In recent years, with the rising labor costs, the economic model of “Made in China,” which relied on cheap labor, has become unsustainable. As an “industrial seamstress,” welding is an essential processing method in industrial production. At the same time, due to the presence of welding fumes, arc light, and metal splashes, fewer people are willing to actively learn welding or engage in welding-related work. Under these circumstances, adopting robotic welding has become the most effective solution to address the labor shortage in China’s economic development process.

During the use of welding robots, welding programs are primarily created through teaching programming, where an operator guides the robot using a teaching device to record the required welding path. The precision of the taught points directly affects the welding quality and efficiency of the welding robot. Therefore, ensuring accuracy in the teaching process is crucial.

1. The Teaching Process of Welding Robots

The “teaching” process of a welding robot is essentially its learning process. Most robots are guided manually during teaching. In this process, the operator moves the welding torch along the weld seam according to its shape and position, simulating the welding process while the robot records the main points along the movement trajectory. This recorded path becomes the welding program. The accuracy of these taught points determines the precision of the welding gun’s movement trajectory, which in turn affects the accuracy of the weld seam position. Excluding the influence of welding parameter settings, the precision of the teaching process largely determines the weld quality.

2. Factors Affecting Welding Teaching Programming

(1) Insufficient Lighting

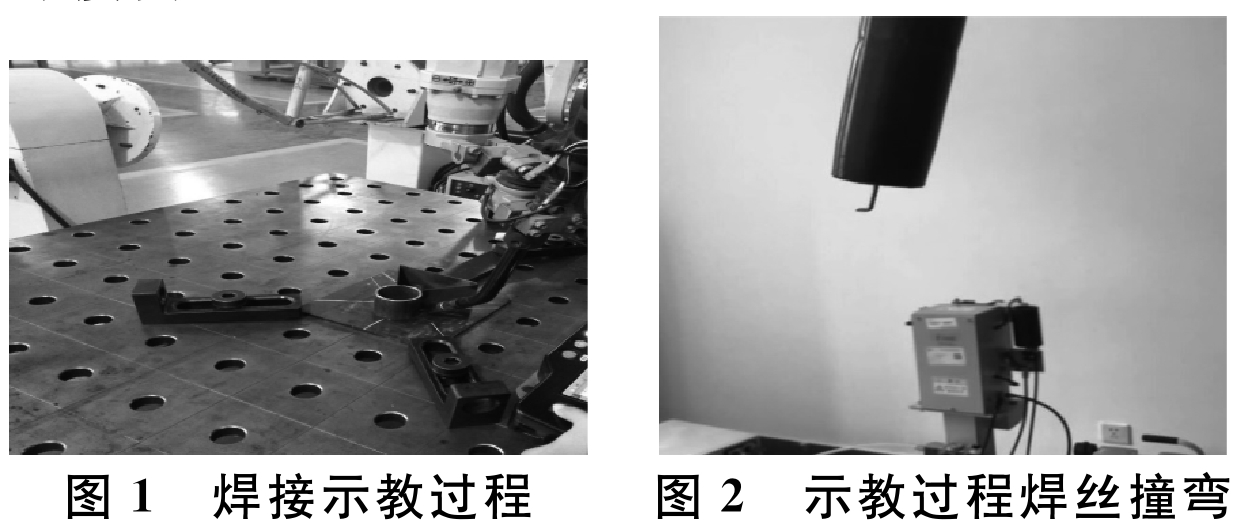

As shown in Figure 1, during the teaching process, we observed that lighting was significantly insufficient when teaching at corner weld positions. This made it difficult for operators to quickly find the correct point location. If the recorded point is inaccurate, it will affect the weld seam position and the overall welding quality.

(2) Variations in Wire Extension Length

During the teaching process, multiple robot axes continuously change positions and angles—sometimes extending, sometimes retracting. This movement causes the wire feeding hose installed on the robot’s upper arm to expand and contract, leading to variations in the welding wire extension length (typically maintained at 15mm). Since the taught position is usually determined based on the welding wire tip, any changes in this length will affect the accuracy of the taught position, resulting in welding inaccuracies.

(3) Welding Wire Bending Issues

As shown in Figure 2, due to the long length of weld seams and the large number of taught points, frequent wire bending occurs during the teaching process. This leads to reduced precision in point positioning, affecting welding quality.

3. Methods to Improve the Accuracy of the Welding Robot Teaching Process

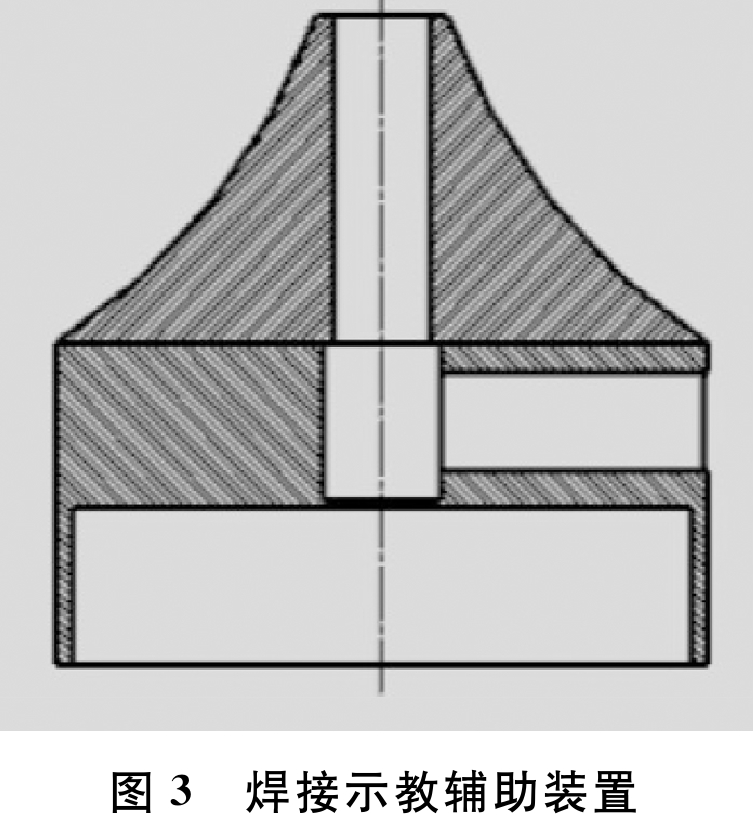

As shown in Figure 3, a rapid teaching programming assistance device for welding robots is introduced. This device is installed at the welding torch head, and its positioning corresponds to the previous 15mm welding wire extension length. Regardless of how the robot arm moves, this point remains unchanged, thereby eliminating the impact of wire extension variations on teaching accuracy.

Additionally, a high-intensity light is integrated into the device to improve visibility and address insufficient lighting issues during teaching.

Teaching Assistance Device Features:

- Made of plastic and equipped with a contact sensor.

- The sensor detects proximity to the teaching point:

- At 2mm distance, a red light illuminates.

- At 0.5mm distance, a green light illuminates.

- This feature allows for easy identification of the teaching point location.

- The material and contact sensor of the device help prevent collisions during teaching.

By implementing this auxiliary device, the welding robot teaching process can be significantly improved, enhancing accuracy and overall welding quality.