Menu

We use analytical cookies to improve your experience on our website

Steel Angle is one of the most popular hot rolled in steel structure, It is easy to weld, cut, form and machine.

Angle steel can be composed of various stress components according to different requirements of the structure, and can also be used as a connector between components.

Widely used in various building structures and engineering structures, such as beams, bridges, transmission towers, lifting and transportation machinery, ships, industrial furnaces, reaction towers, container shelves, cable trench supports, power pipelines, busbar support installation, warehouse shelves, etc.

Steel angle processing usually have drilling, marking, bevelling, Make holes like a punch or drill, miter cut, compound miter, bevel and cut to length.

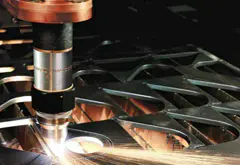

Plasma cutting machine is a mature technology in angle steel cutting, various solutions are effective,such as 5 axis tube plasma cutting machine, 8 axis beam and tube plasma cutting machine, H series plasma cutting machine

If choosing tube laser cutting machine, the marking, drilling, cutting will be better, but not suitable to bevel now. With the rotary system, the maximum cutting size can be 560mmX560mm

Angle plasma cutting and laser cutting are two different cutting processes, they have some differences in cutting principle, applicable materials, cutting speed, precision and application areas.

Cutting principle:

Angle steel plasma cutting: plasma cutting is the use of oxygen, nitrogen and other gases at high temperatures to form a plasma, the metal material is heated to the state of melting or vaporization, and then through the nozzle will be a high-speed plasma jet to the surface of the metal, so as to cut the metal material.

Laser cutting: Laser cutting is to use the high energy density of laser beam to locally heat the metal material to the melted or gasified state, and then blow away the melted or gasified material through the gas nozzle to realize the cutting process.

Applicable materials:

Angle steel plasma cutting: plasma cutting is suitable for thicker metal materials, especially for stainless steel, aluminum alloy and other materials with high reflectivity have advantages.

Laser cutting: laser cutting is suitable for thinner metal materials and some non-metallic materials, such as wood, plastic, etc.

Cutting speed:

Angle steel plasma cutting: plasma cutting usually has a high cutting speed, especially in thicker metal materials perform better.

Laser cutting: laser cutting speed is generally slower and may be slower especially when cutting thicker metals.

Cutting Accuracy:

Angle plasma cutting: plasma cutting may have a larger slag when cutting thicker metals, which affects cutting accuracy and may be less suitable for some applications that require higher cutting accuracy.

Laser cutting: laser cutting has high cutting accuracy, especially for thinner metal materials, very fine cutting can be realized.

Application areas:

Angle steel plasma cutting: plasma cutting is commonly used in metal structures, shipbuilding, heavy machinery and other fields, especially suitable for cutting thicker metal materials.

Laser cutting: laser cutting is widely used in electronics, automotive, aerospace and other fields, especially suitable for applications that require high cutting quality and precision.