Our company is committed to promoting green and energy-efficient production by implementing advanced technologies. We have introduced an infinite rotary cutting system, which has significantly improved production efficiency and precision in multiple engineering applications. This system ensures component quality while achieving energy conservation and environmental protection goals.

1. Introduction to the Infinite Rotary Cutting System

The increasing complexity and diversity of steel structure buildings require higher standards for cutting and welding technology. To meet these demands, our company has introduced the infinite rotary cutting system, which has proven highly effective in processing complex and irregular components.

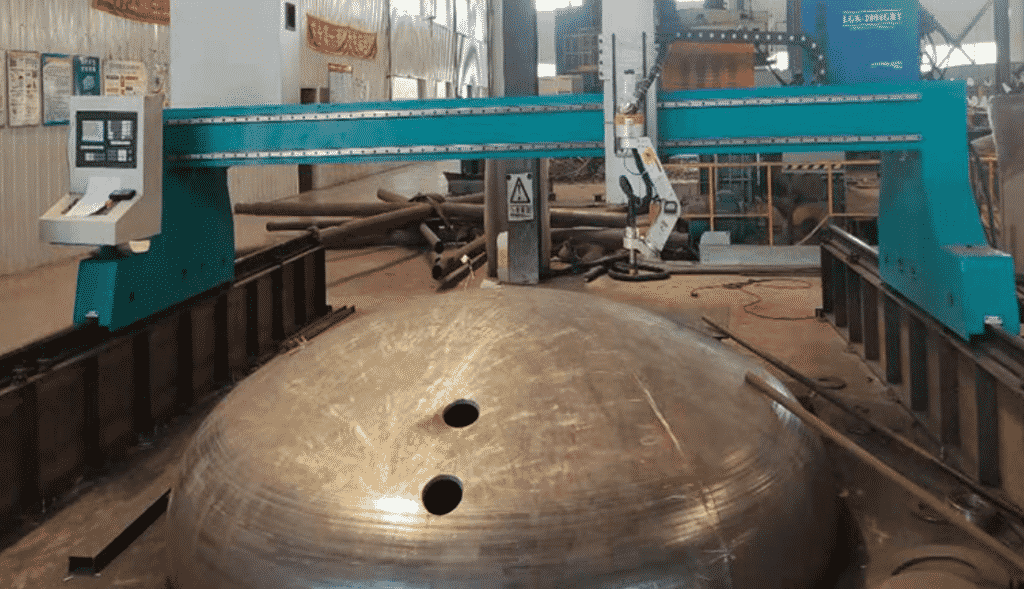

This system features a plasma CNC cutting machine (see Figure 1), characterized by high efficiency, high precision, lightweight structure, low inertia, and smooth operation. It is suitable for cutting various materials, including low-carbon steel and stainless steel.

1.1 Mechanical Structure of the Cutting Equipment

The machine consists of a crossbeam and two longitudinal end frames, with low-positioned end frames ensuring stability. The main transverse cutting torch operates via gear and rack transmission, while secondary torches move synchronously through a tensioned steel belt drive. The longitudinal movement is achieved using single- or dual-side drive gear-rack transmission, with guide wheels ensuring high positioning accuracy.

The bevel cutting system adopts a dual-pivot swinging structure (see Figure 2), which enhances cutting precision for complex profiles.

2. Advantages of the Infinite Rotary Cutting System in Steel Processing

2.1 Reduced Processing Steps and Time Savings

- The integration of CNC technology with the infinite rotary cutting system enables one-step processing of both material cutting and beveling, eliminating secondary bevel machining.

- Plasma cutting operates 3 to 5 times faster than flame cutting, reducing lifting and repositioning operations, ultimately saving more than tenfold the processing time compared to traditional methods.

2.2 Superior Speed Compared to Flame Cutting

- When processing steel with a thickness of less than 30 mm, plasma cutting is approximately five times faster than oxy-fuel cutting, providing higher efficiency and better quality.

2.3 High Capability for Complex Bevel Processing

Traditional welding processes require vertical cutting followed by bevel preparation, increasing workload and precision challenges.

The CNC infinite rotary cutting system can automatically execute curved and variable-angle bevel cuts through pre-programmed paths, ensuring higher accuracy.

2.4 Cost Control and Green Production

- Traditional cutting methods are inefficient, costly, and labor-intensive.

- Plasma cutting, as the heat source of this system, provides higher speed, minimal heat-affected zones, reduced material deformation, and broader material adaptability.

- It reduces manual intervention, optimizes material utilization, and shortens production cycles while minimizing pollution, dust, and operator exposure to harmful residues.

3. Application in Bent and Twisted Structural Components at Yinchuan Airport

Our company undertook the steel structure project for the third phase of Yinchuan Hedong International Airport in 2015. The main terminal roof structure consists of wavy single-layer steel frames, featuring continuous variable-section box beams with forked arch columns.

The upper structure includes bent and twisted box components measuring (700–400) mm × 600 mm × 25 mm × 25 mm, with individual elements 7–9 meters long. Due to varying curvature in the arch columns, the web plates required multi-angle curved and gradient bevels, ranging from 10° to 40°, presenting a high degree of difficulty.

3.1 Traditional vs. Infinite Rotary Cutting Processing

- Traditional method: Required CNC flame cutting → Lifting → Marking → Semi-automatic beveling, leading to increased repositioning, excessive grinding, and longer work hours.

- Infinite rotary cutting: Eliminated lifting, marking, and grinding steps, with different bevel angles controlled by computer input, improving efficiency and precision while reducing manual labor costs.

3.2 Processing Efficiency Gains

4. Future Prospects for Infinite Rotary Cutting Technology

CNC cutting technology is evolving rapidly, driven by advancements in computing, numerical control, and cutting process optimization. The future of CNC cutting will emphasize intelligent, fast, and highly optimized manufacturing techniques, ensuring high efficiency, material conservation, and reduced energy consumption.

As China’s steel structure industry matures, an increasing number of innovative, high-quality projects are emerging, boosting industry growth. However, processing plants must enhance their capabilities to meet rising demands, particularly in high-strength steel cutting. The key challenge is to minimize thermal processing steps and preserve essential microelements in the base material.

The infinite rotary plasma cutting technology, with its exceptional processing advantages, will play a crucial role in advancing steel structure manufacturing, contributing to the development of smart factories and next-generation steel production solutions.