Engineering Overview: The 12kW Evolution in Monterrey’s Kitchenware Manufacturing

As a Senior Mechanical Engineer at PCL Group, I have observed a significant paradigm shift in the industrial landscape of Monterrey, Nuevo León. Monterrey has long been the industrial heartbeat of Mexico, but the recent surge in high-end kitchenware production—ranging from commercial-grade aluminum cookware to intricate modular shelving—has demanded a leap in fabrication technology. The introduction of the 12kW Commercial Grade Tube Laser Cutter represents more than just an upgrade in power; it is a fundamental shift in how we approach aluminum alloy processing. In an environment where precision, speed, and cost-per-part are the primary drivers of ROI, the 12kW fiber laser stands as the definitive solution for high-volume aluminum fabrication.

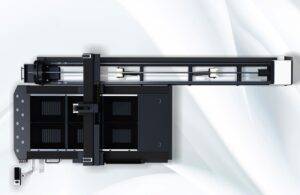

Structural Integrity: Plate-Welded Heavy Duty Bed and Thermal Treatment

The Science of the 600°C Annealing Process

From an engineering standpoint, the foundation of any high-precision laser system is its bed. For a 12kW system, the dynamic forces generated during high-speed acceleration and deceleration are immense. PCL Group utilizes a Plate-welded Heavy Duty Bed, which is engineered to withstand these inertial loads without compromising geometric accuracy. However, the welding process itself introduces significant internal residual stresses within the carbon steel structure. To mitigate this, our beds undergo a rigorous 600°C stress-relief annealing process in a high-temperature electric furnace.

This thermal treatment ensures that the molecular structure of the steel is stabilized. By slowly cooling the bed, we eliminate the risk of structural deformation over time—a common failure point in lower-tier machines. In the context of Monterrey’s fluctuating ambient temperatures, this structural stability is critical. A bed that is not properly annealed will “creep” over months of operation, leading to misalignment of the laser head and the chucks, ultimately resulting in scrapped aluminum parts. Our engineering standard ensures the bed remains stable for over 20 years of continuous industrial use.

Vibration Dampening and High-Speed Dynamics

The heavy-duty nature of the bed also serves as a massive vibration dampener. When cutting aluminum tubes for kitchenware—often involving thin-walled extrusions—vibration is the enemy of a clean finish. The mass of the PCL bed absorbs the harmonic frequencies generated by the high-speed servo motors, ensuring that the laser beam maintains a consistent focal point relative to the material surface. This is particularly vital when executing complex geometries or “frog-leap” movements between cut paths.

The CypCut & CypTube Control Ecosystem: Precision Redefined

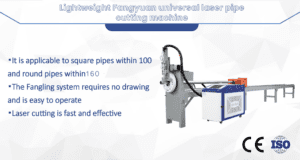

Hardware is only as capable as the software that directs it. For our 12kW tube laser systems, we integrate the CypCut/CypTube control system, which is widely regarded as the industry standard for fiber laser processing. For Monterrey’s kitchenware manufacturers, this system offers several high-level technical advantages:

Real-Time Compensation and Nesting Efficiency

Aluminum extrusions are rarely perfectly straight. The CypTube system utilizes advanced sensing technology to detect the actual position and rotation of the tube in real-time. It automatically compensates for “bow” or “twist” in the raw material, ensuring that every hole, slot, or notch is cut precisely where it belongs. Furthermore, the integrated nesting software optimizes material usage, which is a critical factor given the rising costs of high-grade aluminum alloys. Reducing waste by even 3-5% can result in tens of thousands of dollars in annual savings for high-volume producers.

Intelligent Corner Processing

When cutting square or rectangular aluminum tubes, the corners present a thermal challenge. The CypCut system employs intelligent power modulation, reducing the laser output as the head approaches a corner to prevent over-burning, and then instantly ramping back up to 12kW for the straightaways. This ensures a uniform cut quality across the entire profile of the tube, eliminating the need for secondary grinding or finishing—a major bottleneck in kitchenware assembly lines.

12kW Performance Analysis: Cutting Aluminum Alloy with Clean Compressed Air

Overcoming Reflectivity with High Power Density

Aluminum is a highly reflective and thermally conductive material. In lower power systems (1kW to 4kW), the laser beam can often be reflected back into the optics, causing damage and resulting in poor cut quality. The 12kW power level provides a “brute force” advantage. The power density is so high that it instantly couples with the material, transitioning from solid to vapor before reflection can occur. This allows for significantly higher cutting speeds on aluminum alloys (such as 3003, 5052, or 6061) which are common in the kitchenware industry.

The Economic Advantage of Clean Compressed Air

Traditionally, nitrogen was the go-to assist gas for aluminum to prevent oxidation. However, at 12kW, the cutting speed is so high that we can effectively use Clean Compressed Air. This is a game-changer for Monterrey manufacturers. By utilizing a high-pressure air compressor coupled with a sophisticated filtration and drying system (to ensure the air is oil-free and moisture-free), we can achieve a cut quality that is nearly identical to nitrogen but at a fraction of the operating cost.

The 12kW laser provides enough energy to blow away the molten aluminum quickly, resulting in a smooth, dross-free edge. For kitchenware—where aesthetics and hygiene are paramount—the ability to produce clean edges without the high overhead of liquid nitrogen tanks is a massive competitive advantage. Our engineering team at PCL assists clients in Monterrey to set up the correct air-to-power ratios to maximize this efficiency.

Critical Infrastructure: Industrial Voltage Regulators for Monterrey’s Grid

One of the most overlooked aspects of installing a 12kW laser in Monterrey is the stability of the local power grid. While Monterrey has robust industrial infrastructure, the sheer density of heavy manufacturing in zones like Santa Catarina, Apodaca, and Guadalupe can lead to voltage fluctuations, brownouts, and transient surges. A 12kW fiber laser source is a highly sensitive electronic component; even a minor voltage spike can cause catastrophic failure to the laser modules.

PCL Group mandates the use of a high-capacity Industrial Voltage Regulator for every 12kW installation in Mexico. This is not an optional luxury; it is a critical safeguard. The regulator acts as a buffer, ensuring that the machine receives a constant, clean 380V/440V supply regardless of what is happening on the external grid. This protects the IPG or Raycus laser source, the servo drivers, and the CNC controller, ensuring maximum uptime and protecting the client’s multi-million peso investment.

PCL Group’s Commitment: 24/7 Technical Support and Local Expertise

In the fast-paced kitchenware industry, downtime is the most expensive variable. If a machine stops, an entire production line for a major retailer might grind to a halt. This is why PCL Group has invested heavily in our 24/7 Technical Support infrastructure. We understand that Monterrey operates on a global clock, and our engineers are available around the clock to provide remote diagnostics and on-site assistance.

Our support goes beyond simple repairs. We provide ongoing process optimization, helping our Monterrey clients refine their cutting parameters for new aluminum alloys or complex tube profiles. Whether it is a software question regarding CypCut or a mechanical adjustment on the pneumatic chucks, our team is dedicated to ensuring that your 12kW tube laser remains a profit center, not a maintenance burden.

Conclusion: The Future of Aluminum Fabrication in Nuevo León

The integration of a Commercial Grade 12kW Tube Laser Cutter is a strategic move for any serious kitchenware manufacturer in Monterrey. By combining the structural rigidity of a 600°C annealed bed, the precision of the CypCut system, and the raw power of a 12kW source, PCL Group provides a tool that redefines productivity. When you factor in the operational savings of compressed air cutting and the security of an industrial voltage regulator, the technical and economic arguments become undeniable. At PCL, we don’t just sell machines; we provide the engineering foundation for Monterrey’s next generation of manufacturing excellence.