Optimizing Industrial Production: The 12kW Fiber laser cutting Machine for Aluminum Alloy

The transition toward high-power fiber laser technology has redefined the parameters of modern manufacturing. In industrial hubs like Leon, where automotive, aerospace, and structural engineering sectors demand high-precision components, the 12kW fiber laser cutting machine has emerged as a cornerstone of production efficiency. This guide explores the technical intricacies, operational advantages, and specific considerations for processing aluminum alloys using 12kW of laser power.

The Power of 12kW: Redefining Throughput

A 12kW fiber laser represents a significant leap in power density compared to standard 3kW or 6kW systems. In the context of laser cutting, power translates directly into speed and the ability to process thicker materials. For aluminum alloys, which are known for their high thermal conductivity and reflectivity, the additional wattage is not merely a luxury but a technical necessity for high-volume production. At 12,000 watts, the laser beam achieves a power density that can instantaneously vaporize aluminum, minimizing the heat-affected zone (HAZ) and ensuring a cleaner edge profile.

Material Challenges: Processing Aluminum Alloys

Aluminum alloys, such as the 5000 and 6000 series commonly used in Leon’s manufacturing plants, present unique challenges for laser cutting. Aluminum reflects a significant portion of laser energy, especially in its solid state. Early fiber lasers struggled with back-reflection, which could damage the resonator. However, modern 12kW systems are equipped with advanced optical isolators and beam delivery systems designed to handle high-reflectivity materials safely.

Furthermore, aluminum’s high thermal conductivity means that heat dissipates rapidly away from the cut zone. A lower-power laser might struggle to maintain a consistent melt pool, leading to excessive dross (slag) on the underside of the workpiece. The 12kW fiber laser overcomes this by delivering energy faster than the material can conduct it away, resulting in a narrow kerf and a superior surface finish.

Technical Specifications and Performance Metrics

When deploying a 12kW laser cutting system for aluminum, engineers must consider the specific performance metrics that define the machine’s capability. In Leon’s competitive industrial environment, these metrics dictate the cost-per-part and overall project viability.

Cutting Thickness and Speed

A 12kW system is capable of cutting aluminum alloy plates up to 40mm or even 50mm in thickness, though the “sweet spot” for high-speed production typically lies between 3mm and 25mm. For instance, while a 6kW machine might cut 6mm aluminum at 8-10 meters per minute, a 12kW system can double that speed, significantly reducing cycle times. This throughput is vital for industries in Leon that supply parts to just-in-time (JIT) automotive assembly lines.

Assist Gas Selection: Nitrogen vs. Oxygen vs. Air

The choice of assist gas is critical when laser cutting aluminum. Nitrogen is the industry standard for high-quality finishes, as it acts as a shielding gas to prevent oxidation of the cut edge. This is essential for parts that require subsequent welding or painting. With 12kW of power, high-pressure nitrogen can be used to “blow” the molten aluminum out of the kerf, leaving a burr-free edge. In some cost-sensitive applications, compressed air can be used for thinner gauges, though it may result in a slight oxide layer.

The Leon Industrial Context: Why 12kW Matters

Leon has established itself as a region with a robust appetite for advanced manufacturing technology. The local economy’s reliance on metal fabrication means that staying competitive requires the latest in laser cutting technology. By adopting 12kW systems, local fabricators can handle a wider range of contracts, from thin-gauge decorative panels to heavy-duty structural components for the transport sector.

The integration of fiber laser technology also aligns with sustainability goals. Fiber lasers are significantly more energy-efficient than older CO2 technology, converting a higher percentage of electrical wall-plug power into laser light. For a facility in Leon operating multiple shifts, the reduction in electricity consumption and the elimination of laser gases (used in CO2 resonators) represent a substantial reduction in the carbon footprint and operational costs.

Advanced Features of High-Power Fiber Lasers

Modern 12kW machines are more than just raw power; they are sophisticated CNC platforms. Key features that enhance the laser cutting process for aluminum include:

Auto-Focus Cutting Heads

Because the optimal focal point changes based on material thickness and type, 12kW machines utilize automated cutting heads. These heads adjust the lens position in milliseconds, ensuring that the beam is always perfectly focused for the cleanest possible cut. This is particularly important for aluminum, where the focus must be precisely maintained to manage the material’s high reflectivity.

Nozzle Cleaning and Changeover

High-power cutting generates significant heat and potential splatter. Automated nozzle cleaning systems ensure that the nozzle remains free of debris, which is critical for maintaining beam quality. Furthermore, automatic nozzle changers allow the machine to switch between different nozzle diameters for different material thicknesses without manual intervention, maximizing “green light” time.

Real-Time Monitoring and Piercing Sensors

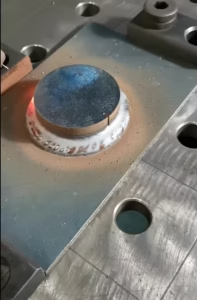

Piercing thick aluminum can be a violent process. 12kW systems often feature sensors that monitor the pierce in real-time. Once the sensor detects that the beam has successfully penetrated the plate, the machine immediately transitions to the cutting motion. This prevents excessive heat buildup and protects the optics from back-splatter.

Maintenance and Longevity in a 12kW Environment

Maintaining a 12kW fiber laser cutting machine requires a disciplined approach to ensure longevity and consistent performance. The high power levels place significant stress on the optical components. Regular inspection of the protective windows (cover slips) is mandatory, as even a tiny speck of dust can be vaporized by the 12kW beam, potentially damaging the focus lens.

The cooling system, or chiller, is another critical component. A 12kW laser generates substantial heat within the resonator and the cutting head. The chiller must maintain a precise temperature range to ensure the stability of the laser wavelength and to protect the internal electronics. In the climate of Leon, ensuring the chiller is properly sized for ambient temperatures is essential for uninterrupted summer operation.

Economic Impact: Return on Investment (ROI)

While the initial capital expenditure for a 12kW fiber laser is higher than lower-power alternatives, the ROI is often realized much faster due to the increased production capacity. In a high-demand market like Leon, the ability to process twice as many parts per hour allows a shop to take on more work without increasing its footprint or labor force.

Furthermore, the edge quality produced by a 12kW laser often eliminates the need for secondary finishing processes like grinding or deburring. For aluminum alloys, which can be labor-intensive to finish manually, this represents a significant saving in labor costs and a reduction in the overall lead time for the end customer.

Future-Proofing Your Fabrication Business

As the industry moves toward “Industry 4.0,” 12kW fiber laser cutting machines are increasingly integrated into networked environments. These machines provide data on gas consumption, power usage, and cutting time, allowing managers in Leon to optimize their workflows with precision. The high power of the 12kW source also ensures that the machine remains relevant as material science evolves and new, more challenging aluminum alloys are introduced to the market.

Conclusion

The 12kW fiber laser cutting machine is a transformative tool for the aluminum alloy fabrication industry in Leon. By combining raw power with sophisticated control systems, it addresses the inherent challenges of processing aluminum, offering unprecedented speed, precision, and reliability. For manufacturers looking to lead in a competitive global market, investing in high-power laser cutting technology is not just an upgrade—it is a strategic necessity that paves the way for future growth and innovation.