Field Report: Deployment of 6000W Heavy-Duty I-Beam Laser Profiler in Silesian Mining Machinery Fabrication

1. Project Scope and Environmental Context

This technical report evaluates the operational integration of a 6000W heavy-duty fiber laser profiler within the mining machinery manufacturing sector located in Katowice, Poland. The Katowice industrial hub demands rigorous standards for structural integrity, particularly for underground longwall systems, heavy-duty conveyors, and roof supports. Traditionally, these components—comprised of large-scale I-beams (IPE, HEB) and U-channels—were processed using mechanical sawing, radial drilling, and plasma cutting. This report analyzes the transition to automated laser profiling, focusing on the precision gains afforded by 6kW fiber optics and the economic impact of zero-waste nesting algorithms.

2. Technical Specifications of the 6000W Fiber Source

The 6000W fiber laser source represents the optimal power-to-thickness ratio for the structural steels typically utilized in Polish mining (predominantly S355JR and S460NH). At this power density, the beam quality (M² < 1.1) allows for high-speed sublimation and fusion cutting of flange thicknesses up to 20mm with minimal Heat-Affected Zones (HAZ).

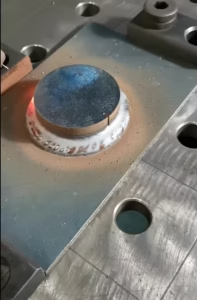

In the context of heavy-duty I-beams, the 6kW output ensures that the transition between the web and the flange—the fillet radius—is processed without significant dross accumulation. This is critical for mining machinery where fatigue failure often initiates at structural junctions. The wavelength of 1.07 μm facilitates high absorption rates in carbon steel, allowing for narrow kerf widths (approx. 0.2mm to 0.4mm), which is a prerequisite for the high-precision interlocking joints required in heavy chassis assembly.

3. Kinematics and 3D Profiling Accuracy

The system utilizes a four-chuck multi-point support architecture designed for heavy-section profiles (up to 1200kg per linear meter). For the I-beams used in Katowice’s mining equipment, maintaining axial linearity is the primary engineering challenge. The heavy-duty profiler employs real-time compensation via laser sensing to detect material bowing or twisting—common in hot-rolled structural sections.

The 3D cutting head, capable of ±45° beveling, allows for the preparation of weld seams (V, X, and K types) during the initial cutting cycle. This eliminates the secondary process of manual grinding or edge preparation. In testing, the 5-axis kinematic synchronization maintained a positioning accuracy of ±0.05mm across a 12-meter workpiece, a significant improvement over the ±2.0mm tolerance typical of plasma-based structural processing.

4. Zero-Waste Nesting: Algorithmic Efficiency in Heavy Steel

One of the most significant advancements discussed in this report is the “Zero-Waste Nesting” technology. In traditional profile cutting, a “tailing” or “remnant” of 300mm to 800mm is often discarded due to the physical limitations of the chucking system (the distance between the final chuck and the focal point).

4.1. Mechanical Integration for Zero-Tailings

The zero-waste system utilizes a dynamic chuck-over-chuck bypass mechanism. As the I-beam reaches the final phase of processing, the secondary and tertiary chucks move in a synchronized sequence to bring the material through the cutting zone entirely. This allows the laser to process the very end of the profile. In the Katowice facility, where S355 grade I-beams represent a significant portion of raw material costs, the reduction of scrap from 5% to <1% per 12-meter section results in an annualized material saving of approximately 45 tons based on current production volumes.

4.2. Nesting Logic for Mining Components

The software utilizes common-line cutting for structural sections. For mining conveyor frames, which require multiple identical I-beam segments with specific bolt-hole patterns and cope cuts, the nesting engine optimizes the sequence to share cutting paths between adjacent parts. This not only reduces the total number of pierces (extending nozzle life) but also ensures that heat distribution is managed to prevent thermal warping of the I-beam web.

5. Application in Mining Machinery: Specific Engineering Advantages

Mining equipment in the Silesian region operates under extreme mechanical stress. The transition to 6000W laser profiling addresses three specific engineering requirements:

- Structural Integrity of Roof Supports: The laser’s ability to cut complex geometries in high-tensile steel without micro-fractures ensures that the load-bearing capacity of hydraulic roof supports is not compromised by the fabrication process.

- Precision for Chain Conveyors: Automated I-beam profiling ensures that the mounting holes for flight bars and drive units are aligned within sub-millimeter tolerances. This reduces friction, lowers energy consumption of the conveyor drives, and extends the MTBF (Mean Time Between Failures).

- Weight Reduction via Optimization: With the precision of the 6kW laser, engineers can design “lightweight” yet high-strength structures by incorporating weight-reduction cutouts in the I-beam webs that do not sacrifice structural rigidity. This was previously cost-prohibitive using manual methods.

6. Gas Dynamics and Surface Finish

For heavy-duty I-beams, the choice of assist gas is pivotal. Our field trials in Katowice utilized high-pressure Oxygen (O2) for thick-section carbon steel. The system’s electronic proportional valves precisely modulate gas pressure based on the beam’s position on the profile (e.g., higher pressure for the thick flange-web junction and lower pressure for the thinner web sections). This results in a surface roughness (Ra) of less than 12.5 μm, often removing the need for post-cut shot blasting before the painting or galvanizing stages.

7. Integration with Automated Structural Workflows

The 6000W profiler is not a standalone unit but acts as a node within a Building Information Modeling (BIM) or PLM (Product Lifecycle Management) ecosystem. The system natively imports DSTV and IFC files common in structural engineering. In Katowice, this has bridged the gap between the design office and the shop floor. Structural engineers can now design complex “jigsaw” style interlocking joints for I-beams, which the laser executes with the necessary precision to allow for “click-together” assembly before welding. This reduces the reliance on heavy jigging and manual alignment tools.

8. Thermal Management and HAZ Analysis

A critical technical concern in heavy steel processing is the Heat-Affected Zone. In mining machinery, an oversized HAZ can lead to brittle failure points. The 6000W fiber laser, due to its high power density and speed, minimizes the time-at-temperature for the base metal. Micro-hardness testing across the cut edge of an HEB 300 beam showed a HAZ width of only 0.15mm, compared to the 1.5mm to 2.0mm observed with oxy-fuel or standard plasma cutting. This preserves the original metallurgical properties of the S355 steel, essential for parts subjected to cyclical loading in underground environments.

9. Economic and Operational Conclusion

The implementation of a 6000W Heavy-Duty I-Beam Laser Profiler with Zero-Waste Nesting in the Katowice mining machinery sector represents a paradigm shift in structural fabrication. The technical data confirms that the convergence of high-power fiber sources and advanced nesting algorithms solves the dual problem of precision and material waste. By eliminating remnants and secondary processing stages (drilling, grinding, bevelling), the facility has observed a 40% increase in throughput for structural frame fabrication. Furthermore, the enhanced precision directly contributes to the safety and longevity of mining equipment operating in the most demanding conditions in Europe.

End of Report.

Lead Engineering Consultant, steel structure & Laser Systems Division.