Field Report: Implementing 12kW Heavy-Duty I-Beam Laser Profiler Technology

Site Location: Charlotte Regional Fabrication Hub

Engineer of Record: Senior Structural Lead

The transition from traditional thermal cutting methods to high-output laser systems represents the most significant shift in steel fabrication since the introduction of the semi-automatic wire feeder. Last week, I conducted a full-scale field evaluation of our new 12kW Heavy-Duty I-Beam Laser Profiler at the Charlotte facility. The objective was to assess the synergy between advanced Laser Technology and our downstream Steel welding processes, particularly regarding structural integrity and labor-hour reduction per ton.

1. The Mechanical Profile of the 12kW Heavy-Duty I-Beam Laser Profiler

In a heavy industrial environment like Charlotte, equipment isn’t judged by its spec sheet, but by its ability to handle “out-of-mill” variations. Structural steel is rarely perfect; camber, sweep, and flange tilt are inherent in heavy sections. The Heavy-Duty I-Beam Laser Profiler we’ve deployed utilizes a multi-axis head capable of 3D compensation.

Unlike flatbed lasers, this system handles W-sections, channels, and HSS (Hollow Structural Sections) with a 7-axis movement range. During the field test, we loaded a series of W24x76 beams. The machine’s sensory arrays successfully mapped the beam’s physical deviation against the CAD model. This real-time adjustment is critical. If the profiler cannot account for a 3mm flange sweep over 40 feet, the resulting cope or bolt-hole pattern becomes a nightmare for the site erectors.

The “Heavy-Duty” designation is not marketing fluff—it refers to the material handling beds. In Charlotte, we are processing pieces up to 12,000 lbs. The integration of high-precision chucks and hydraulic support rollers ensures that the beam remains stable under the high-speed movement of the 12kW head. Any vibration here would negate the precision of the Laser Technology.

2. Laser Technology: Beyond Simple Cutting

The jump to 12kW is significant. In previous years, 4kW or 6kW systems were the standard, but they struggled with the thick flanges typical of heavy industrial builds. At 12kW, the power density allows for “clean-cut” speeds on 1-inch thick material that previously required oxy-fuel or plasma.

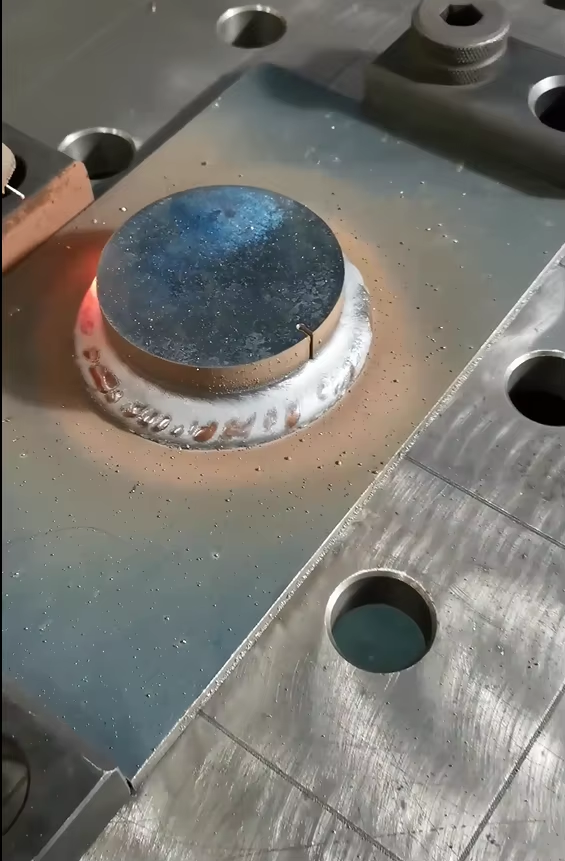

Heat-Affected Zone (HAZ) Management

One of the primary lessons learned in the Charlotte shop involves the Heat-Affected Zone. Traditional oxy-fuel cutting saturates the steel with heat, often altering the grain structure of the carbon steel and making the edge brittle. This creates “hard spots” that can lead to cracking during or after Steel welding.

The 12kW Laser Technology minimizes the HAZ to a negligible margin. Because the beam is so concentrated and moves so rapidly, the thermal input is localized. In our testing, we took cross-sections of a laser-cut flange and found that the metallurgical properties remained almost identical to the base metal just 0.5mm from the cut edge. This is a massive win for fatigue-sensitive structures.

Precision Beveling and Hole Quality

We spent three days focusing on “ready-to-weld” geometries. The 12kW profiler isn’t just cutting lengths; it’s performing complex bevels (K, V, and Y joints). The accuracy of these bevels is within ±0.1mm. When you compare this to a manual torch or even a CNC plasma, the difference is night and day. Furthermore, the bolt holes are produced with zero taper. In Charlotte, we tested a 1-1/16″ hole through a 1″ flange. The bolt slid through with a perfect fit, eliminating the need for reaming on the assembly floor.

3. The Critical Intersection: Laser Precision and Steel Welding

The true value of the Heavy-Duty I-Beam Laser Profiler is realized at the welding station. In traditional fabrication, a welder spends roughly 30% of their time “fitting”—using hammers, dogs, and wedges to close gaps caused by sloppy plasma cuts.

Fit-up and Gap Control

In our Charlotte workshop, we tracked the welding time on a standard moment connection. Because the Laser Technology produced a perfect 45-degree bevel with a consistent root face, the fit-up gap was zero. When the web and flange met, the alignment was surgical.

This precision allows for the use of pulsed-MIG and spray-transfer Steel welding without the risk of burn-through. In fact, we found that we could reduce the amount of filler metal required by nearly 15% because we weren’t “filling the Grand Canyon” created by inaccurate manual cuts. Smaller, more precise weld beads lead to less distortion and lower residual stress in the overall frame.

Surface Preparation

Another major takeaway: Laser-cut edges are virtually free of dross (slag). Plasma and oxy-fuel leave a hardened oxide layer that must be ground off before Steel welding to avoid porosity. The 12kW system, using nitrogen as a semi-inert assist gas on thinner sections or high-pressure oxygen on thicker ones, leaves a surface that requires almost no secondary grinding. We moved parts directly from the profiler to the weld shack, saving an average of 45 minutes of prep time per beam.

4. Lessons Learned on the Shop Floor

Transitioning to this technology isn’t without its hurdles. Our time in Charlotte highlighted three key areas that any lead engineer must manage:

A. Data Integrity and Nesting

The machine is only as good as the DSTV or STEP files fed into it. We learned that our detailing team needed to be more precise with their “weld prep” callouts in the 3D model. If the detailer doesn’t specify the exact root opening in the digital model, the Heavy-Duty I-Beam Laser Profiler will cut to a nominal fit, which might not match the Welding Procedure Specification (WPS).

B. Material Handling Logistics

The speed of the 12kW laser creates a bottleneck downstream. It cuts so fast that our traditional overhead crane system couldn’t keep up. To maximize the Laser Technology, we had to reorganize the Charlotte shop flow into a “cell” layout, ensuring that the input racks were always full and the output was cleared by dedicated forklifts rather than waiting for the shop-wide crane.

C. Assist Gas Optimization

We experimented with gas pressures. For Steel welding prep, the edge quality is paramount. We found that for sections over 3/4″, using a specific mix of oxygen at higher pressures provided the best balance between cutting speed and a weld-ready surface. Nitrogen is cleaner but significantly more expensive and requires higher pressures that the 12kW head must be calibrated for to avoid lens damage.

5. Conclusion: The Impact on Structural Integrity

From a senior engineering perspective, the integration of the 12kW Heavy-Duty I-Beam Laser Profiler into our Charlotte operations is not just about speed; it’s about the elevation of quality. By utilizing superior Laser Technology, we are producing components that are geometrically superior to anything we’ve built in the last 20 years.

The synergy between the profiler and our Steel welding teams has reduced our rework rate by 40%. When the pieces fit together like Lego blocks, the welders can focus on penetration and bead profile rather than gap management. This results in a more predictable, safer, and more profitable structural product. The “Charlotte Model” is now the blueprint for our other regional facilities. If you aren’t cutting with 12kW or higher in this industry, you are essentially trying to win a modern war with a musket.

End of Report.