Top 5 Welding Robots with 2m Arm Reach for MAG Welding in 2025

Top 5 Welding Robots with 2m Arm Reach for MAG Welding in 2025 Introduction In 2025, MAG (Metal Active Gas) welding robots with approximately 2m

Oxy-acetylene pipe cutters are tools that use a mixture of oxygen and acetylene gases to cut through metal pipes. The process involves heating the metal to its kindling temperature with an oxy-acetylene flame and then using a high-pressure stream of oxygen to blow the metal away, creating a clean cut.

An oxy-acetylene CNC pipe cutter is a machine that uses oxy-acetylene gas to cut metal pipes in a precise and automated way. The machine is controlled by a computer numerical control (CNC) system that enables the cutting of pipes to be programmed and executed with a high degree of accuracy.

To operate the oxyacetylene CNC pipe cutting machine, the operator first enters the desired cutting parameters into the CNC, including the pipe diameter, the desired cut shape and angle, and the cutting speed. The machine then uses oxyacetylene gas to heat the metal pipe to high temperatures, melting and evaporating the metal in a controlled manner to form the desired cut shape.

1, high cutting quality

Generally speaking, the use of flame cutting is mostly used for medium-thick plate cutting process, similar material thickness are above 20MM, in this thickness basically, within 100MM thickness material cutting because it is not easy to change the line and perforation operation slagging easy to block the cutting nozzle, can be used to cut from the edge of the steel plate, in maintaining 0-700mm / min speed range cutting, can maintain the width of the cut in 2mm Meanwhile, it is equipped with automatic height adjustment control system to maintain the height of the cutting gun stable throughout the cutting process.

2、High verticality of cutting surface

Unlike CNC plasma cutting machine due to plasma arc caused by the V-shaped cutting surface, CNC flame cutting machine processing of the cut surface verticality is generally higher, the slope can be controlled at 2-3 ° or less, characterized by more than 10mm for a certain thickness of the plate cutting, better performance.

3, cutting thickness is large

In the actual processing applications, flame cutting process thickness range between 6-200MM, replace the gas pipe and torch nozzle, cutting thickness can even reach 350MM. in order to better improve the cutting quality, for different thicknesses of materials, when using flame cutting, the relevant process parameters will be slightly different

Top 5 Welding Robots with 2m Arm Reach for MAG Welding in 2025 Introduction In 2025, MAG (Metal Active Gas) welding robots with approximately 2m

In the world of metal fabrication, the gantry plasma cutting bevel machine stands out as a versatile and efficient tool. This advanced equipment combines the

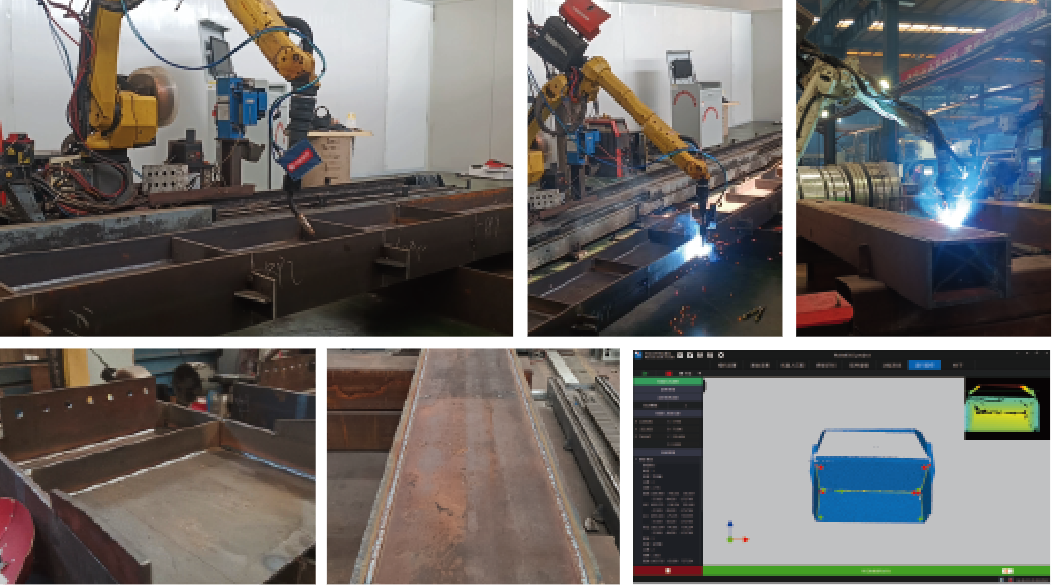

Technical Study on MAG Welding of Steel Structures by Welding Robots Abstract Metal Active Gas (MAG) welding, utilizing a consumable wire electrode and a shielding