Field Technical Report: Integration of 6000W Laser Profiling in Ho Chi Minh City Steel Fabrication

1. Project Overview and Environmental Context

This report details the operational deployment and performance metrics of the Heavy-Duty I-Beam Laser Profiler (6000W Fiber Source) at our primary fabrication facility in the Hiep Phuoc Industrial Park, Ho Chi Minh City. As the structural steel industry in Vietnam shifts toward high-rise and complex infrastructure, the traditional reliance on manual oxy-fuel cutting and plasma arcs has reached its limit regarding precision and throughput.

The implementation of high-wattage Laser Technology in the HCMC region presents unique challenges, primarily the high ambient humidity (averaging 75-80%) and fluctuating power grid stability. This report evaluates how the profiler bridges the gap between raw beam processing and high-integrity Steel welding, focusing on the synergy of automated geometry preparation.

2. The Heavy-Duty I-Beam Laser Profiler: Mechanical Architecture

The unit under review is a multi-axis 3D laser cutting system designed specifically for large-scale structural sections. Unlike flatbed lasers, this profiler utilizes a rotating chuck system and a 5-axis robotic head to navigate the flanges and webs of I-beams, H-beams, and channels up to 12,000mm in length.

2.1 Power Calibration and Beam Quality

We opted for the 6000W resonator to handle flange thicknesses up to 25mm with a clean cut. In our HCMC workshop, we found that at 6000W, we achieve a “glance” finish on Q355B steel, which significantly reduces the post-process cleaning time. The Laser Technology utilized here relies on a focused fiber delivery system, which maintains a kerf width of less than 0.2mm—a feat impossible with plasma systems.

2.2 Material Handling in HCMC Constraints

Space in HCMC industrial zones is at a premium. The Heavy-Duty I-Beam Laser Profiler integrates loading and unloading into a linear footprint. We observed that the automated centering sensors are critical; the beams we receive from regional mills often have slight camber or sweep. The profiler’s ability to “touch-sense” the actual beam geometry and adjust the cutting path in real-time ensures that bolt holes and weld preparations remain co-linear across a 12-meter span.

3. Synergizing Laser Technology with Structural Requirements

The primary advantage of Laser Technology in this context is the minimization of the Heat Affected Zone (HAZ). In senior structural engineering, we worry about the micro-structural changes at the cut edge which can lead to brittle fractures under cyclic loading.

3.1 Precision Beveling for Weld Preparation

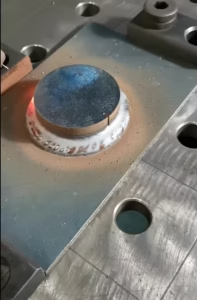

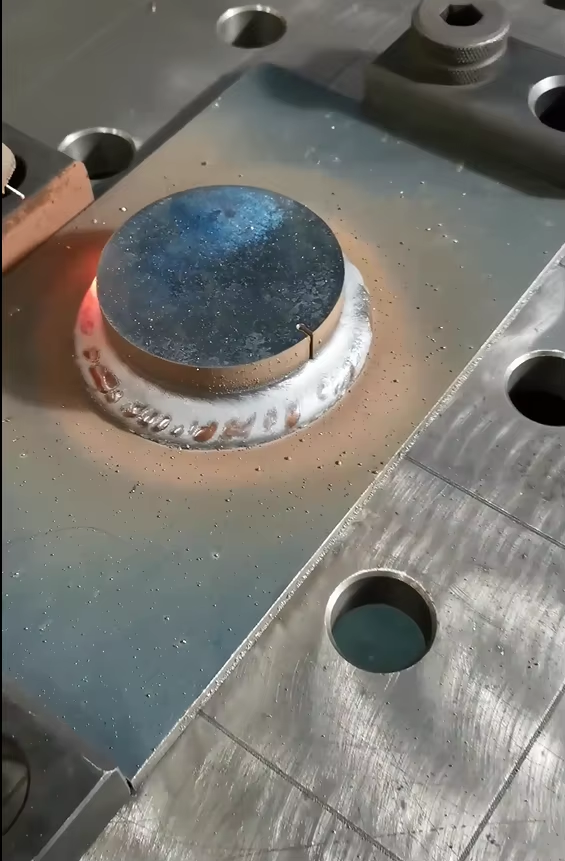

The 5-axis head allows for complex bevels (V, X, and K shapes). Traditionally, these were ground manually by technicians in HCMC, leading to inconsistent root gaps. The Heavy-Duty I-Beam Laser Profiler executes these bevels with ±0.5mm accuracy. This precision is the foundation for high-quality Steel welding. When the root gap is consistent, the welder—or the welding robot—can maintain a steady travel speed and voltage, resulting in full-penetration welds with minimal porosity.

3.2 Thermal Management

Despite the 6000W output, the concentrated energy density of the laser means the total heat input into the beam is lower than oxy-fuel. This prevents the “twisting” of I-beams during cutting, ensuring that when the beam reaches the assembly jig, it sits flush without the need for hydraulic straightening.

4. Impact on Downstream Steel Welding Operations

The integration of the Heavy-Duty I-Beam Laser Profiler has fundamentally changed our Steel welding protocol. The quality of a weld is 70% preparation and 30% execution. By automating the preparation phase, we have eliminated the most common variable in weld failure: poor fit-up.

4.1 Root Gap Consistency

In structural Steel welding, a variable root gap leads to “blow-through” or “lack of fusion.” Because the laser profiler cuts with such high repeatability, our welders now report a 40% increase in arc-on time. They are no longer “filling holes” caused by poor plasma cuts; they are laying beads on machine-matched surfaces.

4.2 Surface Chemistry and Weld Adhesion

One lesson learned in the HCMC facility: the assist gas used during the Laser Technology process (Oxygen vs. Nitrogen) significantly impacts the subsequent Steel welding. While Oxygen is faster for thick sections, it leaves a thin oxide layer. For our high-spec projects, we have switched to Nitrogen or high-pressure Air cutting to ensure the weld pool achieves maximum wetting without the need for mechanical wire brushing.

5. Operational Lessons Learned from the HCMC Workshop

After six months of operating the Heavy-Duty I-Beam Laser Profiler, several field-specific insights have emerged that were not in the manufacturer’s manual.

5.1 Humidity and Optics

The HCMC climate is brutal on optical components. We had to upgrade the chiller system and install a dedicated industrial dehumidifier for the laser source room. Moisture in the beam path can cause “thermal lensing,” where the laser loses focus, leading to dross buildup on the bottom of the I-beam flange. This dross is detrimental to Steel welding, as it introduces carbon impurities into the weld toe.

5.2 Beam Quality Variation

Regional steel supplies in Southeast Asia can have varying levels of surface rust or mill scale. We found that the Heavy-Duty I-Beam Laser Profiler requires a “pre-scan” pass on heavily oxidized beams to ensure the height sensor doesn’t crash. This adds 30 seconds to the cycle time but saves the cutting head from costly repairs.

6. Quantitative Performance Analysis

To justify the capital expenditure of Laser Technology in our HCMC operations, we tracked the following metrics over a 90-day period:

- Production Speed: A standard 400mm I-beam with 12 bolt holes and four 45-degree cope cuts took 22 minutes manually. The laser profiler completes this in 3 minutes and 15 seconds.

- Consumable Cost: While the initial cost of laser nozzles and lenses is higher than plasma electrodes, the longevity of the fiber source (rated for 100,000 hours) provides a lower cost-per-meter in the long run.

- Weld Repair Rate: Our Ultrasonic Testing (UT) failure rate on Steel welding joints dropped from 4.2% to 0.8% due to the elimination of edge irregularities and improved fit-up.

7. Engineering Conclusion

The deployment of the Heavy-Duty I-Beam Laser Profiler in Ho Chi Minh City represents a necessary evolution for our structural steel operations. The synergy between high-wattage Laser Technology and downstream Steel welding processes cannot be overstated. By treating the cutting phase as a high-precision machining operation rather than a “rough cut,” we have drastically reduced labor costs and improved the structural integrity of our builds.

For future deployments, I recommend a heavy focus on the environmental control systems (chillers and air dryers) to suit the HCMC climate and a transition toward Nitrogen-assist cutting to further streamline the welding workflow. The era of the manual grinder in heavy fabrication is coming to a close; the precision of the laser is now the standard.

End of Report

Prepared by: Senior Structural Engineer

Location: HCMC Field Office

Date: October 2023