What is the cnc tube laser cutter

A CNC tube laser cutter is a machine used to cut tubes and pipes with high precision and speed. It is a type of computer numerical control (CNC) machine that uses a laser beam to cut through metal, plastic, and other materials. The tube laser cutter uses a specialized laser that is optimized for cutting cylindrical shapes.

The CNC tube laser cutter is used in a variety of industries, including automotive, aerospace, and construction. It is commonly used to cut and shape metal tubes and pipes for various applications, such as roll cages, frames, and exhaust systems.

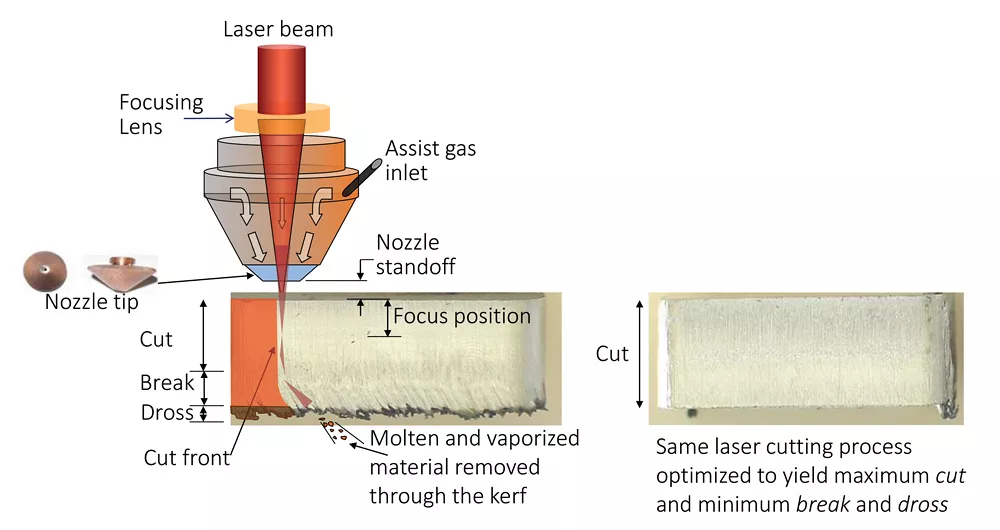

The machine works by directing a laser beam onto the surface of the tube or pipe, which melts and vaporizes the material. The laser moves along the length of the tube or pipe, cutting through it with precision and speed. The machine is operated using a computer program, which controls the movement of the laser and the cutting process.

CNC tube laser cutters are known for their high precision and accuracy, which allows for intricate and complex designs to be cut with ease. They are also much faster than traditional cutting methods, such as sawing or drilling, which makes them ideal for high-volume production runs.

Why choose the tube laser cutter

- There are several reasons why one might choose a tube laser cutter over other cutting methods:

- Precision: Tube laser cutters offer extremely high precision, allowing for accurate cuts to be made with minimal error. This precision can be especially important when working with complex geometries or tight tolerances.

- Efficiency: Tube laser cutting is a highly efficient process, with the ability to cut through thick materials quickly and accurately. This efficiency can save time and money in production processes, as well as reduce waste and material usage.

- Versatility: Tube laser cutters can be used to cut a wide range of metal, This versatility makes tube laser cutting a useful tool for a variety of industries and applications.

- Automation: Many tube laser cutters are fully automated, with the ability to load and unload materials automatically. This automation can increase productivity and reduce the need for manual labor.

- Cost-effectiveness: While the initial investment in a tube laser cutter can be significant, the cost-effectiveness of the technology over time can make it a worthwhile investment. Tube laser cutting can reduce material waste and labor costs, as well as increase production speed and efficiency.

why choose the fiber laser cnc cutting machine

Fiber laser cutting machine melt and pierce metals by uses a type of solid-state concentrated laser, When this powerful laser hits the metal surface, the high-intensity light is absorbed and converted into heat, which melts the surface. it is a precise and efficient cutting tool.

The Fiber laser cutters can cut a range of materials and thicknesses depending on laser power. maxmum cutting thickness can be 40mm.