Introduction: The Evolution of High-Power laser cutting

The industrial landscape is undergoing a radical transformation, driven by the rapid advancement of fiber laser technology. Among the most significant breakthroughs in recent years is the emergence of the 40kW fiber laser cutting machine. This level of power represents a paradigm shift in how heavy-duty materials are processed, moving beyond the limitations of plasma and traditional mechanical cutting methods. In industrial hubs like Leon, where manufacturing, automotive, and aerospace sectors demand high precision and rapid throughput, the 40kW fiber laser has become a cornerstone of modern production lines.

Laser cutting at 40kW provides an unprecedented combination of speed, accuracy, and thickness capacity. For decades, aluminum alloys were considered challenging for fiber lasers due to their high reflectivity and thermal conductivity. However, the sheer energy density of a 40kW beam overcomes these physical barriers, allowing for clean, high-speed separation of even the thickest aluminum plates. This guide explores the technical intricacies, operational advantages, and strategic importance of implementing 40kW laser cutting technology for aluminum alloy fabrication in the Leon region.

The Physics of 40kW Laser Cutting on Aluminum Alloys

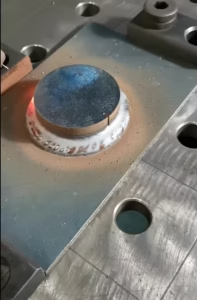

Aluminum alloys, such as the 5000 and 6000 series commonly used in structural engineering and transport, possess unique physical properties that dictate how they interact with laser energy. Aluminum is highly reflective at the 1.06-micron wavelength typical of fiber lasers. At lower power levels, this reflectivity can cause “back-reflection,” potentially damaging the laser source. However, 40kW systems utilize advanced optical isolators and high-density energy to “punch through” the reflective surface almost instantaneously, establishing a stable keyhole for the cutting process.

Furthermore, aluminum’s high thermal conductivity means that heat dissipates quickly from the cutting zone. In lower-power applications, this leads to a larger heat-affected zone (HAZ) and potential dross formation. With 40kW of power, the cutting speed is so high that the heat has less time to conduct into the surrounding material. The result is a narrower kerf, minimal thermal distortion, and a superior edge finish that often eliminates the need for secondary deburring or grinding processes.

Overcoming Material Thickness Barriers

One of the primary reasons manufacturers in Leon are upgrading to 40kW systems is the ability to process thick-section aluminum. While a 10kW or 20kW machine might struggle with aluminum plates over 30mm, the 40kW variant can comfortably process thicknesses up to 100mm and beyond, depending on the alloy and gas setup. This capability allows the laser cutting machine to compete directly with waterjet and plasma cutting, offering significantly faster cycle times and better dimensional tolerances.

Strategic Implementation in Leon’s Industrial Sector

Leon has established itself as a critical node in the global supply chain, particularly for the automotive and heavy machinery industries. The integration of 40kW laser cutting technology into Leon’s local factories provides a competitive edge in several ways. Firstly, the local availability of high-capacity laser processing reduces the need to outsource thick-plate cutting to other regions, shortening lead times and reducing logistics costs.

In the context of Leon’s growing aerospace interests, the precision of 40kW fiber lasers is vital. Aerospace-grade aluminum alloys, like 7075, require precise thermal control to maintain their structural integrity. The high-speed processing of 40kW systems ensures that the metallurgical properties of the alloy are preserved, meeting the stringent safety and quality standards required by the aviation industry. By adopting these high-power systems, Leon-based fabricators can position themselves as Tier-1 suppliers for international projects.

Energy Efficiency and Operational Costs

While the initial capital expenditure for a 40kW laser cutting machine is higher than that of lower-power units, the cost-per-part is significantly lower in high-volume environments. The 40kW laser operates with higher wall-plug efficiency than older CO2 lasers, and because it cuts so much faster, the energy consumed per meter of cut is reduced. In Leon, where energy costs are a constant consideration for industrial facilities, the efficiency of fiber laser technology provides a sustainable path toward increased production capacity.

Technical Specifications: Speed and Gas Dynamics

The performance of a 40kW laser cutting machine is not solely dependent on raw power; it is also a function of gas dynamics and motion control. When cutting aluminum alloy, the choice of assist gas—typically Nitrogen, Oxygen, or Compressed Air—plays a decisive role in the quality of the cut. For 40kW systems, Nitrogen is often the preferred choice for aluminum, as it provides an inert environment that prevents oxidation, resulting in a bright, weld-ready edge.

At 40kW, the flow rates and pressures of the assist gas must be meticulously controlled. Advanced cutting heads used in these machines feature auto-focusing capabilities and high-pressure nozzles designed to clear molten aluminum from the kerf at supersonic speeds. This prevents “dross” (hardened melt) from adhering to the bottom of the plate. In Leon’s fabrication shops, the ability to switch between gas types and optimize pressures via CNC software allows operators to transition seamlessly between thin-sheet high-speed cutting and thick-plate precision cutting.

Cutting Speed Comparisons

To illustrate the leap in performance, consider 20mm thick aluminum alloy. A 12kW laser might cut this at approximately 1.5 to 2.0 meters per minute. A 40kW laser cutting machine can achieve speeds exceeding 6 to 8 meters per minute for the same material. This 4x increase in throughput allows a single 40kW machine to replace multiple lower-power units, optimizing floor space and reducing labor requirements in the production facility.

Maintenance and Longevity of High-Power Systems

Operating a 40kW laser cutting machine in an industrial environment like Leon requires a disciplined approach to maintenance. The extreme power levels place significant stress on the optical components, particularly the protective windows and the focusing lens. Modern 40kW systems are equipped with real-time monitoring sensors that track the temperature and cleanliness of the optics. If contamination is detected, the system alerts the operator or shuts down to prevent catastrophic “thermal runaway” damage.

Dust extraction is another critical factor when processing aluminum alloy. Aluminum dust is highly flammable and can be explosive in certain concentrations. Therefore, 40kW machines must be paired with high-capacity, explosion-proof dust collectors. For businesses in Leon, adhering to local safety regulations regarding particulate matter and fire safety is essential. Regular cleaning of the slats, lubrication of the linear guides, and calibration of the laser source ensure that the machine maintains its micron-level precision over a service life of 100,000+ hours.

The Role of Software and Automation

The full potential of 40kW laser cutting is realized through advanced nesting software and automation. Because the machine cuts so quickly, manual loading and unloading become bottlenecks. Many facilities in Leon are now integrating automated pallet changers and robotic sorting systems. These systems work in tandem with the CNC controller to ensure that the machine is cutting for the maximum possible percentage of the shift. Smart nesting algorithms also minimize material waste, which is particularly important given the fluctuating price of aluminum alloy in global markets.

Future Outlook: Leon as a Technological Hub

The adoption of 40kW fiber laser technology is more than just an equipment upgrade; it is a signal of Leon’s commitment to “Industry 4.0.” As these machines become more integrated with IoT (Internet of Things) platforms, manufacturers can track performance metrics, predict maintenance needs, and optimize supply chains in real-time. The data generated by a 40kW laser cutting machine provides insights into production bottlenecks and material utilization that were previously unavailable.

Looking forward, we can expect to see even higher power levels, but 40kW currently represents the “sweet spot” for most heavy industrial aluminum applications. It offers the necessary force to tackle thick plates while maintaining the agility needed for complex geometries. For engineers and factory owners in Leon, investing in 40kW fiber laser technology is a strategic move that ensures long-term viability in an increasingly competitive global market.

Conclusion

The 40kW fiber laser cutting machine is a transformative tool for the processing of aluminum alloy. Its ability to combine extreme power with surgical precision makes it the ideal solution for Leon’s diverse industrial landscape. By understanding the physics of high-power laser interaction, optimizing gas dynamics, and embracing automation, manufacturers can achieve unprecedented levels of productivity. As the demand for lightweight, high-strength aluminum components continues to grow in the automotive and aerospace sectors, the 40kW laser stands ready to meet the challenge, driving the next generation of industrial excellence in Leon.