3D ROBOT LASER CUTTING MACHINE

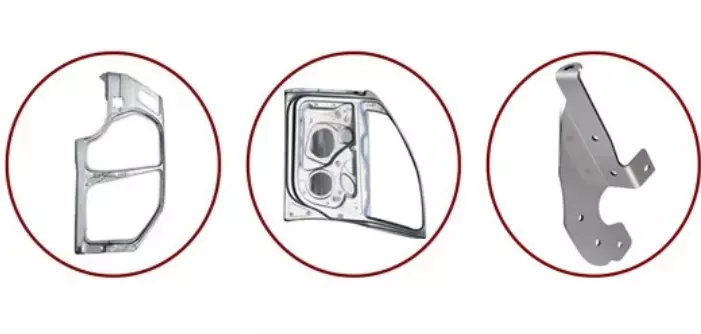

Industrial 6-axis robotic fiber laser system designed for 3D curved workpieces, thermoformed automotive parts, and complex metal structures. High flexibility for multi-dimensional cutting and trimming operations.

6-Axis Flexible Processing

Equipped with world-class industrial robot arms, the system provides high dynamic performance and path accuracy. It is the ideal solution for trimming and hole-cutting of 3D molded parts, replacing traditional punching dies.

The compact laser head design allows the robot to access tight spaces and process complex angles that are impossible for standard 5-axis machines.

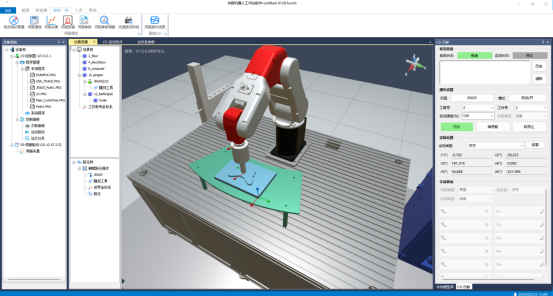

OPERATION DEMONSTRATION

6-Axis Robotic Arm performing high-precision edge trimming on a 3D automotive steel component.

Off-line Programming Support

Compatible with professional 3D laser cutting software (such as Robotmaster or SprutCAM). Users can perform trajectory planning and simulation on a PC, significantly reducing on-site debugging time.

The system features a non-contact height tracking sensor that maintains a constant gap between the nozzle and the metal surface, even on irregular curved contours.

Technical Support & FAQ

Our standard 3D laser systems are primarily integrated with FANUC or ABB robotic arms due to their high path accuracy and global service availability. However, we can also customize the integration for KUKA, Yaskawa, or Kawasaki robots depending on your factory's existing infrastructure.

The laser head is equipped with a high-speed non-contact capacitive sensor. This allows the robot to maintain a constant focal distance from the metal surface in real-time, effectively compensating for any slight deformation or positioning errors in the 3D workpiece.

Yes, we provide support for professional offline programming (OLP) environments. This enables engineers to perform path planning, collision detection, and 3D simulation on a PC before actual production, reducing machine downtime during part changeovers.

The robotic arm requires minimal maintenance compared to traditional 5-axis CNC machines. Routine inspections involve checking the grease levels in the reducers every 6,000 to 10,000 hours of operation and ensuring the internal cabling remains free of stress or wear.