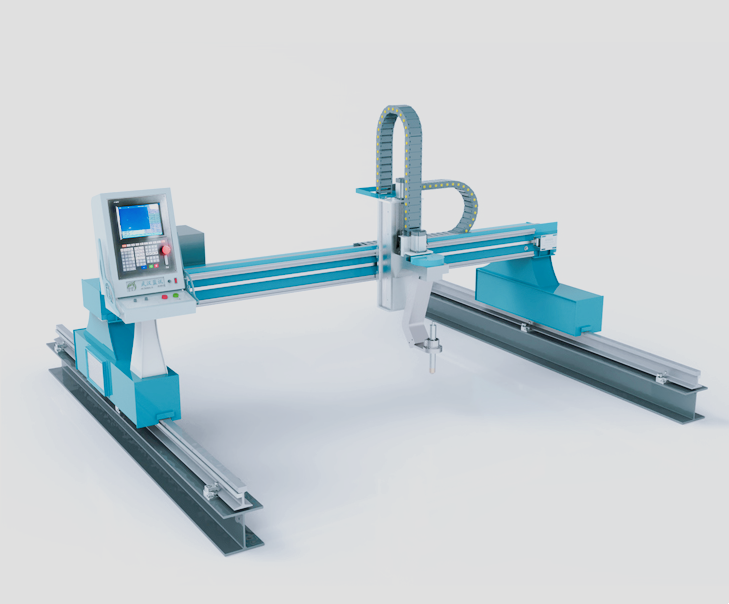

Plasma & Beam Cutting Solutions

Heavy-Duty CNC Plasma Systems for Pipes, Beams & Plate Processing

Frequently Asked Questions

What materials and profiles can be processed with these machines?

Our CNC machines support a wide range of materials including carbon steel, stainless steel, and various alloys. For profiles, in addition to standard round and square pipes, our H-Series and Structural Steel lines can process H-beams, channels, angles, and various custom profiles.

How does the machine handle pipe deformation or out-of-roundness?

The CNC Plasma Air Pipe Bevel Cutting Machine is equipped with an automated, servo-driven height sensing system. This technology compensates for vertical position variations caused by surface irregularities or pipe deformation, ensuring consistent bevel angles and cutting precision.

Can I import 3D design files directly into the control system?

Yes, our system is fully compatible with professional 3D design software like AutoCAD, Tekla, and Solidworks. It supports file formats such as IGES, DXF, SAT, and STL, allowing for seamless generation of CNC codes directly from your models.

What are the maximum pipe diameters and lengths supported?

Our standard machines cover pipe diameters from 40mm to 600mm, while custom solutions are available for larger diameters. Effective cutting lengths can be configured for 6m, 9m, 12m, or 15m to meet specific industrial requirements.