Introduction: The Engineering Paradigm Shift in High-Power Laser Processing

As a Senior Mechanical Engineer at PCL Group, I have witnessed the rapid evolution of fiber laser technology, transitioning from the standard 6kW and 12kW benchmarks to the current industrial frontier: the 40kW ultra-high-power threshold. In the context of Mexico City’s burgeoning infrastructure and elevator manufacturing sector, the implementation of a 40kW Tube Laser Cutter represents more than just an upgrade in speed—it is a fundamental shift in structural integrity and production efficiency. This technical analysis explores the synergy between high-wattage fiber sources and the specialized requirements of galvanized steel fabrication, specifically tailored for the demanding environmental and electrical conditions of the Mexican industrial landscape.

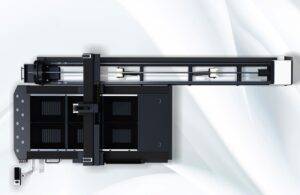

Structural Foundation: Tube-Welded Standard Bed and 600°C Annealing

The Physics of Stability at 40kW

When operating at 40kW, the kinetic energy generated by high-speed gantry movements and the thermal energy dissipated by the laser source necessitate a machine bed of unparalleled stability. PCL Group utilizes a heavy-duty tube-welded standard bed, engineered to withstand the dynamic loads associated with 2G-3G acceleration. The structural integrity of this bed is achieved through a rigorous 600°C stress-relief annealing process. This thermal treatment is critical; it eliminates internal residual stresses within the carbon steel frame that are naturally induced during the welding process. Without this annealing, the bed would be subject to micro-deformations over time, compromising the ±0.03mm positioning accuracy required for elevator component manufacturing.

Vibration Dampening and Long-Term Precision

The high-density triangular structure of the welded bed provides superior vibration dampening compared to lighter aluminum or cast-iron alternatives. In the high-altitude environment of Mexico City, where atmospheric pressure can affect thermal dissipation, the mass of the PCL bed acts as a thermal sink, maintaining a consistent temperature across the linear guides. This prevents thermal expansion from affecting the pitch of the rack and pinion system, ensuring that even after 10 years of continuous 24/7 operation, the machine maintains its “factory-new” geometric tolerances.

Control Systems: The Precision of EtherCAT Integration

Real-Time Communication Protocols

At the heart of the PCL 40kW system is the EtherCAT (Ethernet for Control Automation Technology) control architecture. Unlike traditional pulse-based systems, EtherCAT offers a distributed control mechanism with nanosecond-level synchronization between the CNC controller, the laser source, and the servo drives. This is particularly vital when cutting complex tube geometries for elevator frames, where the synchronization of the chuck rotation (W-axis) and the cutting head movement (X/Y/Z-axis) must be flawless to prevent “kerf-widening” or “corner-burn.”

Adaptive Power Control

The EtherCAT system allows for real-time laser power modulation. As the cutting head approaches a sharp corner on a square galvanized tube, the system automatically adjusts the 40kW output in correlation with the feed rate. This prevents excessive heat accumulation in the zinc coating, ensuring a clean, burr-free finish that requires no secondary grinding. For the elevator industry, where aesthetic finish and structural safety are paramount, this level of control is non-negotiable.

Processing Galvanized Steel: The 40kW Nitrogen Advantage

Overcoming the Zinc Barrier

Galvanized steel presents a unique challenge: the zinc coating has a significantly lower melting point than the underlying steel. When using lower power lasers (under 12kW), the zinc often vaporizes and interferes with the laser beam, leading to dross and slag. However, the 40kW fiber source provides such high energy density that it achieves “high-speed sublimation cutting.” By utilizing high-pressure Nitrogen (N2) as the assist gas, we create an inert environment that blows away the molten material before it can oxidize or bond to the cut edge.

Superior Edge Quality for Elevator Components

In elevator manufacturing, components like guide rail brackets and door frames must be resistant to corrosion. Oxygen cutting leaves an oxide layer that must be removed before painting or welding. By using 40kW power with Nitrogen, the resulting edge is bright, clean, and retains the integrity of the galvanized layer near the cut. This significantly reduces labor costs and increases the throughput of the Mexico City production facility. Furthermore, the 40kW power allows for the processing of thick-walled tubes (up to 25mm-30mm) at speeds that were previously only possible on thin-gauge materials.

Regional Engineering: Navigating Mexico City’s Power Grid

The Necessity of Industrial Voltage Regulators

One of the most critical technical considerations for deploying a 40kW laser in Mexico City is the stability of the local electrical grid. Industrial zones in the Valley of Mexico often experience voltage fluctuations, sags, and harmonic distortions. A 40kW fiber laser source is a highly sensitive optoelectronic component; even a 5% deviation in voltage can lead to unstable beam quality or, in worst-case scenarios, catastrophic failure of the laser diodes. PCL Group mandates the installation of a high-precision, heavy-duty Industrial Voltage Regulator (AVR) with every 40kW installation. This ensures a constant 380V/480V supply, shielding the machine’s sophisticated electronics from the “dirty power” common in the region.

Environmental Adaptation

At an elevation of 2,240 meters, Mexico City’s air is thinner, which affects the cooling efficiency of standard chillers. PCL’s engineering team specifies oversized, dual-circuit cooling systems for these installations. These chillers are designed to maintain the laser source and the cutting head at a constant 22°C, regardless of the ambient altitude or temperature fluctuations. This ensures that the 40kW output remains stable during long production cycles, preventing “thermal drift” in the beam’s focal point.

PCL Group’s Commitment: On-site Installation and Technical Support

Professional Deployment in Mexico

The complexity of a 40kW tube laser requires more than just a delivery; it requires a comprehensive engineering deployment. PCL Group provides on-site installation by a team of specialized field engineers who speak the local language and understand the specific industrial standards of Mexico (NOM). Our installation process includes precision leveling using interferometric lasers, calibration of the EtherCAT bus, and rigorous testing of the Nitrogen gas delivery system to ensure leak-free operation at high pressures (up to 25 bar).

Operator Training and Lifecycle Management

Beyond the hardware, we provide intensive training for local operators. This covers the nuances of 40kW cutting parameters, preventive maintenance for the tube-welded bed, and software optimization for nested tube cutting. By empowering the local workforce with this high-level technical knowledge, we ensure that the elevator manufacturers in Mexico City can maximize their Return on Investment (ROI) and maintain a competitive edge in the global market. Our local service hubs ensure that spare parts—from protective windows to ceramic rings—are available within 24 hours, minimizing downtime in high-stakes production environments.

Conclusion: The Future of Industrial Fabrication

The integration of a PCL 40kW Tube Laser Cutter into the Mexico City industrial sector is a testament to the power of precision engineering. By combining a 600°C annealed tube-welded bed, the lightning-fast response of EtherCAT control, and the raw processing power of a 40kW source, we provide a solution that transcends traditional manufacturing limits. For the elevator industry, this means faster production of galvanized structural components, lower cost-per-part, and a level of quality that meets the highest international safety standards. As we continue to push the boundaries of what is possible in laser technology, PCL Group remains dedicated to providing the robust, reliable, and high-performance machinery that modern industry demands.