Mastering 30kW Fiber laser cutting for Aluminum Alloys in Toluca’s Industrial Sector

The industrial landscape of Toluca, State of Mexico, has undergone a rapid transformation over the last decade. As a primary hub for automotive, aerospace, and heavy machinery manufacturing, the demand for precision and throughput has never been higher. Central to this evolution is the adoption of ultra-high-power fiber laser technology. Specifically, the 30kW fiber laser cutting machine has emerged as a definitive tool for processing non-ferrous metals, particularly aluminum alloys, which are notorious for their challenging thermal and reflective properties.

In an environment where Tier 1 and Tier 2 suppliers must meet rigorous international standards, the 30kW threshold represents more than just raw power; it represents the ability to maintain edge quality at speeds that were previously unthinkable. For engineers and facility managers in Toluca, understanding the synergy between this high-wattage output and the metallurgical characteristics of aluminum is essential for maintaining a competitive edge in the global supply chain.

The Technical Superiority of 30kW Fiber Laser Power

The transition from 10kW or 12kW systems to 30kW is not merely incremental. In the realm of laser cutting, power correlates directly with the energy density available at the focal point. For aluminum alloys, which possess high thermal conductivity and high reflectivity, energy density is the critical factor in overcoming the material’s initial resistance to the beam.

A 30kW fiber laser cutting machine utilizes a sophisticated array of laser modules combined into a single high-brightness beam. This allows for a significantly smaller spot size even at high power levels. The result is a narrower kerf width and a much smaller Heat-Affected Zone (HAZ). For Toluca-based manufacturers producing structural components for the automotive industry, a reduced HAZ means the mechanical properties of the aluminum—such as tensile strength and fatigue resistance—remain uncompromised near the cut edge.

Challenges and Solutions in Aluminum Alloy Cutting

Aluminum alloys, such as the 5000, 6000, and 7000 series commonly used in Mexican manufacturing, present unique challenges. Aluminum reflects a significant portion of the laser’s infrared radiation, especially in its solid state. In lower-power machines, back-reflection can damage the resonator. However, modern 30kW systems are equipped with advanced back-reflection isolation technologies and sensors that monitor the beam path in real-time.

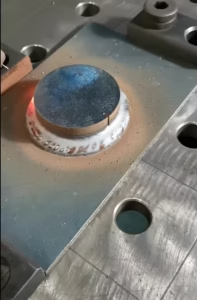

Furthermore, the high thermal conductivity of aluminum means that heat dissipates quickly from the cut zone. A 30kW laser overcomes this by delivering energy faster than the material can conduct it away. This “high-speed vaporization” leads to a cleaner melt-ejection process. When combined with high-pressure nitrogen as an assist gas, the 30kW laser produces a dross-free finish on aluminum plates up to 30mm or 50mm thick, which was previously the exclusive domain of plasma cutting or waterjet, albeit at much slower speeds.

Toluca: A Strategic Hub for High-Tech Fabrication

Toluca’s proximity to Mexico City and its established infrastructure makes it a strategic location for high-tech fabrication centers. The local workforce has evolved alongside the technology, moving from traditional machining to CNC-based fiber laser operation. The implementation of a 30kW fiber laser cutting machine in a Toluca facility allows for a massive consolidation of the production line. Where three 6kW machines were once needed to meet a quota, a single 30kW unit can often exceed that output while occupying a smaller footprint.

Moreover, the energy efficiency of fiber lasers is a significant factor for Mexican industries facing fluctuating energy costs. Fiber lasers convert electrical energy into light more efficiently than CO2 lasers, and the sheer speed of 30kW cutting means the “power-per-part” ratio is significantly lower, leading to better profit margins for local job shops and OEMs.

Optimizing Parameters for Different Aluminum Series

Successful laser cutting of aluminum in a 30kW environment requires meticulous parameter management. Each alloy series reacts differently to the beam:

1. 5000 Series (Magnesium Alloys)

Commonly used in marine and chemical applications, these alloys have excellent corrosion resistance. The 30kW laser allows for incredibly fast processing of 5083 or 5052 aluminum. Because magnesium has a lower boiling point than aluminum, the 30kW beam must be tuned to prevent excessive vaporization, which can lead to a slightly wider kerf if not managed with precise nozzle height control.

2. 6000 Series (Silicon and Magnesium Alloys)

The workhorse of the Toluca automotive sector, 6061 and 6063 alloys are favored for their structural integrity. These alloys are prone to “hot cracking” if the cooling rate is too slow. The 30kW laser cutting process is so rapid that the cooling rate is optimized, effectively bypassing the temperature ranges where cracking typically occurs. Engineers should focus on nitrogen pressure settings to ensure the molten silicon is ejected instantly.

3. 7000 Series (Zinc Alloys)

Used heavily in aerospace components, these are the strongest aluminum alloys. They are also the most sensitive to heat. The high power of a 30kW system allows for “cold-cutting” (high-speed cutting where the bulk material stays cool), which is vital for maintaining the T6 temper of 7075 aluminum. Precision in focal position—often slightly below the surface—is key here to ensure a vertical edge profile.

The Role of Assist Gases in High-Power Cutting

In the laser cutting of aluminum, the choice of assist gas is as important as the power of the laser itself. For a 30kW machine, nitrogen is the standard. Nitrogen acts as a mechanical force to blow the molten metal out of the kerf while preventing oxidation. Because aluminum oxidizes instantly when exposed to air at high temperatures, using oxygen would result in a heavily scaled, brittle edge that requires secondary finishing.

In Toluca’s industrial parks, many facilities are now installing large-scale nitrogen generation systems or liquid nitrogen tanks to keep up with the consumption rates of a 30kW machine. At high speeds, the gas pressure must be consistent (often between 15 and 20 bar) to ensure that the bottom of the cut remains clean. Any fluctuation in gas flow can lead to “bearding” or dross at the bottom of the aluminum plate, which negates the speed advantages of the 30kW system.

Maintenance and Safety for 30kW Systems

Operating a 30kW fiber laser cutting machine requires a rigorous maintenance schedule, specifically regarding the optical path. At 30,000 watts, even a microscopic speck of dust on the protective window can absorb enough energy to shatter the lens in milliseconds. In Toluca’s often dusty industrial environments, pressurized, filtered clean rooms for the cutting head are highly recommended.

Safety protocols must also be scaled up. A 30kW laser is a Class 4 radiation hazard. The housing of the machine must be fully enclosed with laser-safe glass (OD6+ or higher) rated for the specific wavelength of the fiber laser (typically around 1070nm). Furthermore, the filtration system (dust collector) must be high-capacity. Cutting aluminum produces fine aluminum oxide dust, which is not only a respiratory hazard but also potentially explosive if allowed to accumulate in high concentrations.

Economic Impact and ROI in the Mexican Market

For a manufacturing plant in Toluca, the return on investment (ROI) for a 30kW fiber laser cutting machine is driven by three factors: speed, thickness range, and secondary process elimination. The ability to cut 20mm aluminum at 5-8 meters per minute means that the throughput per shift is tripled compared to older 6kW technology. Furthermore, the edge quality provided by 30kW systems often eliminates the need for deburring or edge grinding, allowing parts to move directly from the laser bed to the welding or assembly station.

As the automotive industry shifts toward electric vehicles (EVs), the use of aluminum is skyrocketing to offset battery weight. Toluca is positioned at the heart of this shift. Investing in 30kW laser cutting technology is no longer an “optional upgrade” for local fabricators; it is a necessary requirement to meet the volume and precision demands of the next generation of transport manufacturing.

Conclusion: The Future of Fabrication in Toluca

The 30kW fiber laser cutting machine represents the pinnacle of current thermal cutting technology. For the aluminum alloy processing industry in Toluca, it offers a path toward unprecedented productivity. By understanding the interplay between high-power photonics and aluminum metallurgy, manufacturers can produce components that are cleaner, faster, and more cost-effective.

As we look toward the future, the integration of AI-driven nesting and real-time beam shaping will further enhance the capabilities of these 30kW systems. For now, the focus remains on precision, gas management, and maintaining the rigorous standards that have made Toluca a cornerstone of North American manufacturing. Embracing this technology ensures that the region remains a leader in the processing of complex, high-performance materials.