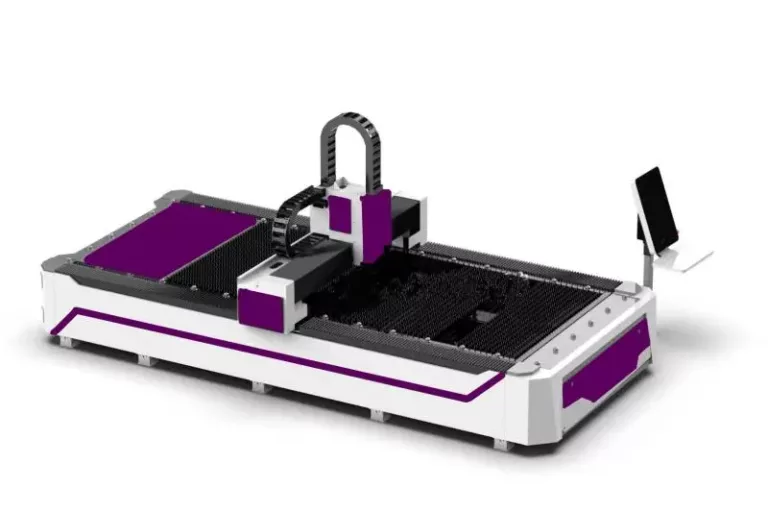

Why choose the laser cutting machine to cut 20mm steel

Laser cutting machines are an excellent choice for cutting 20mm steel because they offer several advantages over other cutting methods, such as plasma cutting or oxyfuel cutting.

Firstly, laser cutting is a non-contact process, which means that the laser beam does not physically touch the material being cut. This results in a very precise cut, with minimal heat affected zones and distortion, which is especially important when cutting thicker materials like 20mm steel.

Secondly, laser cutting machines are very fast and efficient, with high cutting speeds and the ability to cut complex shapes with a high degree of accuracy. This means that you can get your cutting jobs done quickly and efficiently, which can save you time and money.

Finally, laser cutting machines are also very versatile and can be used to cut a wide range of materials, including steel, aluminum, and even some non-metallic materials like plastics and wood.

Overall, if you need to cut 20mm steel, a laser cutting machine is an excellent choice due to its precision, speed, efficiency, and versatility.

how to use the laser cutting machine cut 20mm steel?

Laser cutting 20mm steel is possible with a high-powered laser cutting machine. However, it requires careful consideration of several factors to achieve a successful cut.

Firstly, the laser cutting machine must have a sufficient power output to cut through the thickness of the steel. A fiber laser cutting machine with a power output of at least 6 kW is typically required for cutting 20mm thick steel.

Secondly, the cutting speed and feed rate must be carefully adjusted to ensure a clean cut without burrs or other defects. The optimal cutting speed and feed rate will depend on the specific laser cutting machine and the type of steel being cut.

Thirdly, it is important to ensure that the steel is properly supported during the cutting process to prevent warping or other distortion. This may require the use of additional fixtures or supports.

Finally, appropriate safety measures must be taken when laser cutting steel, including the use of personal protective equipment and ensuring proper ventilation to prevent the buildup of hazardous fumes.

Overall, laser cutting 20mm steel requires a high-powered laser cutting machine, careful attention to cutting parameters, proper material support, and appropriate safety measures.

CNC Plasma cutting machine is a cheap enquipment to choose from in the market. When cutting thick metal, plasma will be faster and cheaper, Fiber laser cutting machine improves cut precision, quality and production yield, providing superior parts at lower prices, but price will be higher than plasma cutting machine