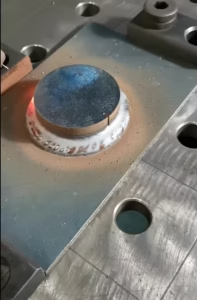

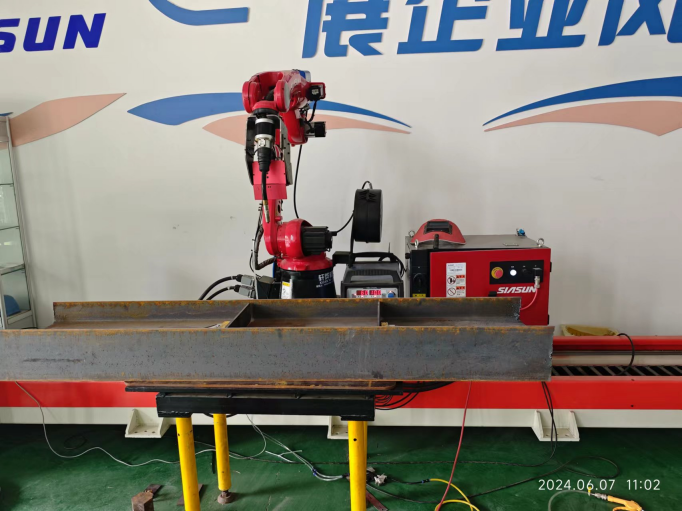

MIG (melting inert gas) welding is known for its efficient and powerful welding capabilities. Combined with robotics, this new machine automates the welding process, dramatically increasing productivity and reducing errors in manual operations.The MIG robotic welding machine is not only capable of handling complex welding tasks, but also has the ability to handle a wide range of applications in a variety of fields, including automotive manufacturing, shipbuilding, construction engineering and heavy machinery manufacturing.

Why choose MIG robot welding machine?

High precision and consistency: state-of-the-art sensors and control technology are used to ensure quality and consistency in every weld.

Improved productivity: Automated welding reduces manual intervention and significantly improves the operational efficiency of the production line.

Versatility: Suitable for a wide range of metal materials and complex shapes to meet the needs of different industries.

Cost savings: Despite the high initial investment, automated welding significantly reduces labor costs and material waste in the long run.

Safety: Reduces the amount of time workers are exposed to high temperatures and pressurized environments, dramatically improving safety in the workplace.

Industry Reaction

Industry experts have applauded the launch of the MIG robotic welding machine, saying it will be a major leap forward in the field of welding technology. “The launch of this machine marks a new era in the welding industry. It not only improves productivity, but also enhances product quality, meeting the dual demands of modern manufacturing for high precision and high efficiency.” Mr.aid said.

Customer Feedback

Prior to its release, the MIG robotic welder was tested at a number of leading manufacturing companies, and the results showed that it performed well beyond expectations. The production manager of an automotive manufacturing company said, “Since introducing this machine, our production line efficiency has increased by 30% and weld quality is more consistent. It is definitely a great asset to our company.”

ShanDong PCL has always been committed to providing state-of-the-art manufacturing solutions to customers around the world. With years of industry experience and technology accumulation, we continue to innovate and are committed to advancing manufacturing technology and helping our customers achieve their goals of more efficient and environmentally friendly production.

The introduction of the MIG Robotic Welder is undoubtedly a revolutionary advancement in the welding industry. We expect that this innovative product will help more companies to improve productivity and achieve higher quality welding results.

PCL Machinery

Why Choose Us?

Expertise

We have years of experience in the industry and have helped many clients achieve their goals.

Quality

We are committed to providing the highest quality services to our clients.

Innovation

We are always looking for new and innovative ways to help our clients succeed.

Results

Our goal is to help our clients achieve their desired results and exceed their expectations.