Offshore Oil Platform Welding and the Application of Intelligent Welding Robots

Offshore oil platforms are constructed using a large amount of welded steel structures, and the harsh marine service environment imposes higher requirements on steel structure welding.

Traditional offshore platform construction primarily relies on manual welding, with semi-automatic welding as an auxiliary method. However, ensuring the consistency of weld quality and welding efficiency is challenging. Additionally, the shortage of skilled welders has increased the difficulty of production organization, reduced manufacturing precision, and led to high production costs and energy consumption.

Intelligent robotic welding is a crucial approach to achieving efficient and high-quality welding of offshore steel structures. Robotic welding offers advantages such as stable quality, high welding efficiency, and lower overall costs, making it highly promising for engineering applications. Various mature products are available worldwide. For instance, Germany’s KUKA has developed a welding robot system with an end payload capacity of up to 16 kg and a repeat positioning accuracy of ±0.05 mm, which allows for a broad operational range and the ability to weld various types of seams. Japan’s FANUC has integrated its advanced CNC, servo, and factory automation technologies into the development and production of robots. Its M-10 and M-20 series welding robots, widely used in the automotive parts industry, have seen the delivery of over one million units. Switzerland’s ABB has installed over ten thousand arc welding robots, which are widely used due to their robust and stable structure and positioning accuracy of up to ±0.05 mm.

Currently, most welding operations still rely on repetitive teaching for welding robots. However, due to the large size and complex shapes of offshore steel structures, repetitive teaching is difficult and time-consuming. Moreover, once robot programming is completed, the robot cannot adapt to uncertainties in the workpiece position, making it unable to adjust for manual positioning errors and part discrepancies in real time.

This paper analyzes the current application status and challenges of welding robots in steel structure manufacturing based on the characteristics of offshore steel structures. It also examines the key technologies for intelligent welding robots in steel structure welding, providing a reference for offshore steel structure welding in China.

Current Status of Offshore Steel Structure Welding

1 Workpiece Characteristics

Offshore steel structures mainly include structural load-bearing components such as jackets and modules, as well as process pipelines and subsea pipelines for transporting media.

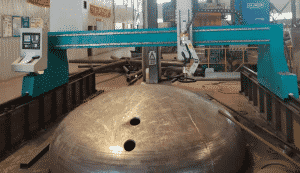

The construction process of a jacket involves prefabricating and extending braces and jacket legs, followed by spatial assembly and welding of T/K/Y joints. The primary welding form is a saddle-shaped groove, characterized by complex welding trajectories and heavy workloads. The pipe wall thickness can reach up to 75 mm, significantly increasing welding difficulty.

Module structures mainly include ring plates, flange replacement plates, web replacement plates, tubular stiffeners, stiffeners, elliptical tubes, and insert plates. The main welding forms include straight grooves and fillet welds, involving thick plate double-sided groove welding in various positions such as flat, horizontal, vertical, and overhead. The wall thickness typically ranges from 13 to 60 mm, with most applications falling within the 16–25 mm range.

Deepwater reinforcement rings and collapse rings primarily use V-groove, K-groove, and fillet welds, requiring full-penetration multi-layer multi-pass welding for the grooves and fillet welds. The thickness of reinforcement rings can reach 70 mm, with a maximum root gap of 5 mm. The current process mainly involves vertical welding with reverse deformation using semi-automatic CO₂ welding carriages. For reinforcement rings with a 50 mm wall thickness, robotic welding has been achieved through manual teaching. However, significant challenges remain in fully automated root sealing and multi-layer multi-pass automatic welding.

From the above analysis, offshore steel structures have characteristics such as large dimensions, thick pipe walls, complex welding trajectories, and diverse welding structures and joints. These factors make it difficult to ensure precision during processing. Additionally, during steel structure construction, the “workshop prefabrication and on-site assembly” approach is generally adopted. In the prefabrication stage, parts must be assembled and positioned using tack welding, which inevitably introduces assembly errors, particularly in weld gap and misalignment. These factors make it difficult to ensure stable weld quality.

Furthermore, due to the harsh offshore service environment—including typhoons, ice floes, seawater erosion, and corrosion—offshore steel structures must withstand extreme conditions. They require high resistance to low-temperature impact, fatigue, and fracture toughness. Consequently, robotic welding technology must meet extremely high requirements in terms of welding quality, structural complexity, component diversity, and assembly precision.

2 Welding Status

Currently, steel structure welding is mainly divided into traditional manual welding, semi-automatic welding, and robotic welding. Semi-automatic welding generally involves changing the workpiece’s position while keeping the welding torch’s posture relatively fixed. During welding, workers must manually adjust the torch position and welding parameters based on actual conditions.

Welding robots still primarily use the “teaching-playback” mode, requiring operators to manually guide the robot along the weld path once before storing the path in the robot controller for repetitive execution during production. This method can only repeat pre-taught paths and lacks flexibility in handling changes in welding tasks. If welding parameters, paths, or speeds need adjustments, the robot must be re-taught, increasing welding workload and time costs.

In offshore steel structure construction, process pipeline welding can already achieve manual root sealing and automatic filling using specialized welding machines. However, for complex structural component welding, manual root sealing and semi-automatic filling are still the primary methods.

With the increasing demand for robotic welding in field applications, manual guidance teaching and offline programming methods have emerged. While these robots simplify operation and reduce the time cost of manual teaching, they do not fundamentally solve the problem of poor adaptability in teaching programming. For different weld shapes or positions, re-teaching is still required. Additionally, robots lack environmental perception capabilities, making it difficult to achieve fully automated welding for complex welds, which limits their application in offshore steel structure welding.

The core of intelligent welding robots lies in accurately obtaining, processing, and executing welding-related information to mimic human observation and actions for intelligent welding. With the development of sensing technology, welding robots can use sensors (e.g., vision and tactile) to collect information about workpiece morphology and position. This data is fed back to the robot controller to achieve weld seam recognition, intelligent parameter matching, and trajectory correction, enabling real-time adjustments to the torch’s posture and welding parameters.