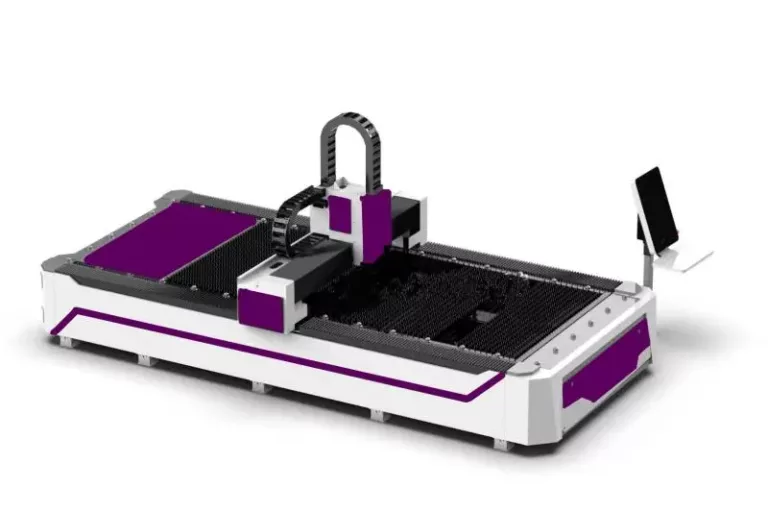

Air Duct Laser Cutting Machine: High-Efficiency HVAC Solution

The PCL Air Duct Laser Cutting Machine is engineered for the high-speed production of HVAC ductwork. By integrating a lightweight gantry system with specialized nesting software, it optimizes both cutting velocity and material efficiency for thin sheet metal fabrication.

This system is specifically optimized for galvanized steel and stainless steel, providing clean, burr-free edges that eliminate the need for secondary finishing processes.

Technical Specifications

| Working Area | 1500mm x 3000mm / 1500mm x 4000mm |

| Laser Power Source | 1000W - 3000W (Fiber Technology) |

| Max. Material Thickness | 0.5mm - 4.0mm (Ductwork Optimized) |

| Positioning Accuracy | ±0.03 mm |

| Control System | Professional CNC with Duct CAM Support |

| Cooling Mode | Dual-Circuit Water Cooling |

Core HVAC Advantages

- • Production Speed: Lightweight gantry allows for high acceleration on thin sheets.

- • Material Savings: Auto-nesting software reduces scrap by up to 15%.

- • Clean Finish: High-quality fiber laser source ensures ready-to-assemble edges.

- • Low Maintenance: Solid-state fiber laser requires minimal operational upkeep.

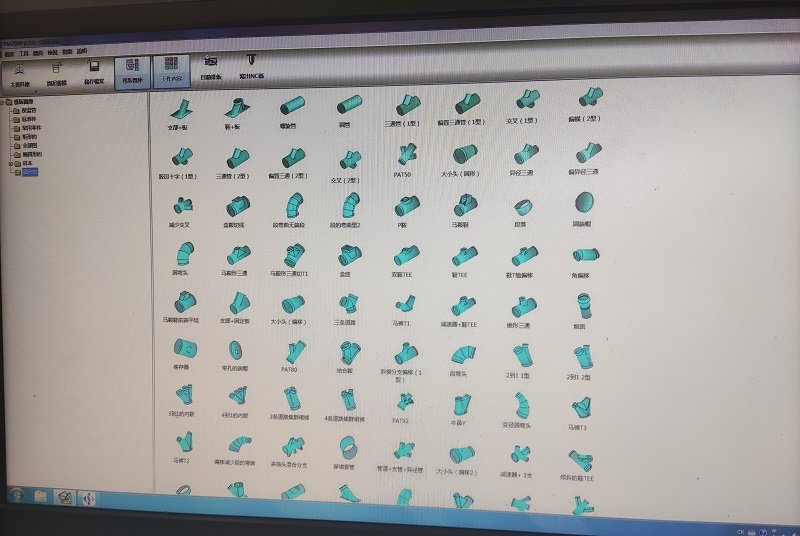

HVAC Ductwork Precision Cutting

Integrated ductwork nesting software for optimized production.

Automated unfolding and high-precision cutting results

air duct laser cutting machine is a specialized tool used for cutting and shaping metal sheets or other materials commonly used in air duct fabrication. The machine utilizes laser technology to achieve precise and efficient cutting with various benefits, including high cutting speeds, accuracy, and versatility.

the air duct laser cutting machine streamlines the fabrication process, reducing production time and improving the quality of air duct systems used in HVAC installations and industrial applications.

different roller can take different thickness coils

in order to laser cutting, level the coils to be steel plate

maxphotonics, raycus laser cutting system choose, 1000w-3000w