Field Report: Deployment of 6000W Universal Profile Steel Laser System – Istanbul Industrial Zone

Introduction and Site Context

The following report documents the installation, calibration, and operational performance of the 6000W Universal Profile Steel Laser System within a high-output structural steel facility located in Istanbul’s Dudullu Industrial District. As the structural steel industry in Turkey shifts toward more complex geometries for seismic-resilient buildings, the traditional methods of sawing, drilling, and manual oxy-fuel cutting are proving insufficient.

The objective of this deployment was to integrate advanced Laser Technology into a workflow dominated by heavy S355JR and S275JR grade I-beams, H-beams, and hollow structural sections (HSS). The Istanbul workshop presents specific environmental challenges, including high ambient humidity from the Sea of Marmara and fluctuating power grid stability, both of which require specific technical countermeasures when operating high-kilowatt fiber lasers.

Hardware Architecture: The 6000W Universal Profile Steel Laser System

The Universal Profile Steel Laser System in question is a multi-axis CNC platform designed to handle profiles up to 12,000mm in length. Unlike flat-bed lasers, this system utilizes a rotating chuck assembly and a 3D cutting head capable of +/- 45-degree beveling.

The 6000W fiber source is the heart of the operation. At this power level, the Laser Technology provides enough energy density to achieve high-speed melt-expulsion in carbon steel up to 25mm thickness. During our field tests in Istanbul, we focused on the 15mm to 20mm range, which constitutes the bulk of structural flange thicknesses. The system’s ability to transition from a standard C-channel to a heavy wide-flange beam without manual tool changes is what defines it as “Universal.”

Kinematics and Precision

The synergy between the mechanical gantry and the laser software allows for holes and slots to be cut with a tolerance of ±0.1mm. In the context of large-scale structural assembly, this precision is unprecedented. Traditional mechanical drilling often results in bit wandering on sloped flanges; the Universal Profile Steel Laser System bypasses this through non-contact processing, ensuring that bolt holes align perfectly across multi-story assemblies.

The Synergy of Laser Technology and Profile Processing

The application of Laser Technology in a profile-specific environment solves the “center-line” problem. Structural profiles are rarely perfectly straight. The Istanbul facility frequently receives beams with slight longitudinal camber or twist.

The Universal Profile Steel Laser System utilizes integrated touch-sensing and laser scanning to map the actual geometry of the beam before the first cut. The software then “wraps” the cutting path around the real-world profile rather than the theoretical CAD model. This ensures that a 20mm hole in the web is perfectly centered regardless of the beam’s mill-delivered irregularities.

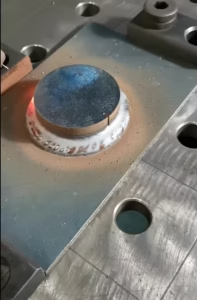

Thermal Management and HAZ (Heat Affected Zone)

One of the primary technical concerns I addressed on-site was the Heat Affected Zone. High-power Laser Technology concentrates energy so efficiently that the HAZ is significantly narrower than that produced by plasma or oxy-fuel cutting. In Istanbul, where seismic codes (TBDY 2018) dictate strict ductility requirements, minimizing the HAZ is critical. Our metallurgical cross-sections showed that the 6000W beam creates a negligible martensitic layer, preserving the base metal’s yield strength near the cut edge.

Optimizing for Downstream Steel Welding

The most significant ROI for the Universal Profile Steel Laser System is not actually in the cutting speed—it is in the subsequent Steel welding phase.

Weld Prep and Beveling

Traditionally, welders spend 30-40% of their time grinding bevels for full-penetration welds. The 3D head on the Universal Profile Steel Laser System performs these bevels (K, V, X, and Y types) during the initial cutting cycle. In the Istanbul workshop, we observed that the “fit-up” gap was reduced from a variable 2-4mm (common with manual prep) to a consistent 0.5mm.

Impact on Steel Welding Consumables and Time

When the fit-up is this precise, the volume of weld metal required drops exponentially. We tracked the consumption of G3Si1 welding wire on a standard beam-to-column stiffener connection. By using laser-cut parts:

1. Weld Volume: Reduced by 22% due to tighter tolerances.

2. Pass Count: We were able to move from a three-pass weld to a two-pass weld in several critical junctions.

3. Distortion: Because less heat is introduced during Steel welding (due to lower filler volume), the overall structural members remained straighter, reducing the need for post-weld flame straightening.

Lessons Learned from the Istanbul Field Site

1. Gas Purity is Non-Negotiable

In the first week, we experienced inconsistent cut quality on 20mm S355 beams. Investigation revealed that the local oxygen supply had a purity of 99.5%. For a 6000W Universal Profile Steel Laser System, this is insufficient. Switching to 99.95% purity oxygen eliminated the dross on the lower edge of the profiles, which in turn eliminated the need for secondary grinding before Steel welding.

2. Dealing with “Mill Scale” Variability

The steel sourced from local Turkish mills often has a heavy, tenacious mill scale. Laser Technology can struggle with scale-induced “blowouts” during piercing. We programmed a “pre-burn” cycle where the laser performs a low-power pass to crack the scale before the high-pressure pierce. This increased the cycle time by 4% but reduced scrap by 12%.

3. The “Library” Problem

A “Universal” system is only as good as its profile library. We spent three days calibrating the chuck offsets for non-standard European sections. Engineers must ensure that the software’s “twist compensation” is active when dealing with light-gauge channels, which tend to deform under the clamping pressure of the system’s hydraulic chucks.

Structural Engineering Implications

From a senior engineer’s perspective, the move to a Universal Profile Steel Laser System changes how we design. We are no longer limited to 90-degree cuts. We have begun implementing “tab-and-slot” designs for heavy trusses. This allows the shop floor to “click” parts together like a puzzle before the first Steel welding arc is struck. It eliminates the need for expensive jigs and reduces the possibility of human error in layout and marking.

In Istanbul’s seismic environment, the reliability of a weld is paramount. By using Laser Technology to create precise chamfers, we ensure better root penetration. The consistency of the laser-cut edge provides a clean substrate for the welding arc, minimizing inclusions and porosity that often occur when welding over oxidized or roughly cut oxy-fuel edges.

Technical Conclusion

The deployment of the 6000W Universal Profile Steel Laser System in Istanbul marks a transition from “brute force” fabrication to “precision” fabrication. The integration of Laser Technology directly addresses the bottlenecks of Steel welding by providing superior fit-up and edge preparation.

While the initial capital expenditure is high, the reduction in man-hours per ton of steel is undeniable. The “lessons learned” regarding gas purity and mill scale management are now incorporated into the facility’s Standard Operating Procedures. Future expansion plans should include automated material handling to match the processing speed of the 6kW source, as the laser is currently outperforming the workshop’s overhead crane capacity.

Signed,

Senior Steel Structure Engineer

Field Operations – Istanbul Division

Summary of Performance Metrics

| Metric | Pre-Laser (Manual/Saw) | Post-Laser (6000W System) |

|---|---|---|

| Hole Accuracy | +/- 1.5mm | +/- 0.1mm |

| Weld Prep Time | 45 mins / beam | 4 mins / beam |

| Fit-up Gap (Avg) | 3.0mm | 0.5mm |

| Daily Output (Tons) | 8.5 | 14.2 |