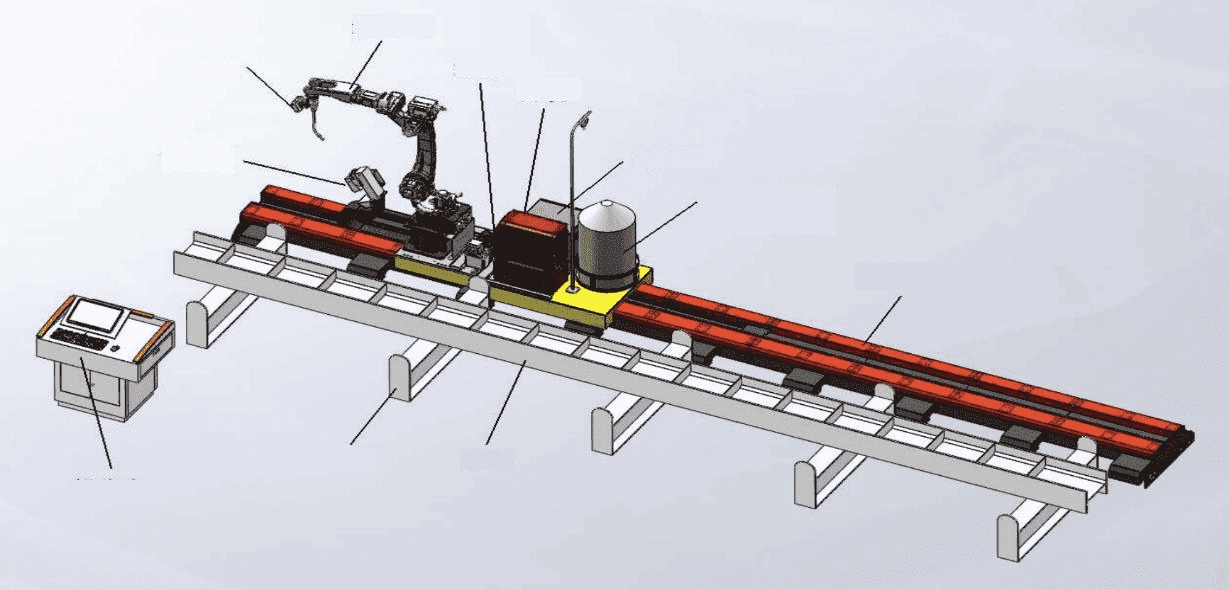

In the metal fabrication industry, having the right tools and equipment is crucial for ensuring efficient and accurate work. One such tool is the pipe profile cutting machine. This machine is used for cutting pipes and profiles made of different materials, including steel, aluminum, and plastic. The machine can perform various cutting techniques such as plasma cutting, laser cutting, and water jet cutting.

Plasma Cutting

Plasma cutting is a popular cutting technique used in the metal fabrication industry. It uses a high-speed stream of ionized gas to cut through metal, creating a precise and clean cut. This technique is ideal for cutting thicker pipes and profiles as it can handle materials up to 100mm thick.

Laser cutting is another cutting technique used in pipe profile cutting machines. This method uses a focused laser beam to cut through metal. The laser beam is controlled by a computer, allowing for precise and accurate cuts. Laser cutting is ideal for cutting thin pipes and profiles as it can handle materials as thin as 0.1mm.

Water Jet Cutting

Water jet cutting is a cutting technique that uses a high-pressure stream of water to cut through metal. This method is ideal for cutting materials that are sensitive to heat, as there is no heat generated during the cutting process. Water jet cutting is also ideal for cutting complex shapes as it can be controlled by a computer for precise cuts.

Accuracy: Pipe profile cutting machines allow for precise and accurate cuts, reducing the need for additional finishing work.

Speed: The machines can cut through metal quickly, reducing the time required for cutting and increasing overall production efficiency.

Versatility: Pipe profile cutting machines can be used for cutting a variety of materials, making them a versatile tool for metal fabrication.

Cost-effective: The machines can reduce the cost of cutting by reducing the amount of waste generated during the cutting process.

Conclusion

Pipe profile cutting machines are essential tools for the metal fabrication industry. They provide precise and accurate cuts, increase production efficiency, and are cost-effective. Whether you are working with plasma, laser, or water jet cutting, these machines are an investment that will pay off in increased productivity and improved quality of your work

Field Eval: 12kW H-Beam Laser integration in Katowice bridge works. Infinite 3D Head optimizes V/K-bevels, reducing HAZ and eliminating secondary milling.

Precision Engineering: The 2kW Sheet Metal laser cutting Guide for Aluminum Alloys in Monterrey Monterrey, Nuevo León, has long been established as the industrial heart

The integration of 6000W CNC fiber laser technology with infinite rotation 3D cutting heads represents a paradigm shift for Dubai’s burgeoning railway sector. As the UAE expands its national rail network and enhances urban transit systems, the demand for precision-engineered structural steel—specifically H-beams, I-beams, and channels—has reached an all-time high. This expert analysis explores how 6000W of fiber laser power, combined with five-axis cinematic freedom, overcomes the environmental challenges of the Middle East while delivering the structural integrity required for high-speed rail infrastructure.

Fill out the form below, and we will be in touch shortly.