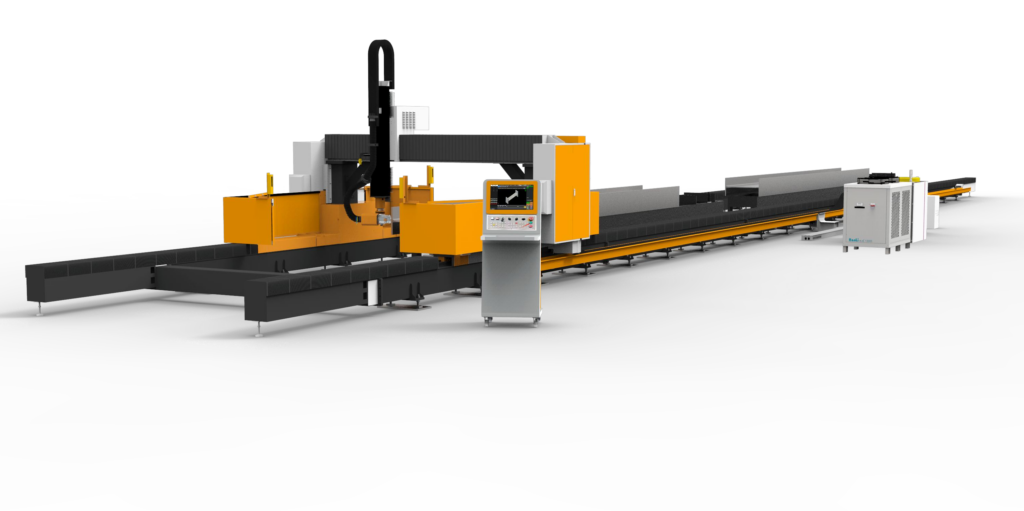

8-Axis CNC Plasma Cutting Machine

The 8-axis CNC plasma cutting machine stands as a premier 3D profiling solution for advanced industrial fabrication. This highly versatile system is engineered to perform complex operations on a wide array of structural profiles, including box profiling, beam profiling, and intricate pipe profiling. Its multi-axis configuration allows for superior flexibility, enabling the machine to handle geometries that traditional 2D cutters simply cannot reach.

By automating the entire cutting sequence through sophisticated computer programming, the 8-axis system guarantees a level of accuracy and repeatability that is essential for high-standard manufacturing. Whether it is for shipbuilding, bridge construction, or architectural steel, this machine ensures that every cut meets the most stringent tolerances, significantly reducing lead times and material waste.

Model Selection & Capacities

Robotic 3D Execution

The integrated robotic arm provides full 360-degree access to structural components, facilitating flawless bevel cuts and intersection holes. This precision eliminates the need for secondary manual finishing, expediting the assembly process.

Operational Efficiency

With its high-speed positioning and intelligent nesting software, the PCL 8-axis system optimizes material usage. It supports direct file imports from popular CAD platforms, ensuring a seamless digital-to-physical transition.

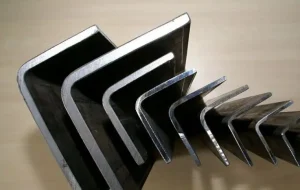

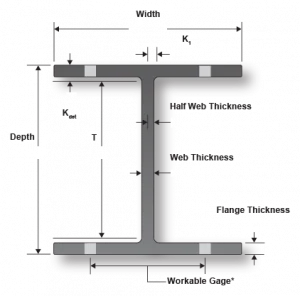

One Machine Cuts All

Our advanced 8-axis CNC system offers unmatched versatility, precisely cutting a comprehensive range of steel profiles to meet diverse fabrication needs.