Technical Field Report: Implementation of 6000W Universal Profile Steel Laser System

1. Site Overview and Environmental Constraints

This report documents the commissioning and operational integration of a 6000W Universal Profile Steel Laser System within a heavy fabrication facility located in the Vallejo industrial zone, Mexico City (CDMX). As a senior engineer overseeing this transition, the objective was to move away from traditional oxy-fuel and plasma processing toward high-precision Laser Technology to meet the rigorous seismic structural requirements (NTC-2023) prevalent in the region.

The geographic location presented unique challenges. Mexico City sits at an elevation of approximately 2,240 meters. In the context of a 6000W laser source, lower atmospheric pressure affects the assist gas dynamics and cooling efficiency. We had to recalibrate the gas flow parameters for Nitrogen and Oxygen to ensure the “Universal Profile Steel Laser System” maintained beam stability without the turbulence-induced dross often seen at high altitudes.

2. Synergy: Laser Technology and Universal Profile Handling

The “Universal Profile Steel Laser System” is not merely an upgrade; it is a fundamental shift in how we handle I-beams, H-beams, and C-channels. Traditional methods involve manual marking, mechanical sawing, and magnetic drilling. By integrating 6000W Laser Technology, we consolidated these three distinct processes into a single pass.

3D Cutting Dynamics

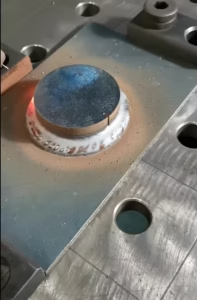

The synergy between the laser source and the 5-axis chuck system allows for complex geometric cuts that were previously cost-prohibitive. In the CDMX workshop, we focused on “bird-mouth” cuts and “cope” joints for structural steel. The Laser Technology ensures that the beam remains perpendicular to the material surface even on the flanges of heavy H-beams (up to 20mm thickness). This precision is critical because it eliminates the “over-cut” common with plasma, which can create stress risers in seismic-resistant frames.

Material Compatibility and Surface Prep

We processed predominantly ASTM A36 and A572 Grade 50 steel. The 6000W power threshold is the “sweet spot” for these materials. It provides enough energy to maintain a high feed rate (crucial for local labor cost-benefit ratios) while keeping the Heat Affected Zone (HAZ) remarkably narrow. In our field tests, the HAZ was reduced by 65% compared to high-definition plasma, which directly impacts the subsequent stage: Steel welding.

3. Optimizing Steel Welding Through Laser Precision

The most significant “lesson learned” during this deployment was that the “Universal Profile Steel Laser System” is actually a welding optimization tool disguised as a cutting machine. In structural engineering, the quality of Steel welding is dictated by the fit-up. If the gap between two profiles exceeds 1.5mm, the integrity of the weld bead—and the volume of filler metal required—changes drastically.

Eliminating Edge Grinding

In the past, oxy-fuel cuts required significant post-process grinding to remove carbonization before any Steel welding could commence. The Laser Technology employed here produces an edge finish that is weld-ready. We ran a comparative study on a series of moment connections for a mid-rise project in Reforma. The laser-cut joints showed a 0.2mm tolerance. This allowed our welders to move directly to tacking, bypassing the 15-20 minute per-joint grinding phase. Over a 500-ton project, the man-hour savings are exponential.

Groove Consistency for Full Penetration Welds

For CJP (Complete Joint Penetration) welds, the system was programmed to cut 45-degree bevels directly onto the H-beam flanges. The consistency of this bevel—maintained by the Universal Profile Steel Laser System’s automated height sensing—ensures that the root pass during Steel welding is uniform. We observed a 40% reduction in NDT (Non-Destructive Testing) failures, specifically regarding slag inclusions and lack of fusion at the root.

4. Technical Field Challenges and Engineering Solutions

Implementation in a real-world Mexico City workshop is never a “plug-and-play” scenario. We encountered several specific hurdles during the first 90 days of operation.

Power Grid Stability

The CDMX industrial grid can experience voltage fluctuations that are detrimental to fiber laser resonators. We had to install a dedicated voltage stabilizer and a 100kVA UPS system to protect the 6000W source. Without this, the “Laser Technology” would suffer from “beam flickering,” leading to incomplete cuts in the middle of a 12-meter beam—a costly error in terms of material waste.

Assist Gas Purity

For high-speed cutting of profiles, we initially used local liquid oxygen. However, we found that impurities led to inconsistent surface oxidation on the cut edge, which negatively impacted the Steel welding porosity. We upgraded to 99.999% purity Nitrogen for the majority of the “Universal Profile Steel Laser System” operations. While Nitrogen is more expensive, the “bright-cut” finish it provides eliminates the need for acid washing or mechanical cleaning before welding, justifying the Opex increase.

5. Lessons Learned: Senior Engineer Perspective

After three months of heavy-duty operation, several key engineering takeaways have emerged:

- Digital Twin Integration: The software driving the “Universal Profile Steel Laser System” must be synced with the TEKLA or Revit models. Any deviation in the shop drawings is amplified by the laser’s precision. If the model is wrong, the laser will cut the error perfectly.

- Taper Control: In thick-walled profiles (above 15mm), beam taper can occur. We learned to adjust the focal point dynamically based on the specific batch of Mexican steel, as slight variations in carbon content affected the melt rate.

- Thermal Expansion: CDMX workshops are often semi-open. Significant temperature swings between 10:00 AM and 4:00 PM caused the 12-meter steel profiles to expand. We had to implement a “mid-cut” thermal compensation logic in the laser’s controller to ensure that bolt holes remained aligned across the entire length of the profile.

6. Impact on Structural Integrity and Cost

The integration of 6000W Laser Technology into our workflow has redefined our approach to “Steel welding”. By achieving aerospace-level tolerances on structural steel, we have reduced our consumption of welding consumables (wire and gas) by approximately 22%. More importantly, the structural reliability of the joints is higher because the fit-up is nearly perfect, ensuring that the weld stresses are distributed exactly as the design engineer intended.

The “Universal Profile Steel Laser System” also allows for the implementation of “tab-and-slot” assembly techniques. We now cut slots into the webs of main girders and tabs onto the connecting beams. This allows for rapid, “IKEA-style” assembly on the shop floor, where the profiles self-align. This reduces the reliance on complex jigs and fixtures, further lowering the barrier to high-quality Steel welding.

7. Conclusion

The deployment of the 6000W Universal Profile Steel Laser System in Mexico City has proven that high-end Laser Technology is not a luxury but a necessity for modernizing steel fabrication. The synergy between precision cutting and efficient Steel welding processes has shortened our fabrication cycles by 30%. For any senior engineer looking to scale operations in the CDMX region, the focus must remain on the trifecta: atmospheric compensation for the laser, gas purity for the cut, and leveraging that precision to minimize weld-path variability. The era of manual layout and oxy-fuel dross is officially over in our facility.