Welding in Industrial Manufacturing: The Key to Efficiency and Quality

Welding is an indispensable process in industrial manufacturing. However, traditional welding methods often face challenges such as low efficiency, inconsistent quality, and high costs. The emergence of teaching-free robotic welding machines provides a perfect solution to these problems.

What is a Teaching-Free Robotic Welding Machine?

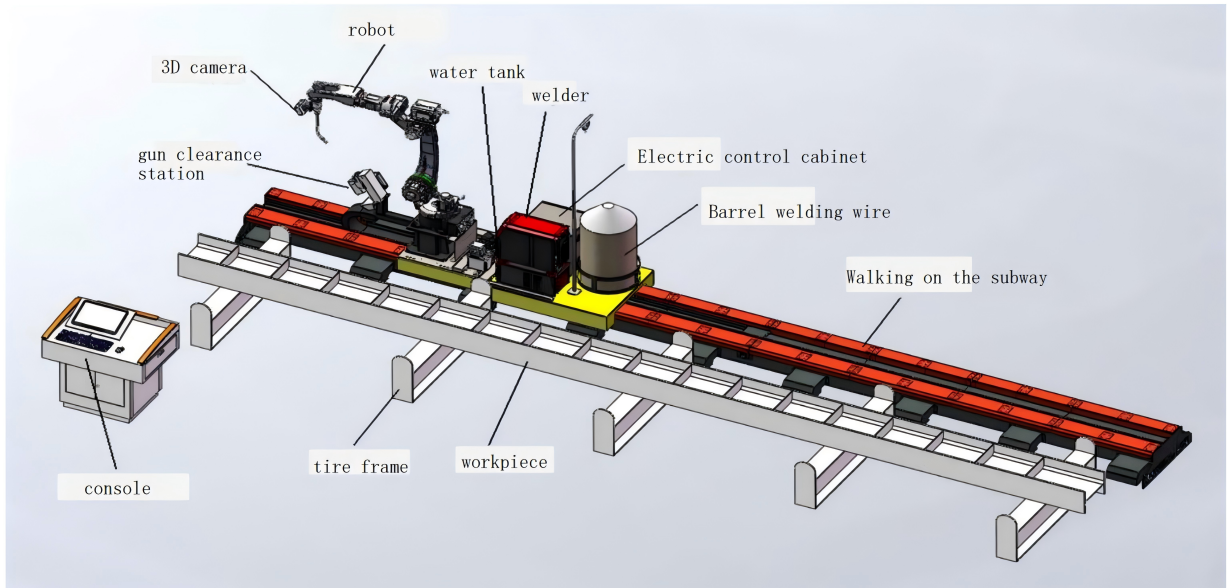

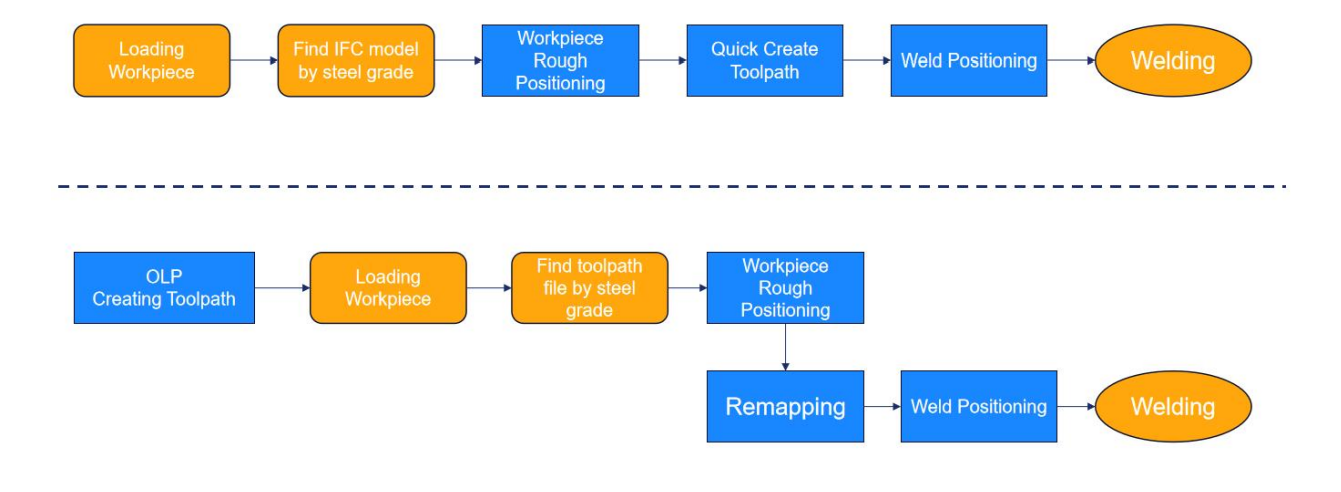

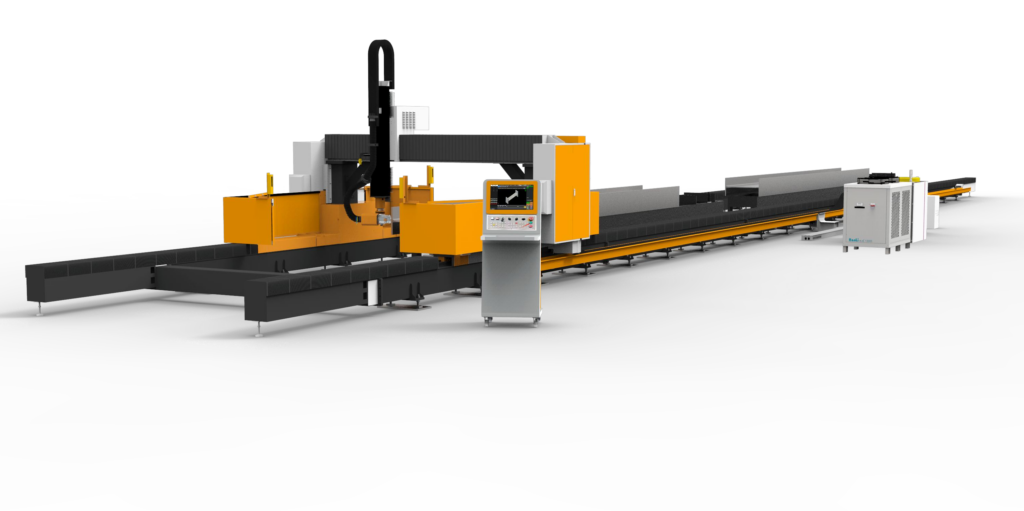

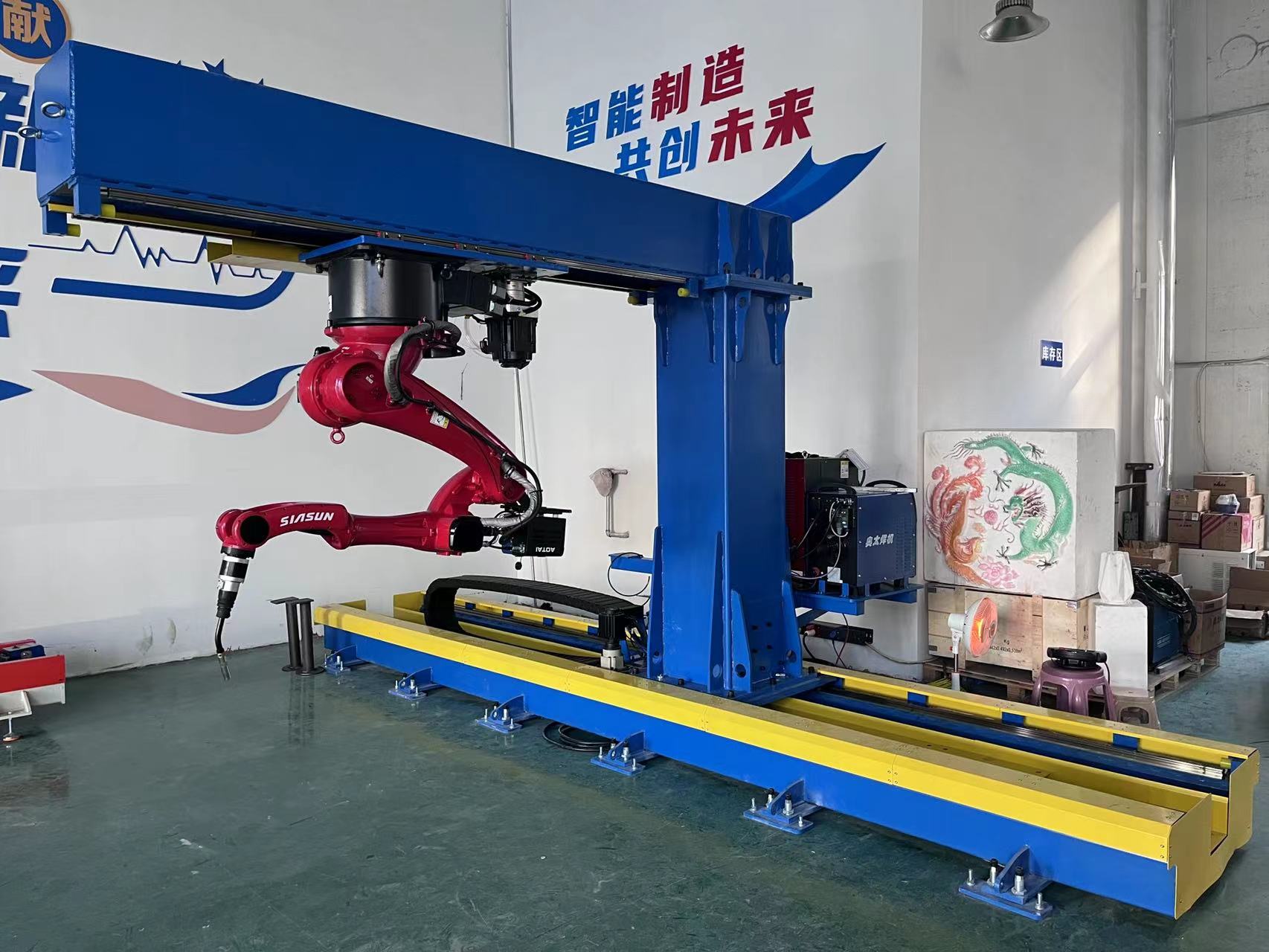

A teaching-free robotic welding machine is an intelligent welding device that integrates advanced visual recognition, path planning, and motion control technologies. It eliminates the need for manual teaching, automatically identifying weld seam positions, planning welding paths, and completing high-quality welding operations.

Advantages of a Teaching-Free Robotic Welding Machine

1. Enhanced Welding Efficiency

- No need for teaching, instant welding: Traditional welding robots require significant time for manual teaching, whereas teaching-free robotic welding machines can automatically recognize weld seams, drastically reducing programming time and increasing production efficiency.

- Continuous multi-workpiece welding: These machines can identify weld seams on different workpieces automatically, enabling continuous welding and further improving production efficiency.

2. Guaranteed Welding Quality

- Precise identification, stable welding: Advanced vision recognition systems precisely locate weld seams, ensuring accurate welding paths and avoiding welding deviations.

- Intelligent adjustment, high adaptability: The machine automatically adjusts welding parameters according to different materials and welding techniques, ensuring stability and consistency in welding quality.

3. Reduced Welding Costs

- Lower labor costs: Teaching-free robotic welding machines replace manual welding, significantly reducing labor expenses.

- Less material waste: Accurate welding path planning and parameter control reduce material waste and lower production costs.

- Improved equipment utilization: These machines operate 24/7, maximizing equipment utilization and reducing capital investment costs.

4. Improved Work Environment

- Reduced manual operation, lower safety risks: These robots handle welding in hazardous environments, minimizing safety hazards for workers.

- Lower smoke and dust pollution: Equipped with smoke purification systems, teaching-free robotic welding machines reduce welding fumes and improve the work environment.

5. Wide Range of Applications

Teaching-free robotic welding machines are suitable for welding various metal materials and are widely used in industries such as automotive manufacturing, construction machinery, rail transportation, shipbuilding, and pressure vessel production.

Why Choose a Teaching-Free Robotic Welding Machine?

✔ Efficient: Boosts welding productivity and shortens production cycles.

✔ High-Quality: Ensures superior welding quality and enhances product competitiveness.

✔ Cost-Effective: Reduces welding costs and improves business profitability.

✔ Safe: Improves the work environment and ensures worker safety.