automatic h beam cutter

Model:

H300,H400,H600,H800,H1200

machine ability

0-30mm steel cutting, 0-20 stainless cutting

Cutting size

300-800mm

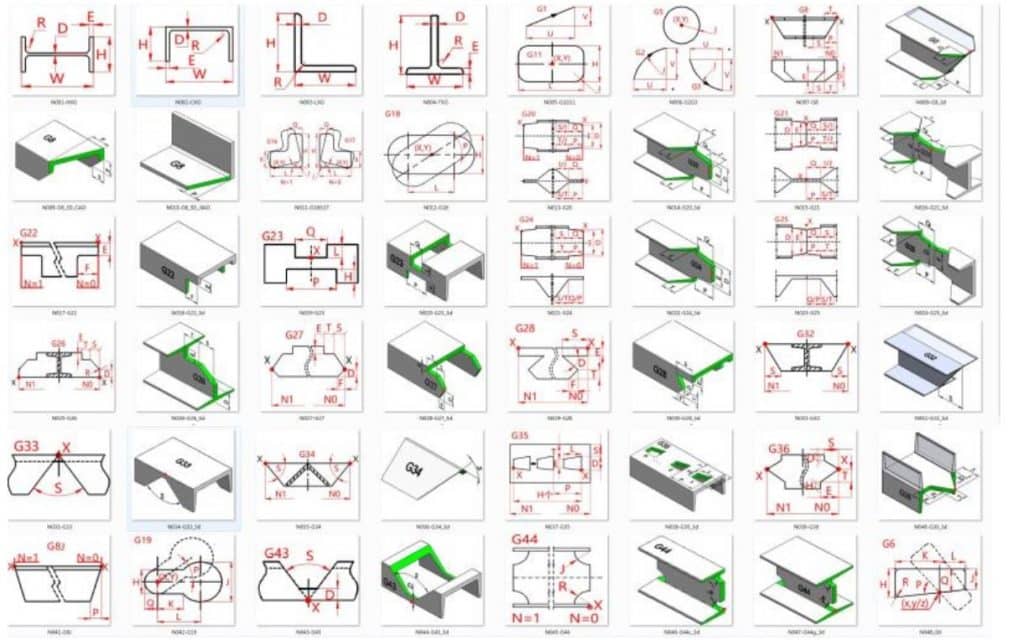

This Auto CNC H beam cutting machine provides H/L/C beam cutting solutions.Its control and programming software are based on Windows operating system. which can generate CNC codes from drawings and it save operators and engineers time. This square cutting machine is widely used in steel structure, construction, shipbuilding, offshore engineering, elevator manufacture, glass wall installation, bridge and tower construction, and heavy equipment industries. After adding moving axis on torch, our square cutting machine an cut all types of bevels for welding process. This machine can be customized to special specifications and applications

CNC H beam cutter model choose

Model | H300 | H400 | H600 | H800 | H1200 |

Max Width of beam | 300mm | 400mm | 600mm | 800mm | 1200mm |

Length choose | 6/12/15 meter | ||||

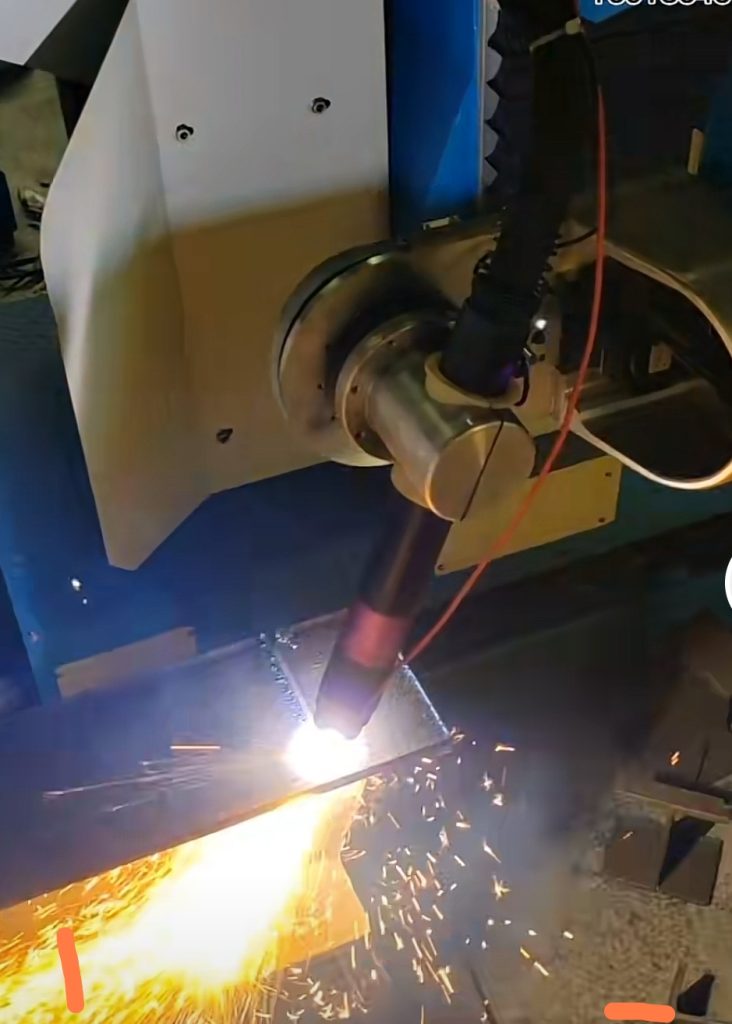

When using a plasma cutter to cut H beams, it is important to ensure that the torch is cutting through the material at the correct angle to achieve a clean and accurate cut. One way to achieve this is by using a bevel head or a tilting torch that can adjust the angle of the torch to match the angle of the H beam.

However, even with a bevel head or a tilting torch, it is still possible for the torch to cut into the web of the H beam if the torch height is not properly controlled. This can result in a poor quality cut and may even damage the machine or the workpiece.

To avoid this issue, some H beam plasma cutting machines are equipped with a TCP cutting head. The TCP cutting head is designed to automatically adjust the height of the torch based on the thickness of the material being cut and the angle of the cut. This ensures that the torch remains at the correct height throughout the cutting process, even if the angle of the cut changes.