Drag-teach robotic welding, also known as “drag-teach” welding, is an advanced solution that combines collaborative robots with simplified programming techniques. It is particularly suitable for small to medium-sized manufacturing enterprises and scenarios involving diverse, small-batch production. Its main advantages include:

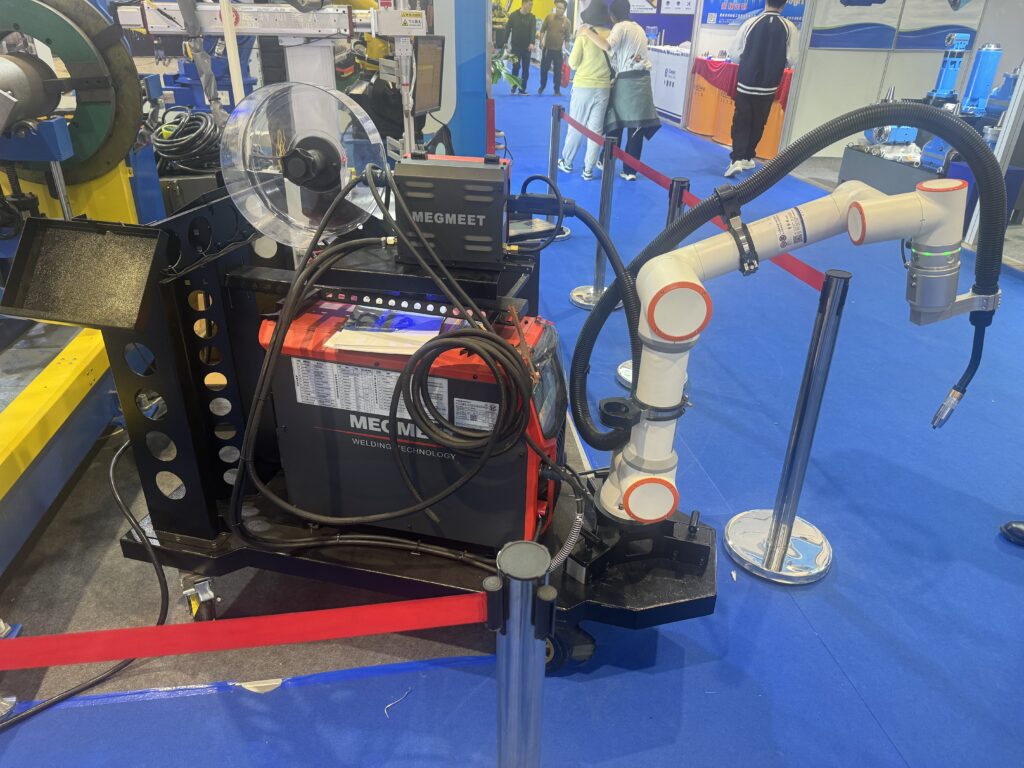

Ease of Operation and Reduced Technical Barriers Drag-teach technology allows operators to manually guide the robotic arm to welding positions, setting paths and parameters without complex programming knowledge. For instance, with integrated end-effector force control, users can gently drag the welding torch to the target point and establish welding tasks via end buttons, setting paths and arc initiation/termination. This approach enables even those without programming experience to quickly adapt, significantly lowering the operational threshold.

Enhanced Welding Quality and Consistency Through drag-teach, robots can precisely replicate operational paths, ensuring consistent and high-quality welds. Additionally, by integrating arc tracking and laser seam tracking technologies, robots can correct path deviations in real-time, maintaining the welding torch at the center of the seam and improving welding accuracy.

Flexibility to Meet Diverse Production Needs Drag-teach robotic welding systems are highly adaptable, capable of quickly adjusting to various workpiece shapes and sizes, making them ideal for multi-variety, small-batch production models. With a straightforward teaching process, users can swiftly switch welding tasks, shortening product modification cycles and reducing equipment investment.

Increased Production Efficiency and Reduced Labor Intensity Robots can operate continuously for 24 hours, significantly boosting production efficiency. Meanwhile, operators only need to handle workpiece loading and unloading, staying away from welding arcs, fumes, and splatter, thereby improving working conditions and reducing labor intensity.

Lower Operational Costs Although the initial investment may be higher, drag-teach robotic welding systems can substantially reduce operational costs in the long run by enhancing production efficiency, minimizing human errors, and decreasing rework rates. Furthermore, these systems can significantly reduce material waste and energy consumption, further lowering production costs.

In summary, drag-teach robotic welding, with its ease of operation, high quality, efficiency, and adaptability, has become an ideal choice for modern manufacturing to enhance welding automation levels.