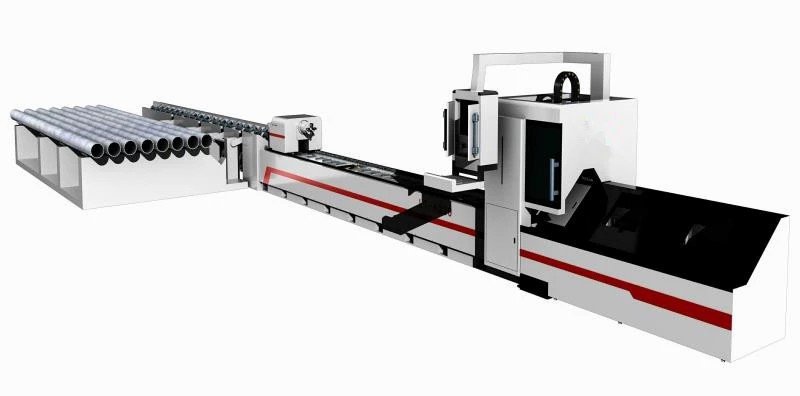

Rotary tube cutting machine

CNC tube cutting machine, Using rotary system, pipes diameter 40mm-1200mm Automatic controller system

machine cutting length: 6/12/15 meter

Special size needs to be customized

The Rotary system is a popular choice in tube steel cutting because it offers several advantages over other cutting methods.

Firstly, the Rotary system is highly accurate and precise. It allows for a clean, burr-free cut with minimal material waste. This makes it ideal for applications where precision is crucial, such as in the aerospace or automotive industries.

Secondly, the Rotary system is versatile and can handle a wide range of tube sizes and shapes. This means it can be used to cut everything from thin-walled tubing to thick-walled piping, and from round tubes to square or rectangular ones.

Thirdly, the Rotary system is fast and efficient, which makes it an excellent choice for high-volume production environments. It can cut multiple tubes simultaneously, which reduces production time and increases output.

Overall, the Rotary system is a reliable and cost-effective method for tube steel cutting, offering high precision, versatility, and efficiency.

we have different CNC Rotary tube cutting machine, there is always one to meet your processing requirements, contact us for price now

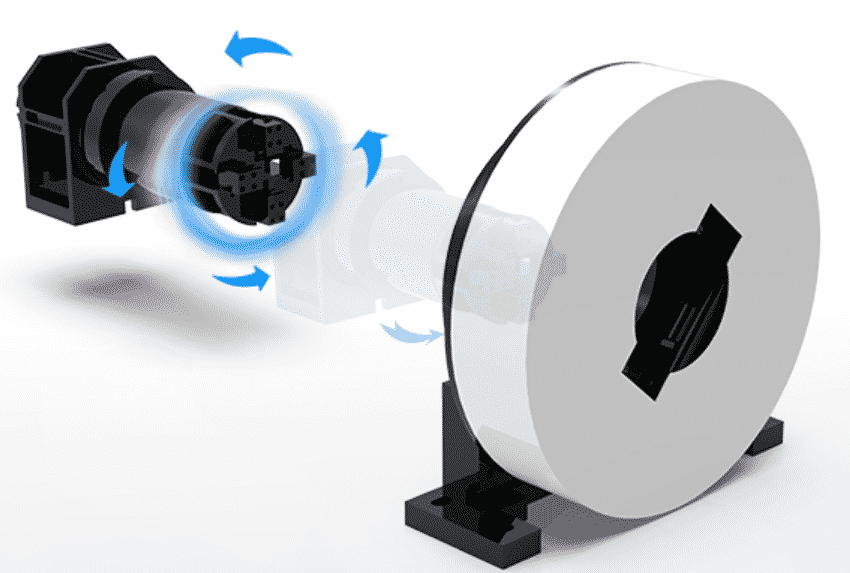

The term “double chuck” usually refers to two chucks or fixtures used to hold workpieces, In structural steel cutting, the use of a double chuck can offer a number of advantages:

Holding Stability: Dual chucks provide a more stable hold, ensuring that the workpiece does not move or twist during the cutting process. This is important to ensure cutting accuracy and workpiece quality.

Ideal for large workpieces: When working with large steel structures, using a double chuck provides better support and clamping of the workpiece to ensure stability. This is essential for accurate cutting of large structures.

Suitable for shaped parts: The design of the dual chuck allows it to be used for parts of different shapes and sizes. This increases the flexibility of the machine to adapt to different cutting needs.

Improved Cutting Quality: By providing a stronger clamping force, the dual chuck helps ensure that the workpiece is not subjected to vibration or distortion during the cutting process, contributing to improved cut quality and accuracy.

Reduced manual intervention: The dual chuck provides a more stable clamping during the cutting process, reducing the need for frequent operator intervention. This helps reduce operator workload while increasing safety.

Increased Cutting Versatility: The use of dual chucks allows for the simultaneous clamping of different types of workpieces, thereby increasing the versatility and flexibility of the production process.

Overall, dual chucks provide a more stable, efficient and accurate clamping solution in steel cutting, helping to optimize the production process and improve overall cutting performance.

All kinds of Plasma source and Fiber laser cutting system choose

Laser cutting is much different from Plasma cutting, If pipes is small, we advise you choose fiber laser tube cutting machine, If pipes is big, Plasma cnc tube cutting machine will be more suitable