12kW H-Beam Laser Cutting Machine Infinite Rotation 3D Head for Bridge Engineering in Katowice

Field Eval: 12kW H-Beam Laser integration in Katowice bridge works. Infinite 3D Head optimizes V/K-bevels, reducing HAZ and eliminating secondary milling.

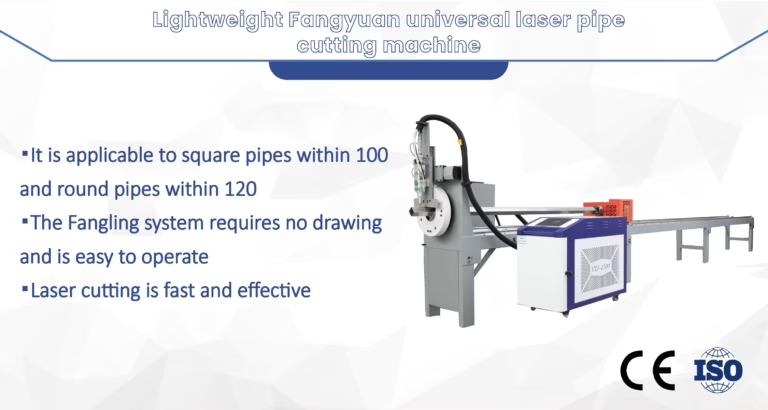

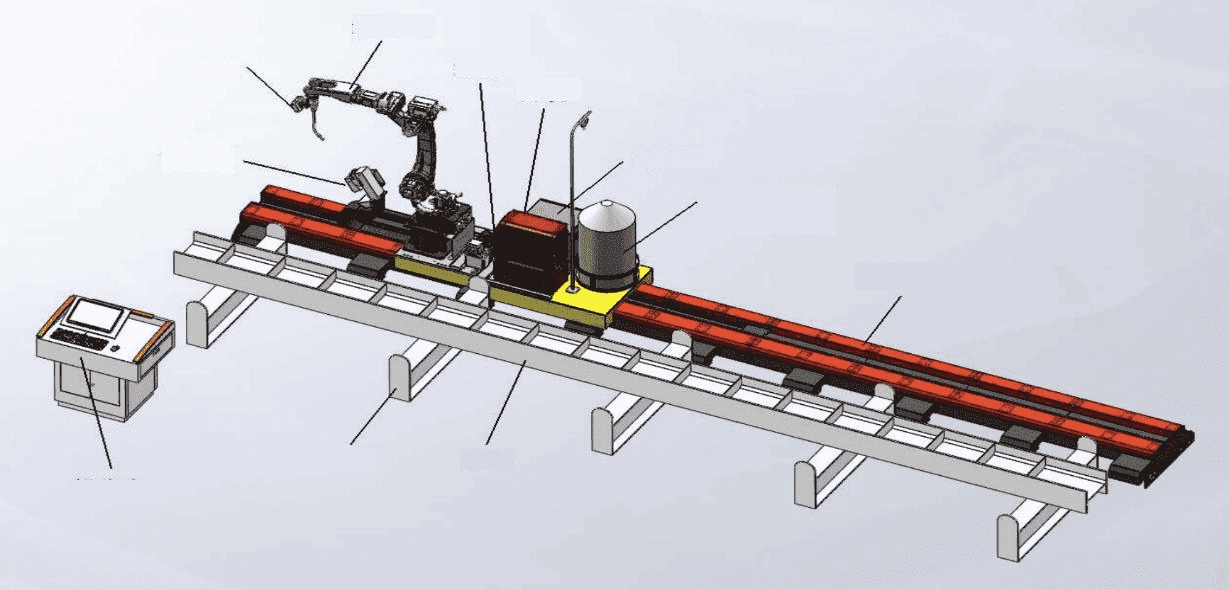

The CNC tube laser cutting machine is a type of industrial machinery that uses a high-powered laser to cut various types of metal tubing and pipes with high precision and speed. The machine typically consists of a laser cutting head, a tube feeding system, and a computerized control system.

The laser cutting head of the machine is equipped with a high-power laser that generates a focused beam of light. This beam is directed onto the surface of the tube or pipe to be cut, and the intense heat of the laser vaporizes or melts the metal, creating a precise cut.

The tube feeding system of the machine is designed to hold and position the tube or pipe during the cutting process. The computerized control system of the machine uses advanced software to create detailed cutting instructions and control the movement of the laser cutting head and the tube feeding system.

Tube laser cutting machines are often used in industries such as automotive manufacturing, aerospace, and construction to create complex metal components and structures with high precision and efficiency.

If you’re interested in purchasing a tube laser cutting machine, here are some steps to consider:

Determine your needs: First, consider the type of materials you’ll be cutting and the volume of production you need. This will help you determine the size and power of the machine you require.

Research manufacturers: Look for reputable manufacturers of tube laser cutting machines. Read reviews, compare prices, and evaluate their customer service.

Request quotes: Once you have identified a few potential manufacturers, request quotes for the machines that meet your needs. Make sure to ask about any additional fees or costs.

Consider financing options: Tube laser cutting machines can be expensive, so you may need to consider financing options. Some manufacturers offer financing or leasing programs.

Visit the manufacturer: If possible, visit the manufacturer to see the machines in action and ask any questions you may have.

Make a decision: After evaluating all of the information you’ve gathered, make a decision on which machine to purchase.

Arrange for delivery and installation: Once you’ve made your purchase, arrange for delivery and installation of the machine. Make sure to have a plan in place for training your staff on how to use the machine safely and effectively.

Overall, buying a tube laser cutting machine requires careful consideration of your needs, research into manufacturers, and a clear understanding of the costs involved.

Field Eval: 12kW H-Beam Laser integration in Katowice bridge works. Infinite 3D Head optimizes V/K-bevels, reducing HAZ and eliminating secondary milling.

Precision Engineering: The 2kW Sheet Metal laser cutting Guide for Aluminum Alloys in Monterrey Monterrey, Nuevo León, has long been established as the industrial heart

The integration of 6000W CNC fiber laser technology with infinite rotation 3D cutting heads represents a paradigm shift for Dubai’s burgeoning railway sector. As the UAE expands its national rail network and enhances urban transit systems, the demand for precision-engineered structural steel—specifically H-beams, I-beams, and channels—has reached an all-time high. This expert analysis explores how 6000W of fiber laser power, combined with five-axis cinematic freedom, overcomes the environmental challenges of the Middle East while delivering the structural integrity required for high-speed rail infrastructure.

Fill out the form below, and we will be in touch shortly.