The application of TCP (Tool Center Point) technology in laser cutting H-beam is mainly reflected in the dynamic control of the position and attitude of the laser cutting head through high precision, in order to adapt to the needs of three-dimensional contour cutting of complex workpieces. The following are the specific applications and advantages of TCP technology in laser cutting H-beams:

1. Basic principle of TCP technology

TCP technology ensures that the focal point of the laser beam (the center point of the tool) always accurately tracks the preset cutting path by adjusting the spatial position and angle of the laser cutting head in real time. Its core includes:

— Dynamic positioning: real-time detection of the workpiece position by means of sensors or vision systems.

— Multi-axis linkage: control of multiple axes of motion (X/Y/Z + rotary axes) of a robotic arm or CNC machine tool to achieve six degrees of freedom (6DoF) adjustment of the cutting head.

— Path Compensation: Automatically compensates path deviation due to workpiece deformation, assembly error or thermal deformation.

2. Specific applications in H-beam cutting

(1) Adaptive complex cross-section shapes

The flange (flange) and web (web) of H-beam constitute a non-continuous plane, and traditional cutting requires multiple positioning. TCP technology can realize:

— Automatic attitude adjustment: the cutting head is dynamically tilted according to the geometrical characteristics of the H-beam, keeping the laser beam perpendicular to the cutting surface (e.g. when cutting flanges diagonally).

— Continuous Cutting: No need for segmented operation to complete the cutting of shaped holes, bevels or end contours of flanges and webs in one go.

Handling of assembly error and deformation

H-beams may have distortions or dimensional deviations during processing or installation, and TCP technology responds to them in the following ways:

— Real-time deviation correction: dynamic correction of the cutting path through laser ranging or visual feedback.

— 3D scanning modeling: pre-scanning the actual shape of the workpiece to generate an adapted cutting program.

High-precision Bevel Cutting

H-beam welding often requires beveling (e.g. K-shape, V-shape beveling), TCP technology can:

— Angle precision control: Adjust the inclination angle of the cutting head to realize the cutting of different bevel angles (e.g. 45° bevel cutting).

— Variable Angle Cutting: Complete seamless transition of multi-angle bevels on a single workpiece.

Automation Integration

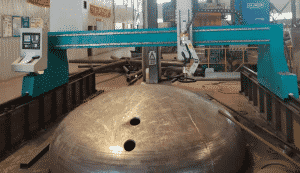

— Collaboration with robots: 6-axis robots equipped with TCP technology can flexibly cut large H-beam components for construction, bridge and other scenarios.

— Offline Programming: 3D cutting paths are generated by CAD/CAM software and directly imported into the control system, reducing manual instruction time.

3. Technical Advantages

-Precision enhancement: Cutting precision can reach ±0.1mm, reducing subsequent trimming workload.

— Efficiency optimization: Reduce workpiece repetitive positioning and fixture adjustment time.

— Flexibility: Adapt to the customized cutting of H-beams of different specifications (e.g. variable cross-section or non-standard parts).

— Material saving: Improve material utilization through path optimization and scrap reduction.

—

4. Key technical support

— High dynamic response servo system: ensures fast tracking of complex trajectories by the cutting head.

— Real-time sensing feedback: laser displacement sensors or vision systems for workpiece positioning.

— Intelligent software algorithms: path planning, collision detection and thermal deformation compensation algorithms.5. Examples of application scenarios

— Construction steel structure: cutting connection nodes of H-beam beams and columns.

— Shipbuilding: processing shaped holes for hull reinforcement.

— Heavy machinery: 3D cutting of customized H-beam supports.

6. Challenges and Future Directions

— Cost: High initial investment for high precision TCP system.

— Process database: Need to accumulate cutting parameters for different materials (e.g., high-strength steel).

— Intelligent development: Combine with AI to realize adaptive cutting parameter adjustment and defect detection.

—

Summarize

TCP technology solves the problems of precision and efficiency in three-dimensional cutting of H-beams by dynamically controlling the spatial attitude of the laser cutting head, which is especially suitable for complex node and bevel processing. With the progress of robot technology and intelligent algorithms, TCP will play a greater role in the automated processing of steel structure.